Gonadotropin releasing hormone compound carrying sustained-release microsphere and preparation method thereof

A gonadotropin and hormone-releasing technology, applied in sexual diseases, microcapsules, drug combinations, etc., can solve the problems of pain and discomfort of patients, low drug loading rate, increase of microspheres, etc., so as to improve the drug loading rate. , the effect of reducing drug escape and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

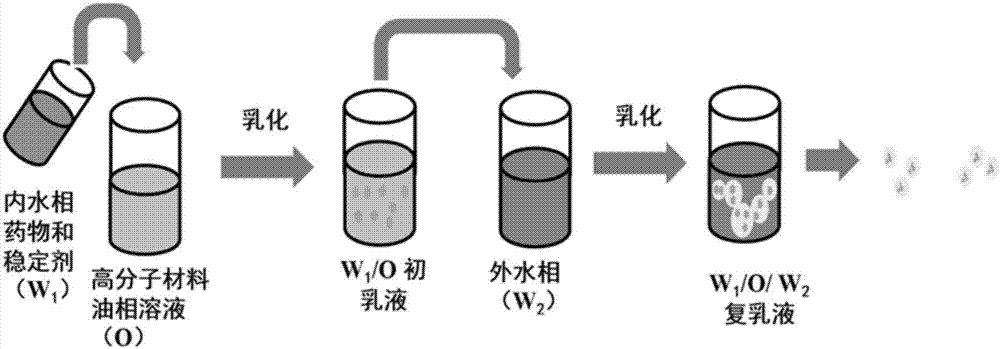

Method used

Image

Examples

Embodiment 1

[0052] A preparation method for embedding triptorelin acetate long-acting sustained-release microspheres for injection, comprising the steps of:

