Method for preparing Kevlar nanofiber enhanced flexible solid linear supercapacitor

A supercapacitor, Kevlar fiber technology, applied in capacitor manufacturing, capacitors, hybrid capacitor electrolytes, etc., can solve the problems of limited mechanical strength and low mechanical properties of gels, and achieve high product quality, low cost, and improved strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

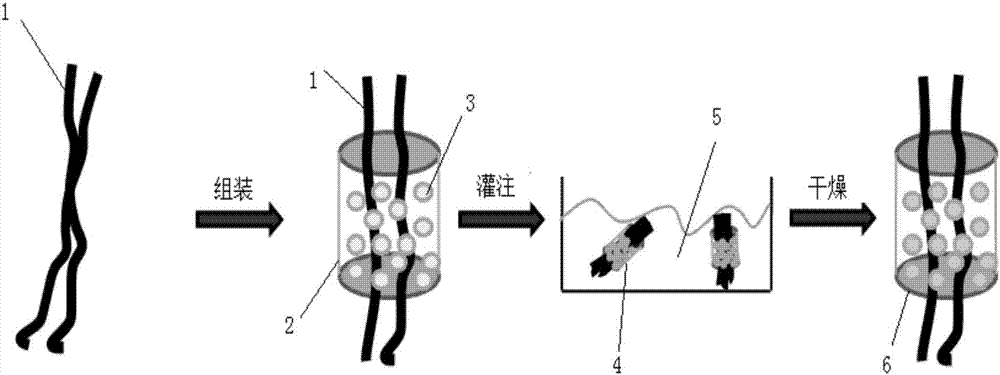

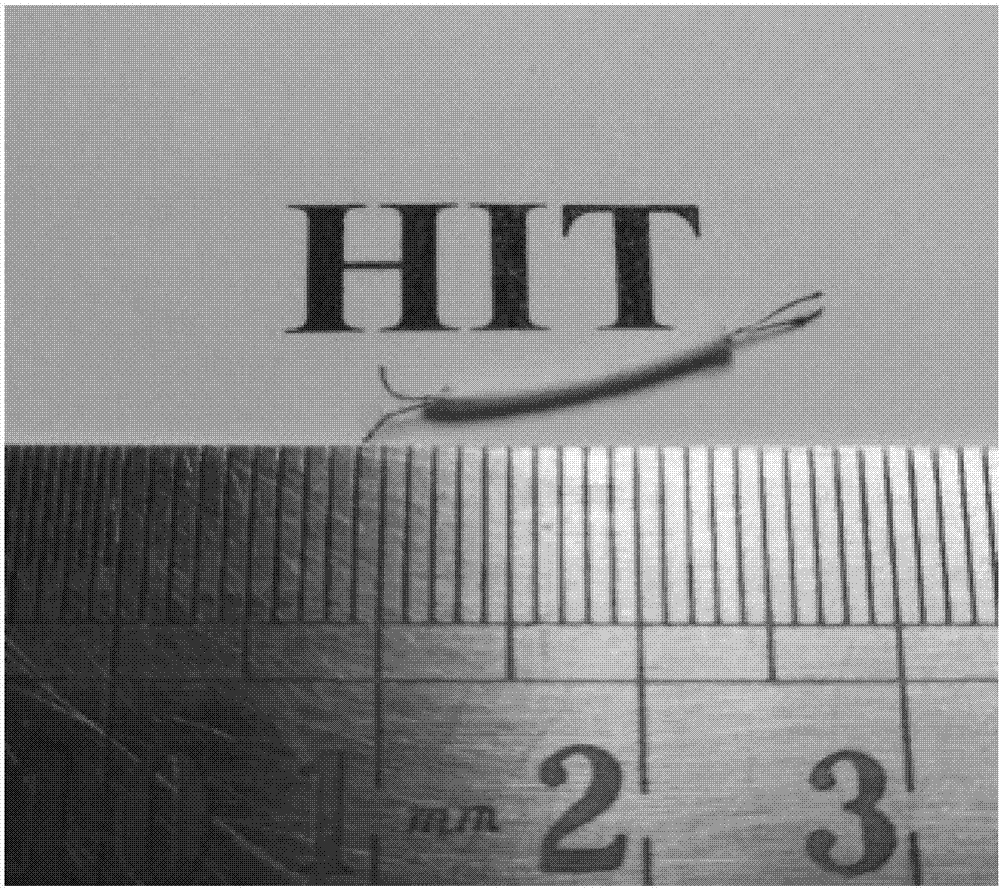

[0036] Specific implementation mode one: combine figure 1 Specifically explaining this embodiment, a method for preparing a Kevlar nanofiber-reinforced flexible solid-state linear supercapacitor described in this embodiment is carried out according to the following steps:

