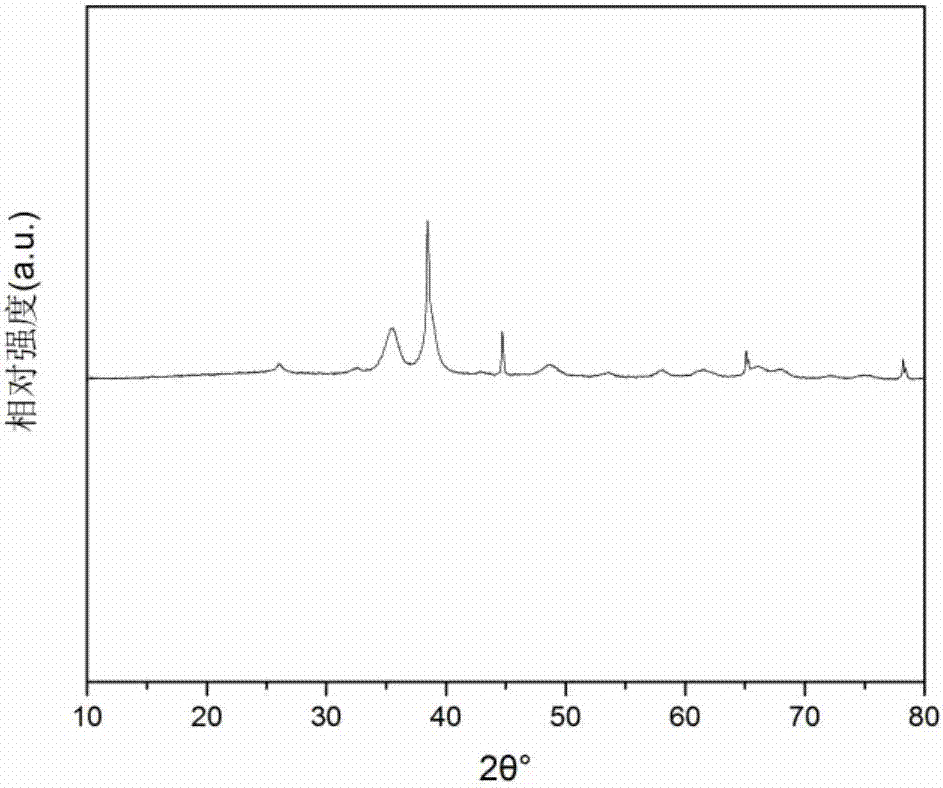

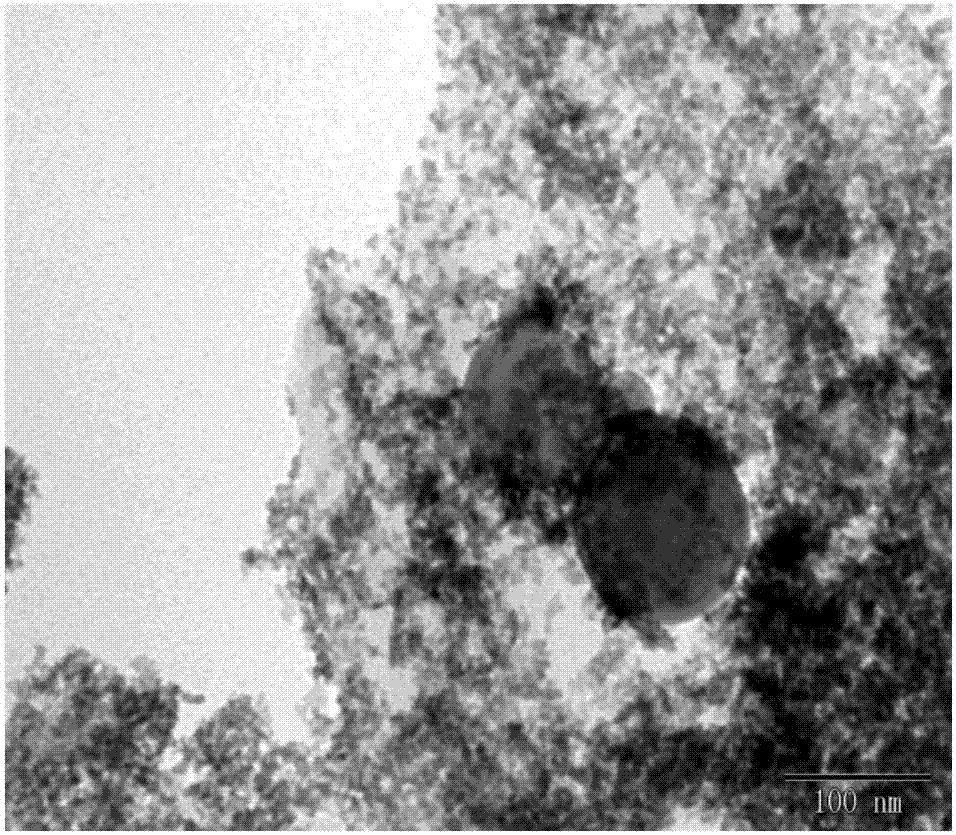

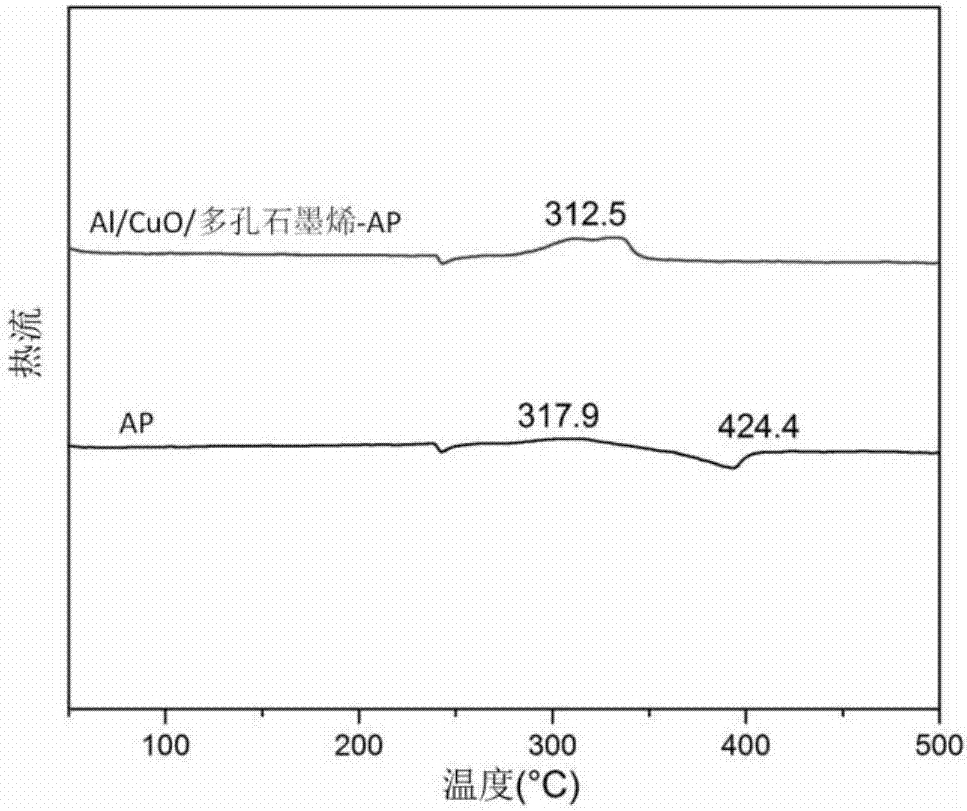

Al/CuO/porous graphene nano-composite energetic material and preparation method thereof

A nano-composite material, porous graphene technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, attack equipment, etc., can solve the problem of uneven particle size of the composite, low product purity, It is easy to introduce impurities and other problems to achieve the effect of increasing density and surface active sites, high product purity, and accelerating combustion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The specific steps for the preparation of an Al / CuO / porous graphene nanocomposite energetic material are as follows:

[0038] (1) Preparation of porous graphene

[0039] Add 1.14 mmol ammonium molybdate to 50 mL of graphene oxide aqueous dispersion with a concentration of 4 mg / mL, ultrasonically disperse for 30 min, continue mechanical stirring for 9 h, and then freeze-dry; place the freeze-dried mixture in a tube furnace, Heat to 650°C at a heating rate of 10°C / min, keep it warm for 2 hours, and then cool to room temperature under the protection of nitrogen; immerse the product obtained after heat treatment in 1mol / L HCl aqueous solution, and stir mechanically for 7 days to remove the metal in the product oxide, and then filtered, washed with water, washed with alcohol, and dried in vacuum to obtain porous graphene;

[0040] (2) Preparation of CuO / porous graphene nanocomposites

[0041]Take 10 mg of the porous graphene prepared in step (1) and add it to a mixed solut...

Embodiment 2

[0048] The specific steps for the preparation of an Al / CuO / porous graphene nanocomposite energetic material are as follows:

[0049] (1) Preparation of porous graphene

