High transmittance and high solubility macromolecular dye, color photosensitive resin composition and color filter

A technology of macromolecular dyes and photosensitive resins, applied in the field of color filters, can solve problems such as dye intensification, chromaticity change, and dye volatilization, and achieve high brightness and contrast, good environmental tolerance, and color fastness low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

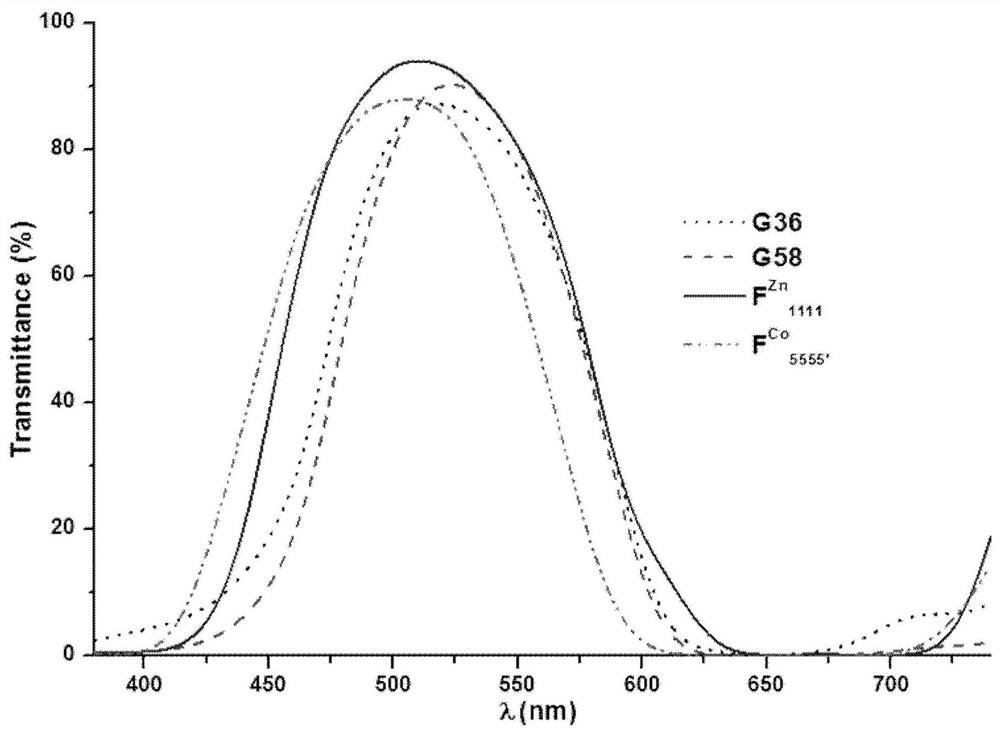

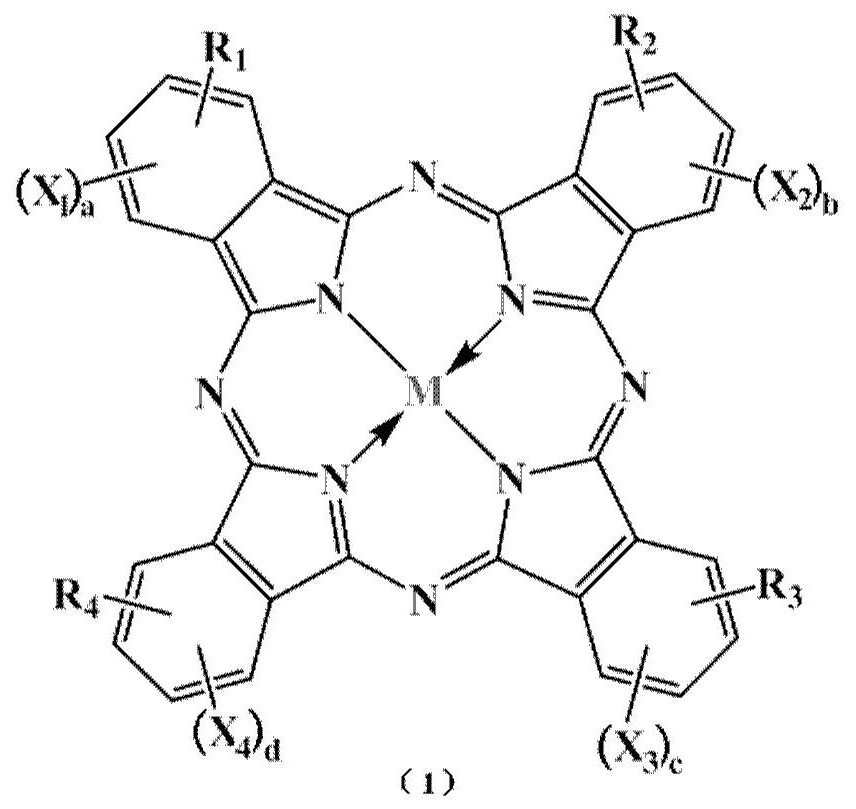

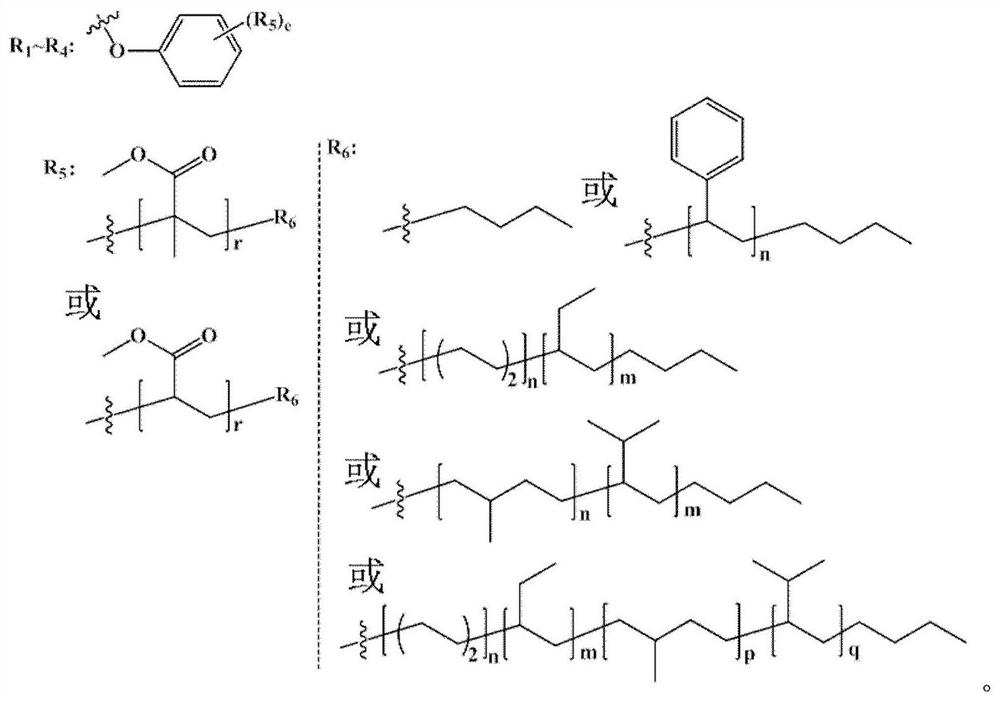

[0157] Example 1-1 Macromolecular phthalocyanine dye F Zn 1111 Synthesis

[0158]

[0159] Under the protection of argon, add 4-(4-polystyrene-b-polymethylmethacrylate-phenoxy)-3,5,6-trichlorophthalonitrile F- 1 (1.0eq), DBU (2.0eq) and n-butanol, start stirring and heat up, add anhydrous zinc acetate (0.25eq) after the raw materials are fully dissolved, and heat to reflux. After the reaction is finished, the solvent is drained, purified with a flash chromatography column (PE: EA=29: 1), and vacuum-dried to obtain the macromolecular phthalocyanine dye F zn 1111 . Molecular weight M w =9200, PDI=1.10.

Embodiment 1-2

[0160] Example 1-2 Macromolecular phthalocyanine dye F Co 5555’ Synthesis

[0161]

[0162] Under the protection of argon, add 4-(4-polyacrylate-phenoxy)-3,5,6-trichlorophthalonitrile F-5 (0.8eq) into the three-necked flask, 4- (4-polyacrylate-phenoxy)-3,5,6-trichlorophthalonitrile F-5' (0.25eq), DBU (2.0eq) and n-butanol, start stirring and heat up, After the raw