A method of improving feed maturation

A feed and material technology, applied in the fields of feed, food science, application, etc., can solve the problems of uncertainty of feed conditioning time and temperature, material cannot be fully matured, affecting feed safety, etc. Avoid mutual interference and facilitate the effect of mixing evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

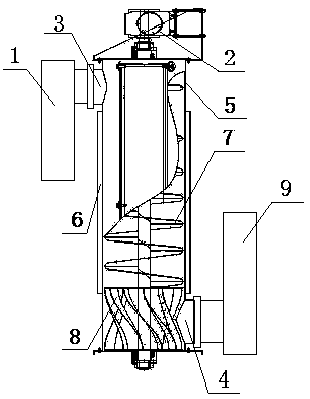

[0041] like figure 1 As shown, a method for improving feed maturation, comprising the following steps:

[0042] X1: The material prepared by the computer is sent into the feeder 1 for stirring;

[0043] X2: Input steam into the casing 5 through several steam inlets 6;

[0044] X3: The material that has completed the first step is transported into the shell 5 through the feeder 1, and the material is quenched, tempered and mixed by the screw stirring and transporting 7;

[0045] X4: Send the material after the third step of quenching and tempering to a granulator for granulation;

[0046] The steps of the conditioning and mixing treatment in the X3 step are:

[0047] S1: Pressurize the shell 5, and keep the pressure between 506.625-810.6 kPa;

[0048] S2: heat and keep the clinker in the shell 5, the temperature is controlled at 150-180°C, the moisture content of steam conditioning is 22-32%, and the conditioning time is 6-10min;

[0049] S3: Supplement water vapor to the ...

Embodiment 2

[0056] like figure 1 As shown, a method for improving feed maturation, comprising the following steps:

[0057] X1: The material prepared by the computer is sent into the feeder 1 for stirring;

[0058] X2: Input steam into the casing 5 through several steam inlets 6;

[0059] X3: The material that has completed the first step is transported into the shell 5 through the feeder 1, and the material is quenched, tempered and mixed by the screw stirring and transporting 7;

[0060] X4: Send the material after the third step of quenching and tempering to a granulator for granulation;

[0061] The steps of the conditioning and mixing treatment in the X3 step are:

[0062] S1: Pressurize the shell 5, and keep the pressure between 506.6256 kPa;

[0063] S2: heat and keep the clinker in the shell 5, the temperature is controlled at 150 ° C, the moisture content of steam conditioning is 22%, and the conditioning time is 6 minutes;

[0064] S3: Supplement water vapor to the clinker ...

Embodiment 3

[0077] like figure 1 As shown, a method for improving feed maturation, comprising the following steps:

[0078] X1: The material prepared by the computer is sent into the feeder 1 for stirring;

[0079] X2: Input steam into the casing 5 through several steam inlets 6;

[0080] X3: The material that has completed the first step is transported into the shell 5 through the feeder 1, and the material is quenched, tempered and mixed by the screw stirring and transporting 7;

[0081] X4: Send the material after the third step of quenching and tempering to a granulator for granulation;

[0082] The steps of the conditioning and mixing treatment in the X3 step are:

[0083] S1: Pressurize the shell 5, and keep the pressure between 810.6 kPa;

[0084] S2: heat and keep the clinker in the shell 5, the temperature is controlled at 180°C, the moisture content of steam conditioning is 32%, and the conditioning time is 10min;

[0085] S3: Supplement water vapor to the clinker in the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com