A kind of preparation method of formaldehyde degradable ag/zno composite material

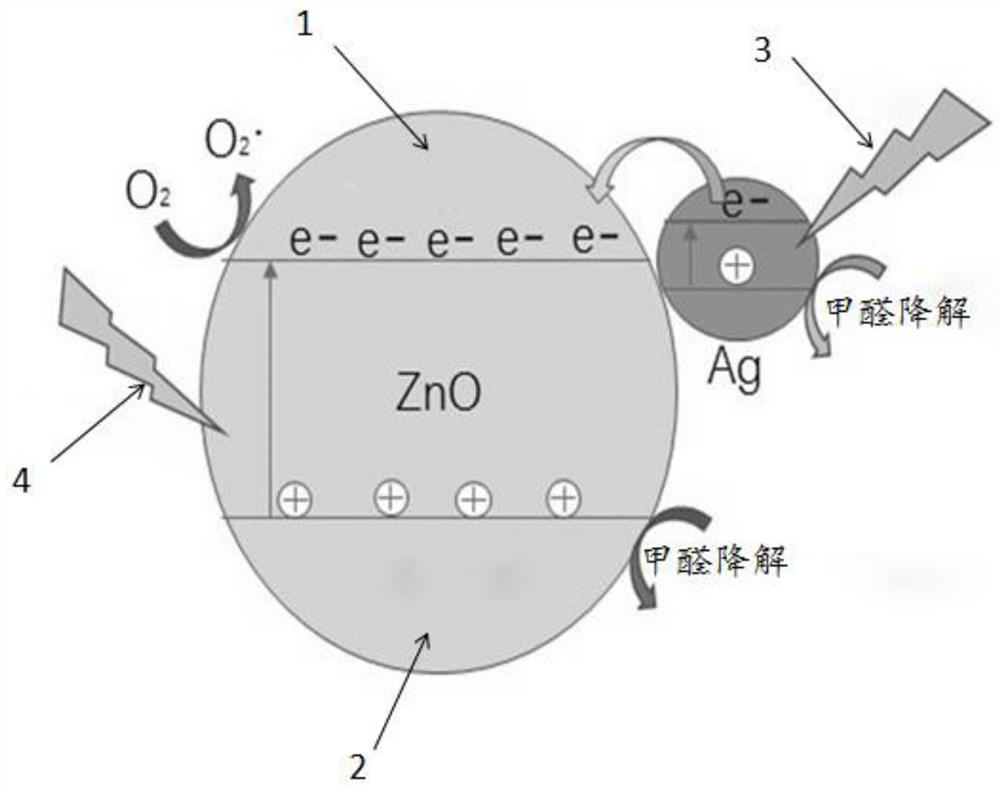

A composite material and formaldehyde technology, applied in the field of photocatalyst preparation, to achieve the effect of improving charge separation, photocatalytic effect and photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method of preparing an Ag / ZnO composite material that degrates formaldehyde, including the following steps:

[0031] (1) Nano ZnO particles were prepared: 50 mL of 1 mol / lzn (NO3) 2 solution was added to a 200 ml of beaker, and 50 ml of 2 mol / l NaOH solution was added while stirring. Stay for a day. The resulting precipitate was filtered, washed, and dried in an oven at 80 ° C. The dry precipitate was placed in a muffle furnace for 3 h. The ZnO nanoparticles can be obtained after cooling.

[0032] (2) Preparation of Ag / ZnO: Ag nanoparticle is uniformly dispersed by physical vapor deposition on the ZnO nanoparticles made of step (1), forming Ag / ZnO composite nanoparticles, physical vapor deposition, first vacuum 0.05 ppa, and maintain a vacuum no less than 0.1 Pa, ZnO and Ag mass ratio of 20: 1.

[0033] The Ag / ZnO complex nanoparticles prepared by the present embodiment were placed in the reactor, and the test of formaldehyde treatment was performed. As a resu...

Embodiment 2

[0036] A method of preparing an Ag / ZnO composite material that degrates formaldehyde, including the following steps:

[0037] (1) Nano ZnO particles were prepared: 50 mL of 1 mol / lzn (NO3) 2 solution was added to a 200 ml of beaker, and 50 ml of 2 mol / l NaOH solution was added while stirring. Stay for a day. The resulting precipitate was filtered, washed, and dried in an oven at 80 ° C. The dry precipitate was placed in a muffle furnace for 3 h. The ZnO nanoparticles can be obtained after cooling.

[0038](2) Preparation of Ag / ZnO: Ag nanoparticle is uniformly dispersed by physical vapor deposition on the ZnO nanoparticles made of step (1), forming Ag / ZnO composite nanoparticles, physical vapor deposition, first vacuum 0.05 ppa, and maintain a vacuum no less than 0.1 Pa, ZnO and Ag mass ratio 20: 1;

[0039] (3) Ag / ZnO complex nanoparticles prepared by step (2) and mixed with coconut shell and polyethylene, wherein Ag / ZnO complex nanoparticles, coconut reactive carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com