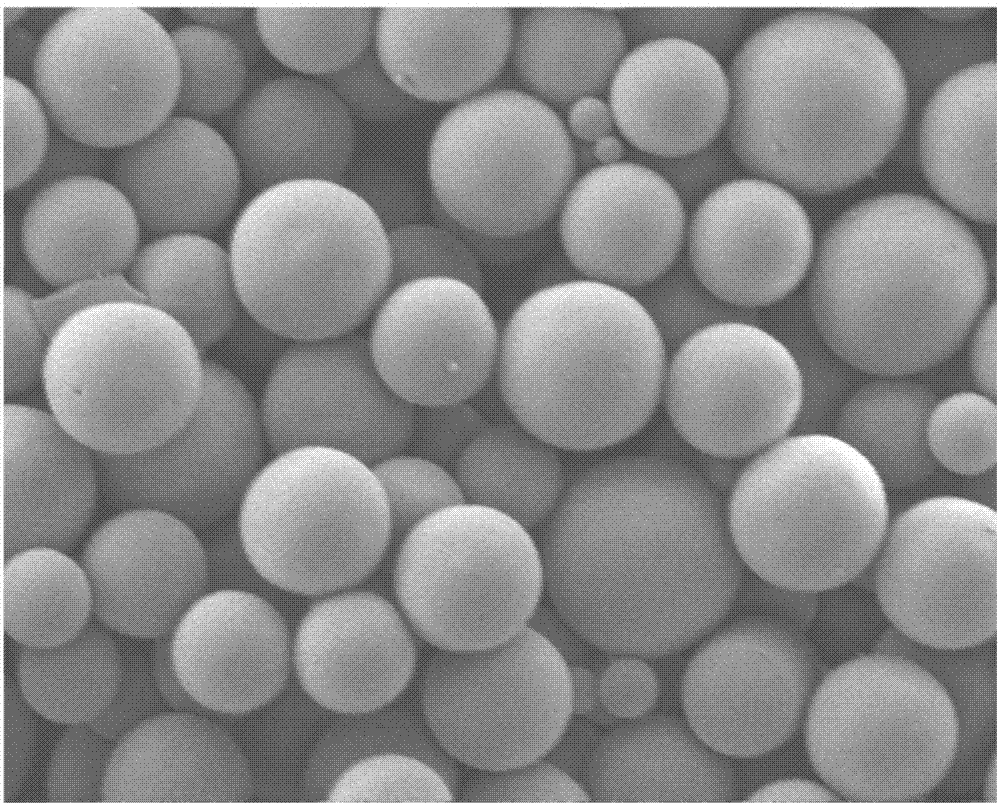

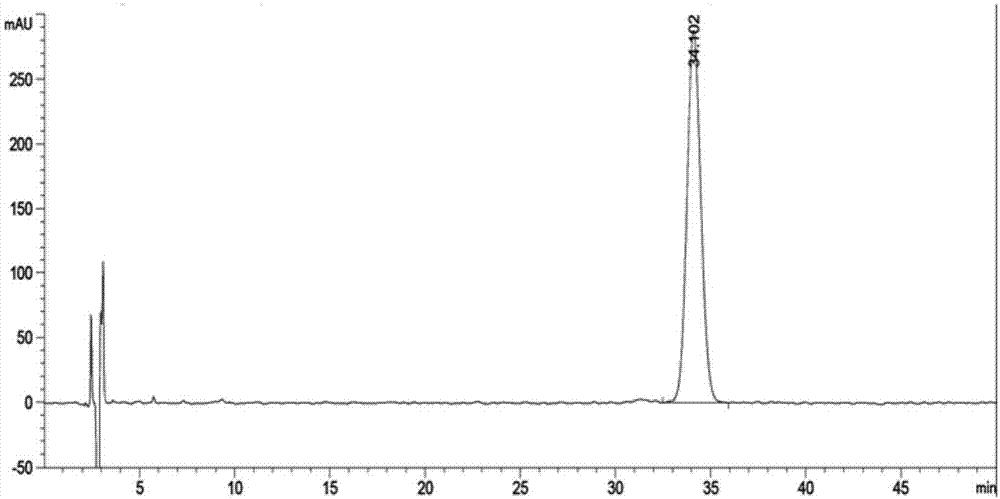

[0053] 5 mL of triptorelin acetate aqueous solution with a concentration of 20 mg / mL was used as the internal water phase, 10 mg / mL of trehalose was added as a stabilizer, and 1 g of polylactic-co-glycolic acid (PLGA) with a molecular weight of 20,000 was dissolved in 30 mL Acetone, as the oil phase. The inner water phase and the oil phase were mixed, and the homogenizer was emulsified at 15,000 rpm for 1 min to obtain W / O colostrum. Add the colostrum to 300mL of 5wt% PVA and 1wt% sodium chloride aqueous solution, mechanically stir at 300rpm for 5min to prepare double emulsion, solidify at 40°C for 3h, and form embedded triptorelin long-acting sustained-release microspheres , and then centrifuged and washed to obtain the drug-loaded microspheres. Sorbitol was added as a lyoprotectant, and the obtained microspheres were vacuum-drie...

Embodiment 2

[0065] A preparation method for embedding triptorelin long-acting sustained-release microspheres for injection, comprising the steps of:

[0066] 5mL concentration of 10mg / mL triptorelin aqueous solution is used as the inner water phase, 10mg / mL of mannitol is dissolved in the inner water phase, and 500mg of polyethylene glycol-modified polylactic acid-glycolic acid copolymer with a molecular weight of 30,000 (PEG-PLGA) was dissolved in 10 mL of ethyl acetate (EtAc) as the oil phase. The inner water phase and the oil phase were mixed, and the homogenizer was emulsified at 10,000 rpm for 2 minutes to obtain W / O colostrum. Add this colostrum to 400mL of 2%wt PVA and 1%wt sodium chloride aqueous solution, stir mechanically at 500rpm for 5min to prepare double emulsion, and solidify at 42°C for 6h to form embedded triptorelin long-acting sustained release The microspheres are centrifuged and washed to obtain the drug-loaded microspheres. Mannitol was added as a lyoprotectant, an...

Embodiment 3

[0076] A preparation method for embedding triptorelin acetate long-acting sustained-release microspheres for injection, comprising the steps of:

[0077] 1 mL concentration of 10 mg / mL triptorelin acetate aqueous solution was used as the inner water phase, 20 mg / mL trehalose was dissolved in the inner water phase as a stabilizer, and 200 mg of polyethylene glycol-modified polylactic acid (PELA) with a molecular weight of 200 mg was dissolved in 20mL dichloromethane, as the oil phase. Mix the inner water phase and the oil phase, and emulsify for 1 min at a speed of 20,000 rpm in a homogenizer to obtain W / O colostrum. Add the colostrum to 100mL of 1%wt PVA and 2%wt sodium chloride aqueous solution, stir mechanically at 500rpm for 3min to prepare double emulsion, obtain double emulsion, and solidify at 50°C for 6h to form embedding koji Prelin long-acting sustained-release microspheres are centrifuged and washed to obtain drug-loaded microspheres. Sorbitol was added as a lyopro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com