Rework glue and application thereof in removing LOCA (liquid optical clear adhesive) residue on rework TP (touch panel)

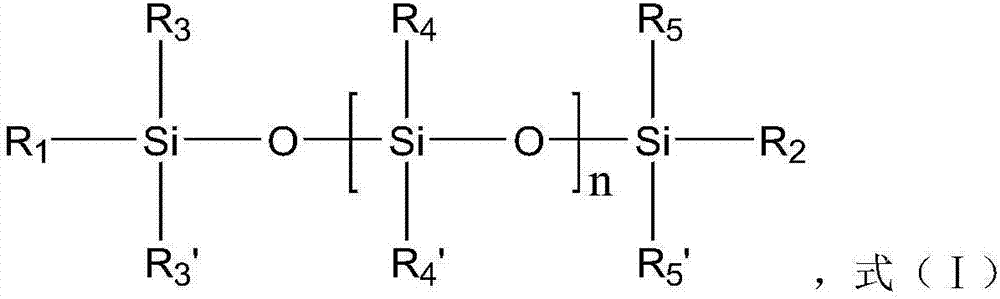

A technology of glue and vinyl silicone oil, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve problems such as foreign matter, affecting secondary utilization, and damaging TP precision circuits and components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] The preparation method of rework glue in embodiment and comparative example is as follows:

[0058] (1) Ingredients: Weigh modified vinyl silicone oil, reinforcing agent, and catalyst in proportion to obtain Group A ingredients, and weigh chain extender, hydrogen-containing silicone oil, additives and inhibitors in proportion to obtain Group B ingredients;

[0059] (2) Blending preparation: add the A and B components obtained in step (1) into different dynamic mixers respectively, under the environment with a vacuum degree of -0.08~-0.05MPa and a temperature of 25~35℃ Stir at a speed of 200~1200r / min for 0.5~1.5h, the obtained product is filtered and packed into designated containers;

[0060] (3) Degassing and subpackaging: the components treated in step (2) are placed in a high-speed degassing machine, degassed at a speed of 2500~5000r / min, and finally packaged through a sealed pipeline to obtain the degassing agent of the present invention. Rework glue.

[0061] Th...

Embodiment 4~6

[0110] Examples 4-6, Comparative Example 4-1, Comparative Example 4-2, Comparative Example 4-3, Comparative Example 4-4, according to the formula in Table 2, the rework glue was prepared, and the preparation method was as follows:

[0111] (1) Ingredients: Weigh modified vinyl silicone oil, reinforcing agent, and catalyst in proportion to obtain Group A ingredients, and weigh chain extender, hydrogen-containing silicone oil, additives and inhibitors in proportion to obtain Group B ingredients;

[0112] (2) Blending preparation: add the ingredients of A and B components obtained in step (1) into different dynamic mixers respectively, at a speed of 200r / min under the environment with a vacuum degree of -0.08MPa and a temperature of 35°C Stir for 1.5h, the resulting product is filtered and packed into designated containers;

[0113] (3) Degassing and packaging: the components after step (2) are placed in a high-speed degassing machine, degassed at a speed of 5000r / min, and finall...

Embodiment 7~9

[0116] Embodiment 7~9, comparative example 7-1, comparative example 7-2, comparative example 7-3, comparative example 7-4, prepare rework glue by the formula of table 3, preparation method is as follows:

[0117] (1) Ingredients: Weigh modified vinyl silicone oil, reinforcing agent, and catalyst in proportion to obtain Group A ingredients, and weigh chain extender, hydrogen-containing silicone oil, additives and inhibitors in proportion to obtain Group B ingredients;

[0118] (2) Blending preparation: Add the ingredients of A and B components obtained in step (1) into different dynamic mixers respectively, and use the speed of 1200r / min under the environment with a vacuum degree of -0.05MPa and a temperature of 25°C Stir for 0.5h, the resulting product is filtered and packed into designated containers;

[0119] (3) Degassing and subpackaging: the components after step (2) treatment are placed in a high-speed defoaming machine, degassed at a speed of 2500r / min, and finally pack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com