Fixed carrier membrane with slice screening channel and preparation method and application thereof

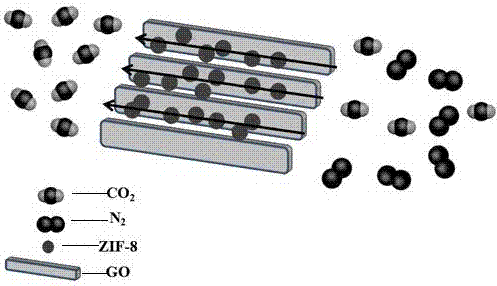

A fixed carrier and screening technology, which is applied in separation methods, chemical instruments and methods, membranes, etc., can solve problems such as pipeline corrosion and reduce the calorific value of natural gas, and achieve the effects of simple process, high CO2 permeation rate and separation factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of the immobilized carrier membrane of in-situ loading zeolite imidazolate framework material on the surface of aminated graphene oxide, the steps are as follows:

[0035] Step 1, prepare 1mg / mL graphene oxide dispersion liquid by Hummers method;

[0036] Step 2, followed by in-situ synthesis of ZIF-8 and the amine group modification of graphene oxide in the above-mentioned graphene oxide dispersion, the specific method is: in the dispersion of graphene oxide with a solid content of 10 mg, add 367 mg of hexahydrate Zinc nitrate, ultrasonically mixed for 0.25-2 hours until the solution is uniform, named solution A; 708mg of 2-methylimidazole and 0.5mL ethylenediamine were added to deionized water, magnetically stirred for 2-6 hours until uniformly mixed, named solution B; quickly add solution B to solution A, stir magnetically at 25°C for 24 hours, centrifuge at 5000-20000 rpm for 10-30 minutes, remove supernatant, wash with water 3 times to remove unreac...

Embodiment 2

[0040] Embodiment 2: the preparation of the immobilized carrier film of loading zeolite imidazolate framework material in situ on the surface of aminated graphene oxide, the steps are as follows:

[0041] Step 1, prepare 1 mg / mL graphene oxide dispersion by Hummers method; (same as Example 1)

[0042] Step 2, followed by in-situ synthesis of ZIF-8 and the amine group modification of graphene oxide in the above-mentioned graphene oxide dispersion, the specific method is: in the dispersion of graphene oxide with a solid content of 10 mg, add 367 mg of hexahydrate Zinc nitrate, ultrasonically mixed for 0.25-2 hours until the solution is uniform, named solution A; 708mg of 2-methylimidazole and 0.5mL ethylenediamine were added to deionized water, magnetically stirred for 2-6 hours until uniformly mixed, named solution B; quickly add solution B to solution A, stir magnetically at 25°C for 24 hours, centrifuge at 5000-20000 rpm for 10-30 minutes, remove supernatant, wash with water ...

Embodiment 3

[0046] Embodiment 3: the preparation of the immobilized carrier film of loading zeolite imidazolate framework material in situ on the surface of aminated graphene oxide, the steps are as follows:

[0047] Step 1, prepare 1 mg / mL graphene oxide dispersion by Hummers method; (same as Example 1)

[0048] Step 2, followed by in-situ synthesis of ZIF-8 and the amine group modification of graphene oxide in the above-mentioned graphene oxide dispersion, the specific method is: in the dispersion of graphene oxide with a solid content of 10 mg, add 367 mg of hexahydrate Zinc nitrate, ultrasonically mixed for 0.25-2 hours until the solution is uniform, named solution A; 708mg of 2-methylimidazole and 0.5mL ethylenediamine were added to deionized water, magnetically stirred for 2-6 hours until uniformly mixed, named solution B; quickly add solution B to solution A, stir magnetically at 25°C for 24 hours, centrifuge at 5000-20000 rpm for 10-30 minutes, remove supernatant, wash with water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com