materials were fully dissolved, anhydrous cobalt acetate (0.25eq) was added and heated to reflux. After the reaction is finished, the solvent is drained, purified with a flash chromatography column (PE: EA=25: 1), and vacuum-dried to obtain the macromolecular phthalocyanine dye F Co 5555’ . Molecular weight M w =8400, PDI=1.09.

[0163] Comparative Example 1-1 Pigment Dispersion Liquid G36

[0164] CAS registration number: 14302-13-7, purchased from DIC Corporation, the specific structure is as follows:

[0165]

Embodiment 2-1

[0169] The preparation of embodiment 2-1 green photosensitive resin composition E1

[0170] Utilize the macromolecular phthalocyanine dye F prepared by above-mentioned embodiment 1-1 Zn 1111 , formulated into a colored photosensitive resin composition E1, and subjected to photolithographic development to compare the relative properties of the photosensitive resin composition. In particular, lithographic imaging methods well known to those skilled in the art are applied.

[0171] Prescription: get 200 parts by weight coloring agent L (by F Zn 1111 and solvent Q1), 50 parts by weight of multifunctional monomer M1, 50 parts by weight of multifunctional monomer M2, 100 parts by weight of alkali-soluble resin N, 0.2 parts by weight of additive O1, 0.3 parts by weight of O2, 5 parts by weight of photoinitiator P, add about 100 parts by weight of solvent Q1 and about 50 parts by weight of solvent Q2 to fully dissolve and mix, control the solid content at about 20%, and obtain a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com