Lithium ion battery positive plate and preparation method thereof

A lithium-ion battery and positive electrode technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of poor safety performance of lithium-ion battery positive electrodes, avoid internal short circuits, improve safety performance, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

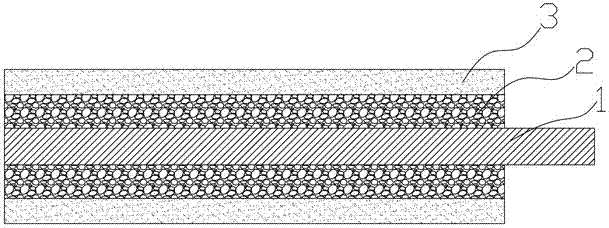

[0027] Such as figure 1 A positive electrode sheet of a lithium ion battery is shown, comprising a positive electrode current collector 1, the surface of the positive electrode current collector is coated with a positive electrode material layer 2, the surface of the positive electrode material layer is coated with a separator layer 3, and the positive electrode material layer is composed of the following components in mass percentage Made: 55% positive electrode active material (nickel cobalt lithium manganese oxide), 3% first binder (polyvinylidene fluoride), 1% conductive agent (conductive carbon black), and the balance is the first organic solvent (N- methylpyrrolidone); the isolation layer is made of the following components by mass percentage: 62% nano-silica, 1.5% second binder (polyvinylidene fluoride), 0.5% sodium naphthalenesulfonate formaldehyde condensate, 1% ethanol, and the balance is the second organic solvent (N-methylpyrrolidone).

[0028] The positive electr...

Embodiment 2

[0034] Such as figure 1 A positive electrode sheet of a lithium ion battery is shown, comprising a positive electrode current collector 1, the surface of the positive electrode current collector is coated with a positive electrode material layer 2, the surface of the positive electrode material layer is coated with a separator layer 3, and the positive electrode material layer is composed of the following components in mass percentage Made: 60% positive electrode active material (nickel cobalt lithium manganate), 5% first binder (polytetrafluoroethylene), 3% conductive agent (conductive graphite), and the balance is the first organic solvent (N-formazan base pyrrolidone); the isolation layer is made of the following components by mass percentage: 65% nano-silica, 2% second binder (polytetrafluoroethylene), 1% sodium naphthalenesulfonate formaldehyde condensate, 3% ethanol , and the balance is the second organic solvent (N-methylpyrrolidone).

[0035] The positive electrode sh...

Embodiment 3

[0041] Such as figure 1 A positive electrode sheet of a lithium ion battery is shown, comprising a positive electrode current collector 1, the surface of the positive electrode current collector is coated with a positive electrode material layer 2, the surface of the positive electrode material layer is coated with a separator layer 3, and the positive electrode material layer is composed of the following components in mass percentage Made: 58% positive electrode active material (nickel cobalt lithium manganese oxide), 4% first binder (mass ratio of polyvinylidene fluoride to polytetrafluoroethylene 1:1), 1~3% conductive agent (conductive carbon black and conductive graphite mass ratio 1:2), the balance is the first organic solvent (N-methylpyrrolidone); the isolation layer is made of the following components by mass percentage: 63% nano-silica, 1.8% second bond agent (polyvinylidene fluoride and polytetrafluoroethylene mass ratio 1:1), 0.6% sodium naphthalenesulfonate formald...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com