Long-fiber knitted vacuum insulation core material and preparation method thereof

A vacuum insulation, long fiber technology, used in heat exchange equipment, mechanical equipment, pipeline protection through heat insulation, etc., can solve the problem of short fibers easily pierced barrier bags, etc., to achieve low thermal conductivity, high thermal resistance, good flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

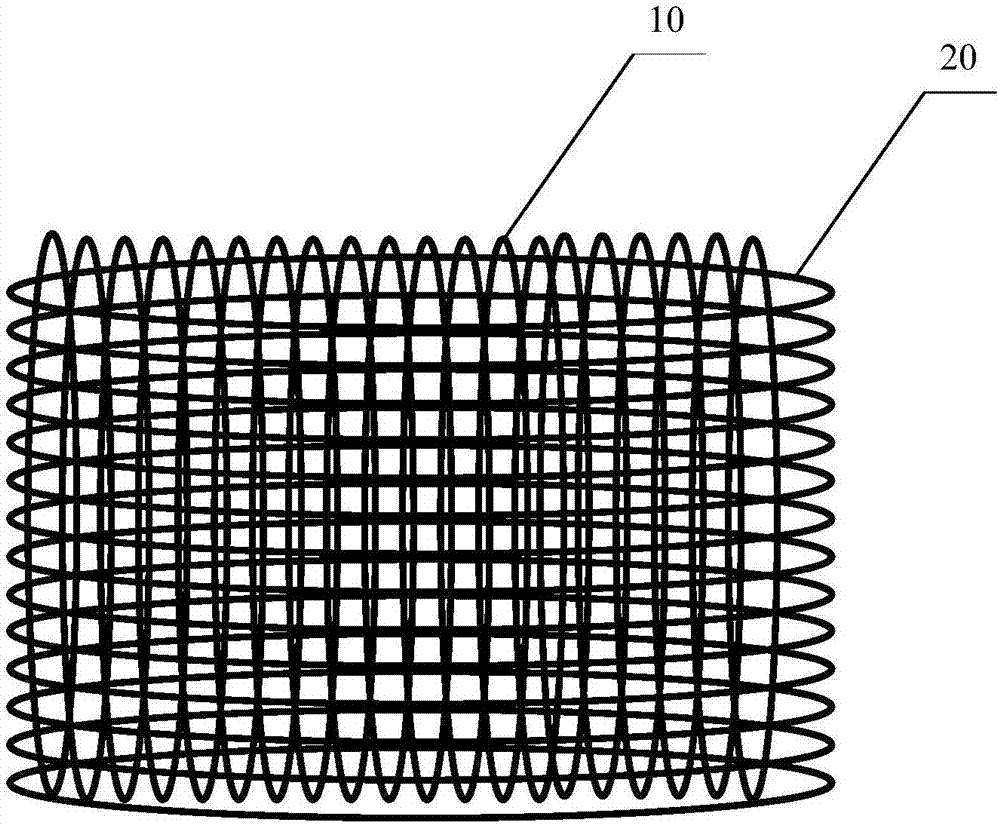

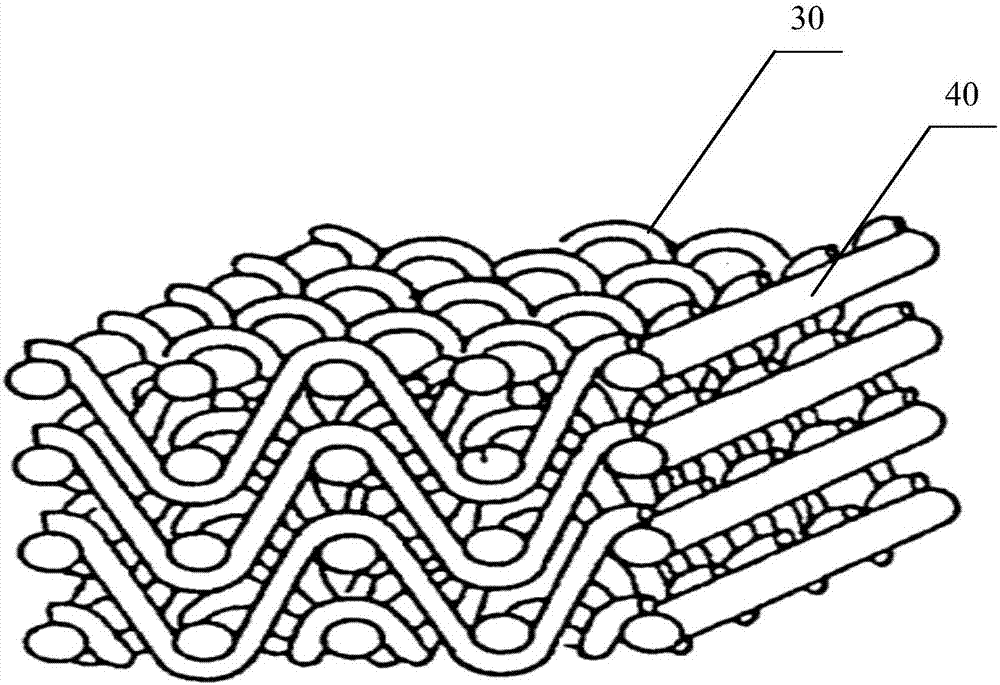

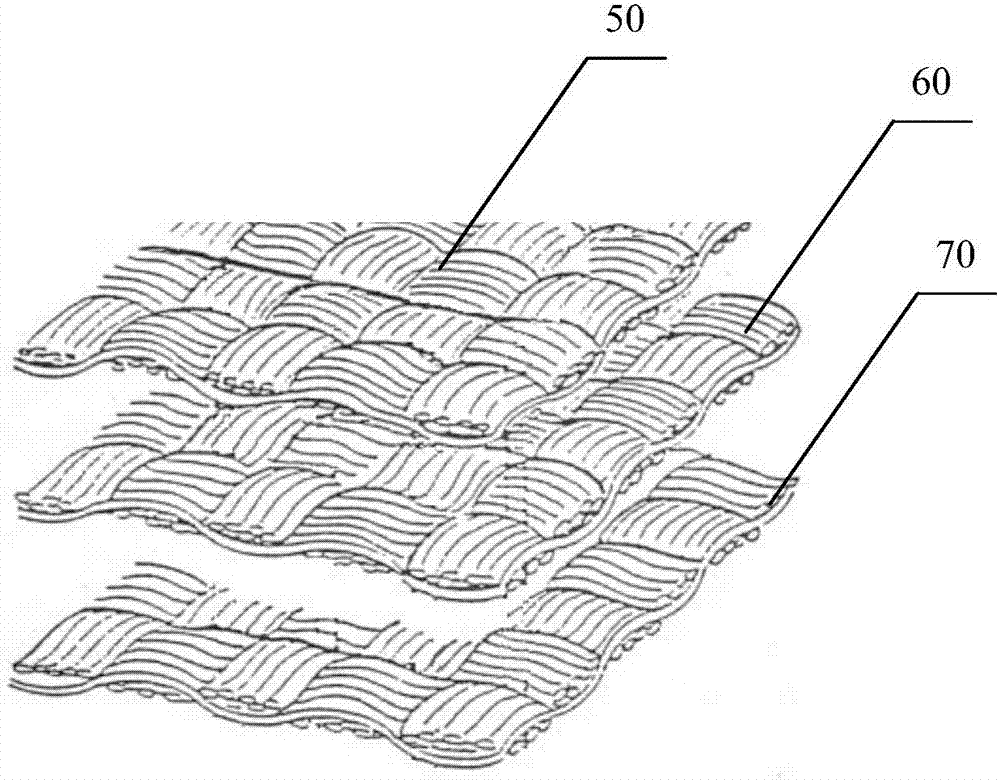

[0027] A long-fiber braided vacuum insulation core material, the chemical composition of which is: 68.0% SiO by mass percentage 2 , 5.0% Al 2 o 3 , 6.5% B 2 o 3 , 1.0% ZnO, 1.0% ZrO 2 , alkali metal oxide K 2 O and Na 2 The sum of O is 10.0%, and the sum of alkaline earth metal oxides MgO, CaO and BaO is 8.5%. The core material has 10 layers, a single layer thickness of 5 mm, and a fiber diameter of 6.0 μm. The single-layer unit cell structure of the core material is rectangular, and the unit cell pore size is 7.0 μm×7.0 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com