Ethylene glycol-based magnetic fluid composite film and preparation method thereof

A ethylene glycol, magnetic fluid technology, applied in the direction of magnetic objects, magnetic films, magnetic liquids, etc., can solve the problem that the dispersion degree of magnetic nanoparticles is not significantly improved, and achieve excellent superparamagnetic performance, good elasticity, and avoid agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] According to another aspect of the present invention, the present invention also provides a method for preparing the above-mentioned ethylene glycol-based magnetic fluid composite membrane, comprising the following steps:

[0043] (a) mixing ethylene glycol, a dispersion stabilizer and nano ferric oxide, and dispersing evenly to obtain an ethylene glycol-based magnetic fluid;

[0044] (b) dissolving polyvinyl alcohol in deionized water, then adding ethylene glycol-based magnetic fluid, uniformly dispersed, and then coating a film to obtain an ethylene glycol-based magnetic fluid composite film.

[0045] The preparation method of the ethylene glycol-based magnetic fluid composite membrane provided by the invention has the advantages of safe and convenient operation, mild reaction conditions, and does not require harsh equipment conditions, so that it can be used in industrialized production.

[0046] In a preferred embodiment of the present invention, in step (a), disper...

Embodiment 1

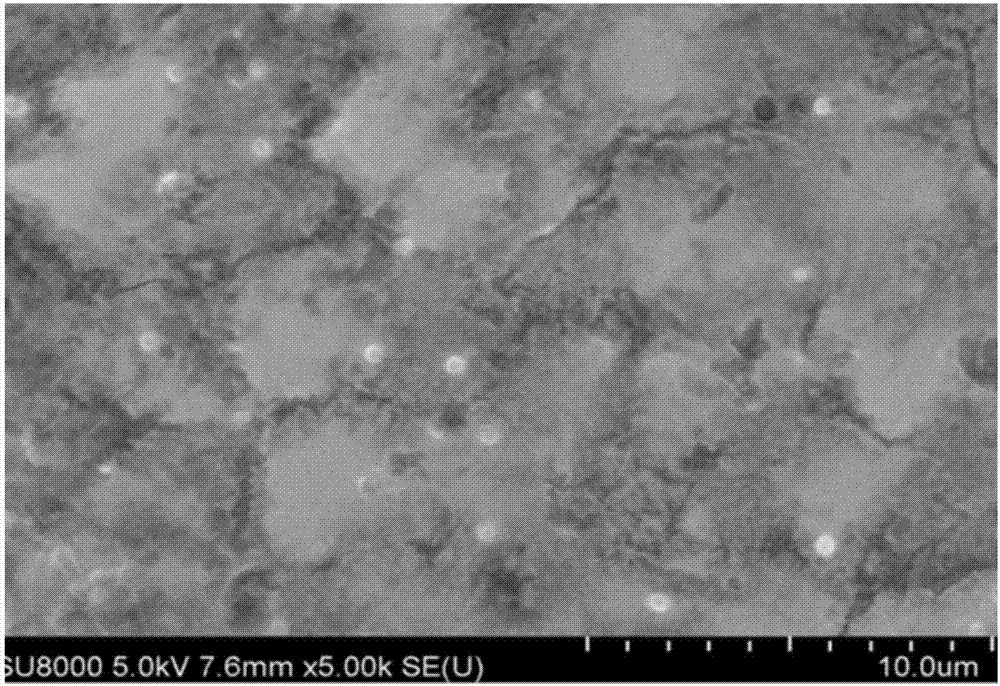

[0064] This embodiment provides an ethylene glycol-based magnetic fluid composite film, which is prepared from the following components in parts by mass: 90 parts of ethylene glycol-based magnetic fluid, 25 parts of polyvinyl alcohol, and 85 parts of deionized water , wherein the ethylene glycol-based magnetic fluid is prepared from the following components in parts by mass: 25 parts of nano-ferric oxide, 40 parts of ethylene glycol, 35 parts of a dispersion stabilizer, and the dispersion stabilizer is citric acid.

Embodiment 2

[0066] This embodiment provides an ethylene glycol-based magnetic fluid composite film, which is prepared from the following components in parts by mass: 110 parts of ethylene glycol-based magnetic fluid, 20 parts of polyvinyl alcohol, and 70 parts of deionized water , wherein the ethylene glycol-based magnetic fluid is prepared from the following components in parts by mass: 35 parts of nanometer ferric oxide, 30 parts of ethylene glycol, 35 parts of a dispersion stabilizer, and the dispersion stabilizer is sodium citrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com