[0050] Add 1.2mmol ammonium molybdate to 50mL graphene oxide aqueous dispersion with a concentration of 3.5mg / mL, ultrasonically disperse for 1h, continue mechanical stirring for 10h, and freeze-dry; place the freeze-dried mixture in a tube furnace , heated to 600°C at a heating rate of 8°C / min, kept warm for 2.2h, and then cooled to room temperature under the protection of nitrogen; the product obtained after heat treatment was immersed in 0.8mol / L HCl aqueous solution, and mechanically stirred for 7d to remove the product The metal oxide in the mixture is filtered, washed with water, washed with alcohol, and dried in vacuum to obtain porous graphene;

[0051] (2) Preparation of CuO / porous graphene nanocomposites

[0052] Take 8 mg of the porous graphene prepared in step (1) and add it to a mixed aqueous so...

Embodiment 3

[0059] The specific steps for the preparation of an Al / CuO / porous graphene nanocomposite energetic material are as follows:

[0060] (1) Preparation of porous graphene

[0061] Add 1.5mmol ammonium molybdate to 50mL graphene oxide aqueous dispersion with a concentration of 4.5mg / mL, ultrasonically disperse for 50min, continue to stir for 12h, and then freeze-dry; place the freeze-dried mixture in a tube furnace, Heat to 620°C at a heating rate of 12°C / min, keep it warm for 2.1h, then cool to room temperature under the protection of nitrogen; immerse the product obtained after heat treatment in 1.2mol / L HCl aqueous solution, stir mechanically for 6d, and remove the product The metal oxide, then filtered, washed with water, washed with alcohol, vacuum dried, porous graphene;

[0062] (2) Preparation of CuO / porous graphene nanocomposites

[0063] Take 12 mg of the porous graphene prepared in step (1) and add it to a mixed solution consisting of 300 mL of 0.03 mol / L copper nitra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com