[0037] 1. Preparation of Kevlar nanofibers:

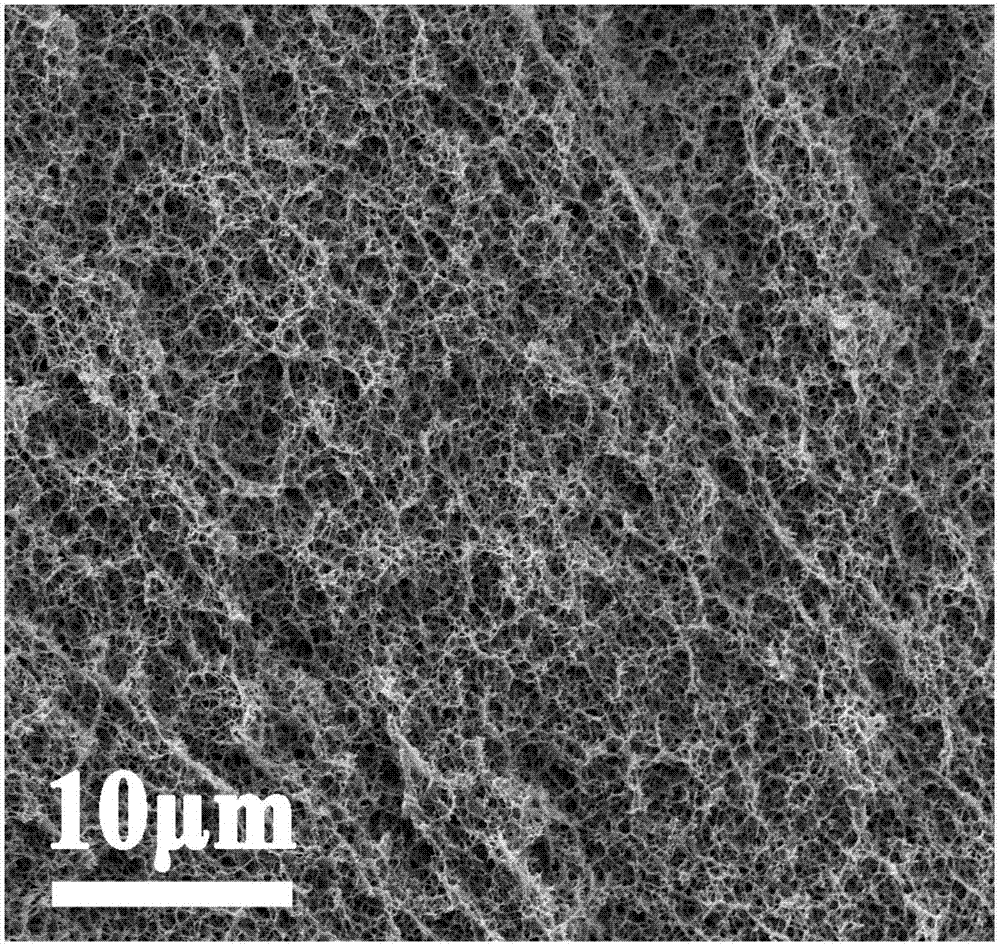

[0038] Take the Kevlar pulp and dry it in a vacuum drying oven for 12h to 24h to obtain the dried Kevlar fiber. Put potassium tert-butoxide and the dried Kevlar fiber in the dimethyl sulfoxide / methanol mixture , magnetically stirred for 2 to 7 days to obtain a deep red Kevlar nano solution;

[0039] The mass ratio of the potassium tert-butoxide to the dried Kevlar fiber is (0.5~1):1;

[0040] The mass of potassium tert-butoxide and the volume ratio of dimethyl sulfoxide / methanol mixed solution are (5~15) g:200mL;

[0041] The volume ratio of dimethyl sulfoxide to methanol in the dimethyl sulfoxide / methanol mixture is (20~60):1;

[0042] Second, the assembly ...

specific Embodiment approach 2

[0056] Embodiment 2: This embodiment differs from Embodiment 1 in that the molecular weight of polyvinyl alcohol described in Step 3 is 80,000-160,000. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0057] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step one, Kevlar pulp is dried in a vacuum oven for 24 hours to obtain dried Kevlar fiber, and tert-butyl Potassium alkoxide and dried Kevlar fibers were placed in a mixed solution of dimethyl sulfoxide / methanol and magnetically stirred for 7 days to obtain a dark red Kevlar nano solution. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com