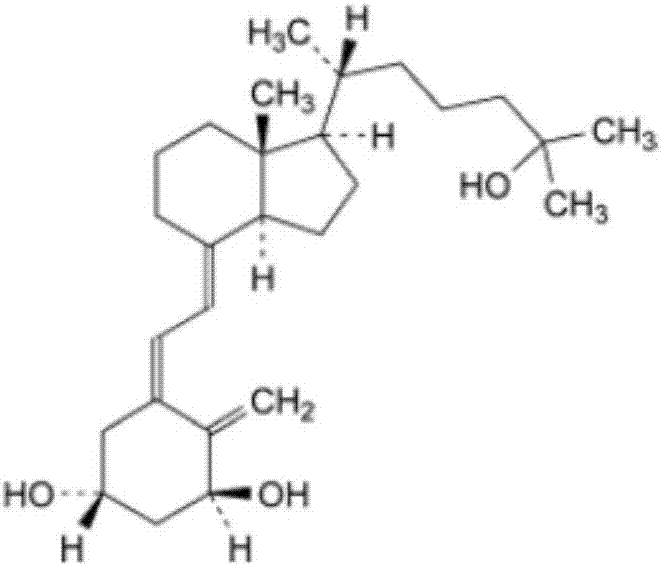

Calcitriol liquid hard capsule, method for preparing same and application of calcitriol liquid hard capsule

A liquid hard capsule, calcitriol technology, which is applied in the directions of capsule delivery, bone diseases, pharmaceutical formulations, etc., can solve problems such as poor solubility, and achieve the effects of simple method, excellent solubility and stability, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

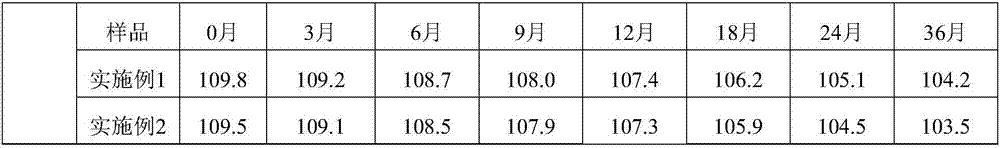

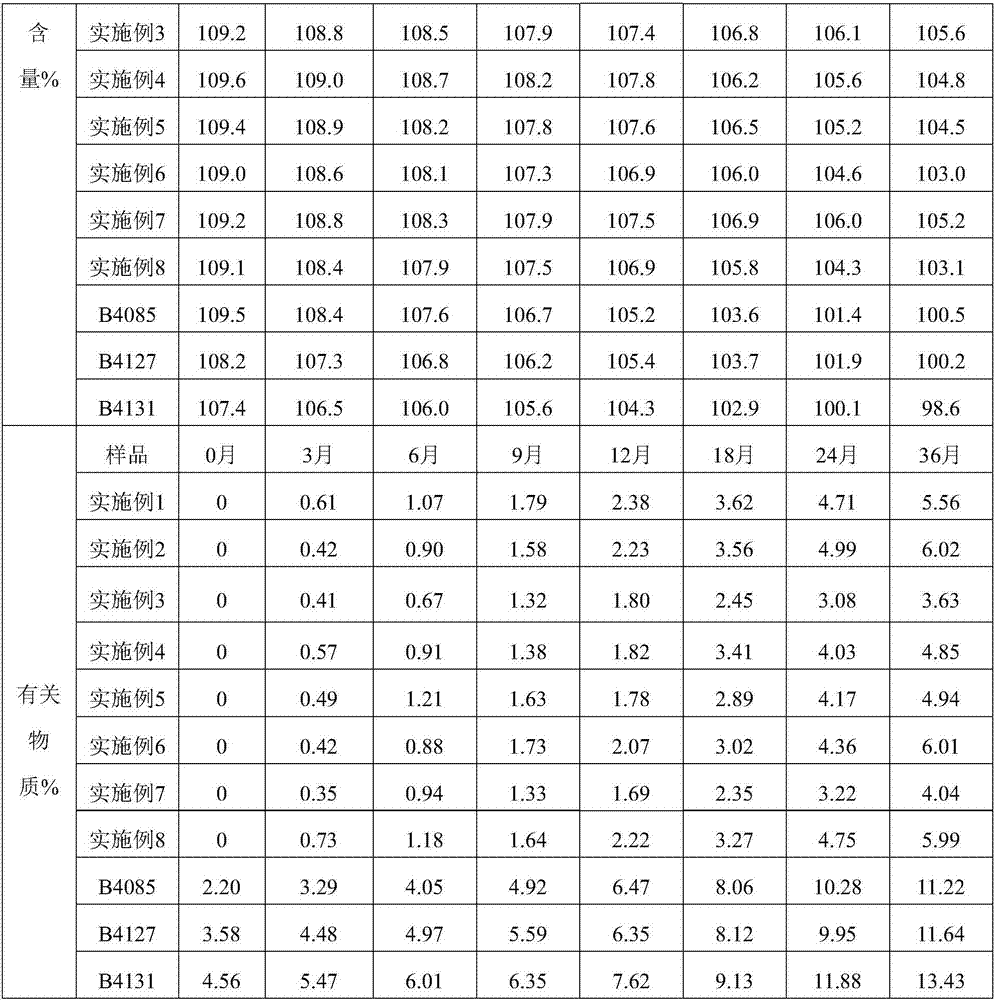

Examples

Embodiment 1

[0039] The preparation method of calcitriol liquid hard capsule is as follows:

[0040] 1) Ingredients: 0.25mg of calcitriol, 160g of medium-chain fatty acid triglyceride, 16mg of dibutylhydroxytoluene, 16mg of butylhydroxyanisole, 1000 gelatin capsules;

[0041] 2) Stir and dissolve medium-chain fatty acid triglycerides, dibutyl hydroxytoluene, and butyl hydroxyanisole in a stirring tank for 20 minutes, then add calcitriol and continue stirring for 120 minutes until the dissolution is complete, vacuumize and degas, and pour it into a hard In the capsule shell, and encapsulate the pharmaceutical coating material at the capsule's sleeve.

Embodiment 2

[0043] The preparation method of calcitriol liquid hard capsule is as follows:

[0044] 1) Ingredients: 0.5mg calcitriol, 170g coconut oil, 15mg dibutylhydroxytoluene, 15mg butylhydroxyanisole, 1000 gelatin capsules;

[0045] 2) After stirring and dissolving coconut oil, dibutyl hydroxytoluene and butyl hydroxyanisole in a stirring tank, add calcitriol and continue stirring to dissolve completely, vacuumize and degas, infuse in the hard capsule shell, and place in the capsule The sheathing part of the bag is encapsulated with a medicinal coating material.

Embodiment 3

[0047] The preparation method of calcitriol liquid hard capsule is as follows:

[0048] 1) Ingredients: 0.25mg calcitriol, 150g castor oil, 17.5mg dibutylhydroxytoluene, 17.5mg butylhydroxyanisole, 1000 HPMC hollow capsules;

[0049] 2) After stirring and dissolving castor oil, dibutyl hydroxytoluene and butyl hydroxyanisole in a stirring tank for 30 minutes, add calcitriol and continue stirring for 100 minutes until the dissolution is complete, vacuumize and degas, pour into the hard capsule shell, And encapsulate the medicinal coating material at the joint of the capsule.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com