Hybrid stepping motor of installing permanent magnet on stator

A stepper motor and stepper motor technology, applied in the shape/style/structure of winding conductors, magnetic circuit shape/style/structure, electrical components, etc., can solve the difficulty of processing and installing permanent magnets and maintenance, and the inconvenience of cooling and heat dissipation of permanent magnets , motor structure and drive complexity, etc., to achieve the effect of simple manufacturing process, simplified processing and assembly process, and simplified processing and assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is a detailed description of the embodiments of the present invention. This embodiment is carried out based on the technical solution of the present invention, and provides detailed implementation methods and specific operation processes.

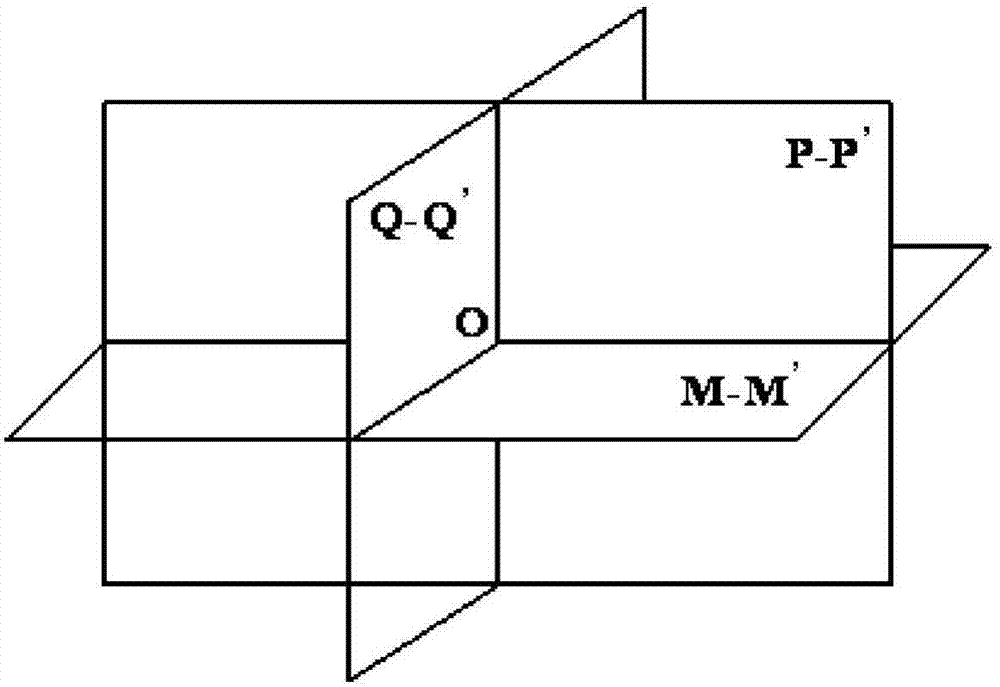

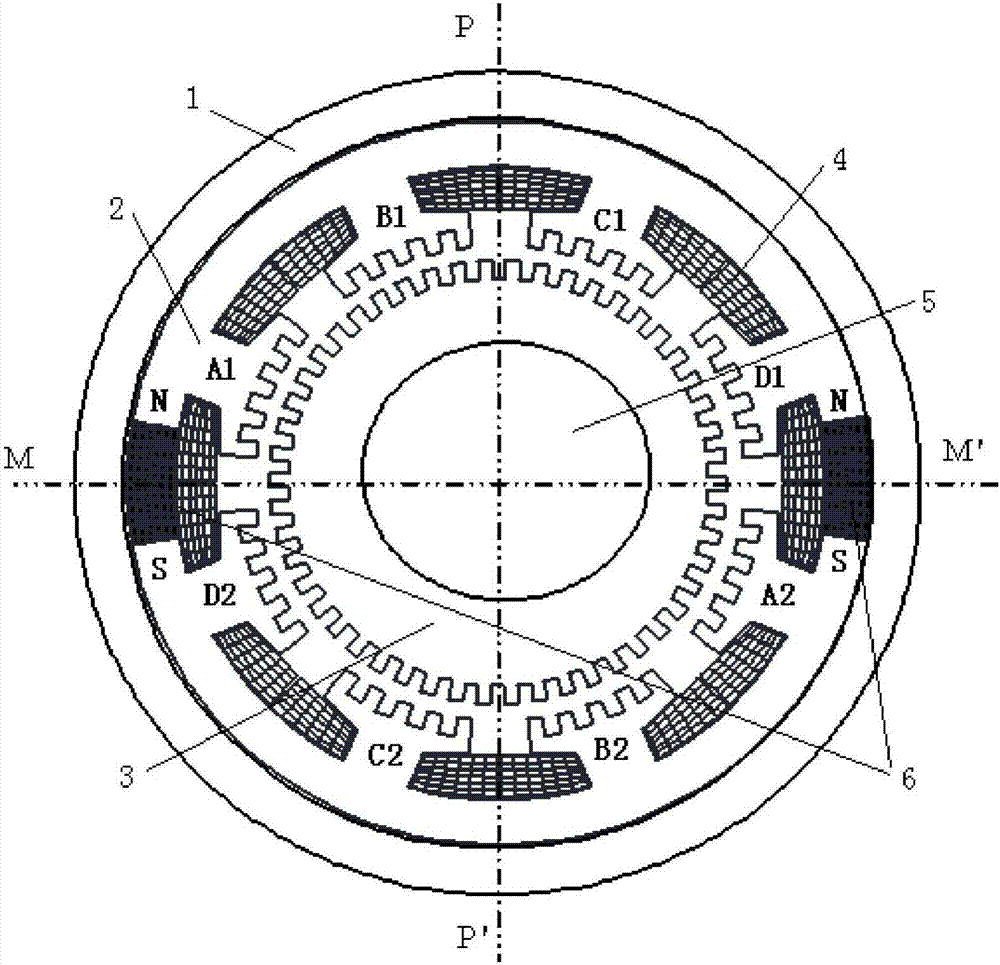

[0028] attached Figure 1~5 It is a schematic diagram of the structure of the four-phase hybrid stepper motor adopting the technical solution, figure 1 is the outline drawing of the motor, figure 2 The relationship between the planes used for the section, P-P', Q-Q', M-M' are two mutually perpendicular planes, and their common intersection point O is located at the center of the motor, and the P-P' plane and M The -M' plane is a vertical plane and a horizontal plane passing through the motor shaft respectively, and the Q-Q' plane is a plane perpendicular to the shaft. image 3 is a cross-sectional view along the Q-Q’ plane, Figure 4 is a cross-sectional view along the P-P' plane, Figure 5 It is a cross-sectional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com