Hybridization seed production method capable of improving purity and germination rate of wax gourd seeds

A technology for hybrid seed production and wax gourd, which is applied in the fields of seed and rhizome treatment, botanical equipment and methods, human or animal body preservation, etc. , Conducive to the normal development of flower organs and the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0048] The steps of the seed production method in the facility net room described in Embodiment 2 of the present invention:

[0049] 1) Immerse wax gourd seeds in ramie fiber hydrolyzate and hops fermented product at 42-48°C, and treat them with an ultrasonic device with an ultrasonic frequency of 26KHz for 10-15 seconds;

[0050] The specific production method of the hop fermentation product is as follows: fresh hops are crushed into a slurry, inoculated with yeast, fermented at 32-35°C for 26-28 hours, after high-temperature sterilization, dried until the water content is lower than 8%, and the hops fermented thing.

[0051] 2)-10) steps are the same as 1)-9) steps of Example 1.

Embodiment 3

[0052] The steps of the seed production method in the facility net room described in Embodiment 3 of the present invention:

[0053] 1) Immerse wax gourd seeds in ramie fiber hydrolyzate and hops fermented product at 42-48°C, and treat them with an ultrasonic device with an ultrasonic frequency of 26KHz for 10-15 seconds;

[0054] The specific production method of the hop fermentation product is as follows: fresh hops are crushed into a slurry, inoculated with yeast, fermented at 32-35°C for 26-28 hours, after high-temperature sterilization, dried until the water content is lower than 8%, and the hops fermented thing. The concentration of chalcones in the hop fermented product aqueous solution was 15%.

[0055] 2)-10) steps are the same as 1)-9) steps of Example 1.

[0056] The steps of the seed production method in the facility net room described in Embodiment 4 of the present invention:

[0057] The steps are the same as in Example 3, wherein the concentration of chalcone...

Embodiment 5

[0058] The steps of the seed production method in the facility net room described in Embodiment 5 of the present invention:

[0059] The steps are the same as in Example 3, wherein the concentration of chalcones in the hop fermented product aqueous solution is 13%.

[0060] The steps of the seed production method in the facility net room described in Embodiment 6 of the present invention:

[0061] The steps are the same as in Example 3, wherein the concentration of chalcones in the hop fermented product aqueous solution is 20%.

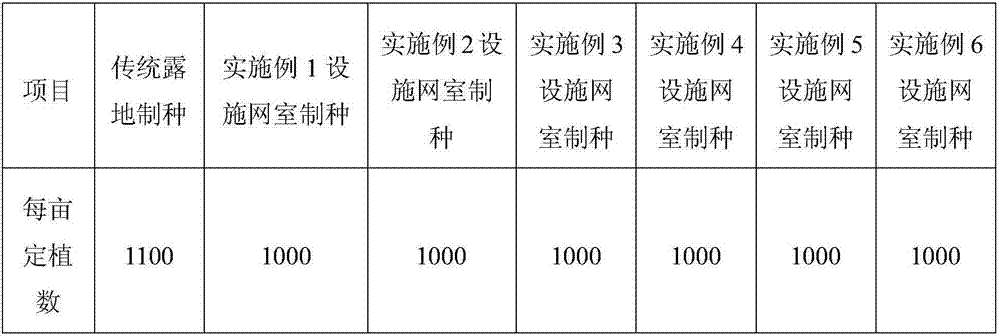

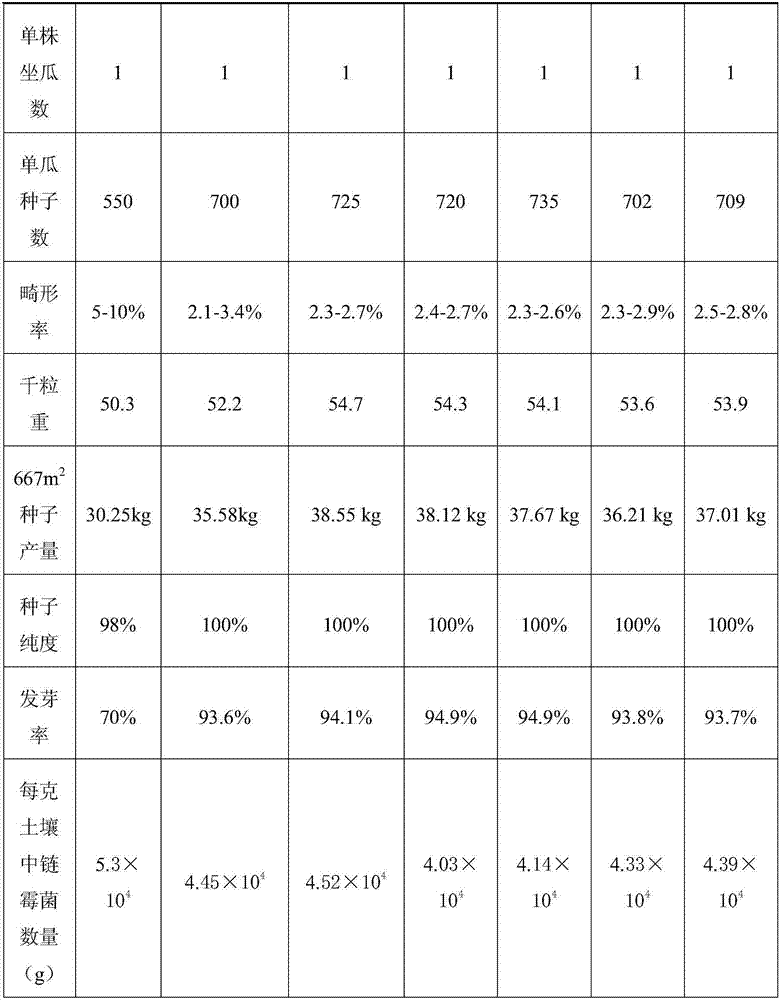

[0062] The wax gourd seeds that above each embodiment makes all test on a plurality of standard test fields, and the value in the table below is the average value of a plurality of standard test field tests, and the deformity rate is the upper and lower extreme value range after getting rid of the error value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com