Graphene-porous nickel oxide composite catalyst for advanced treatment of waste water, preparation method and application

A composite catalyst and advanced treatment technology, which is applied in the field of water treatment, can solve the problems of low efficiency and low catalytic activity in sewage treatment, and achieve the effects of less energy consumption, obvious COD removal effect and excellent dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

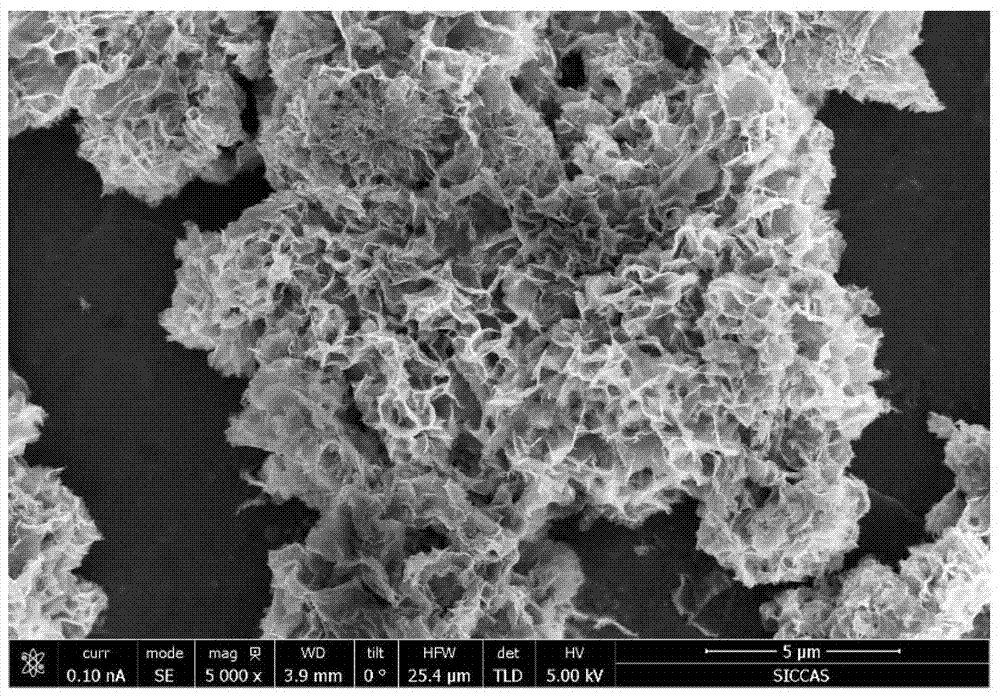

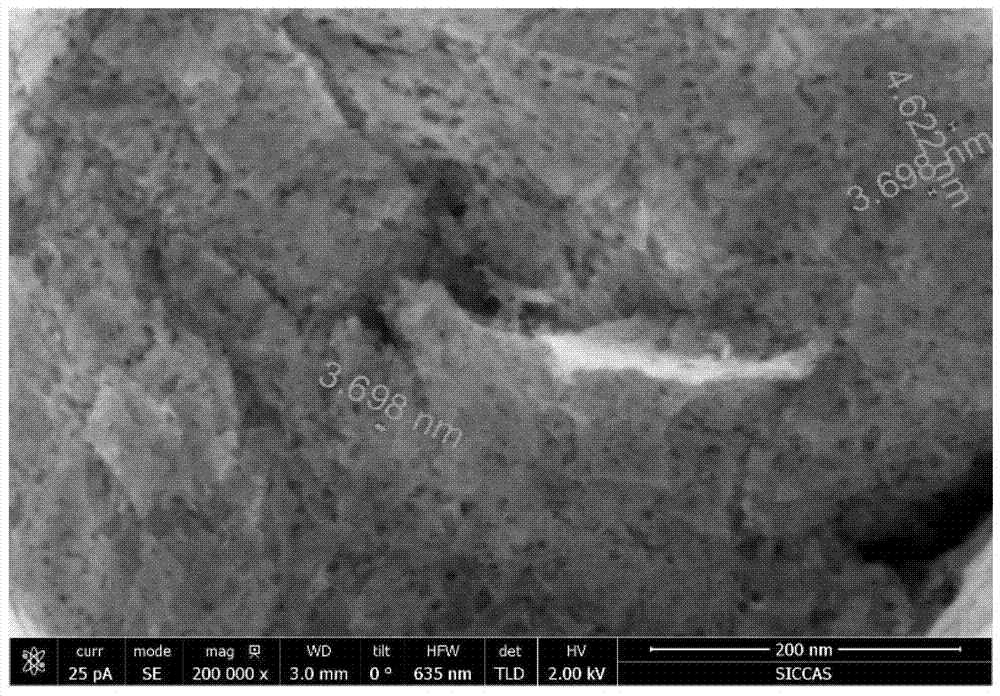

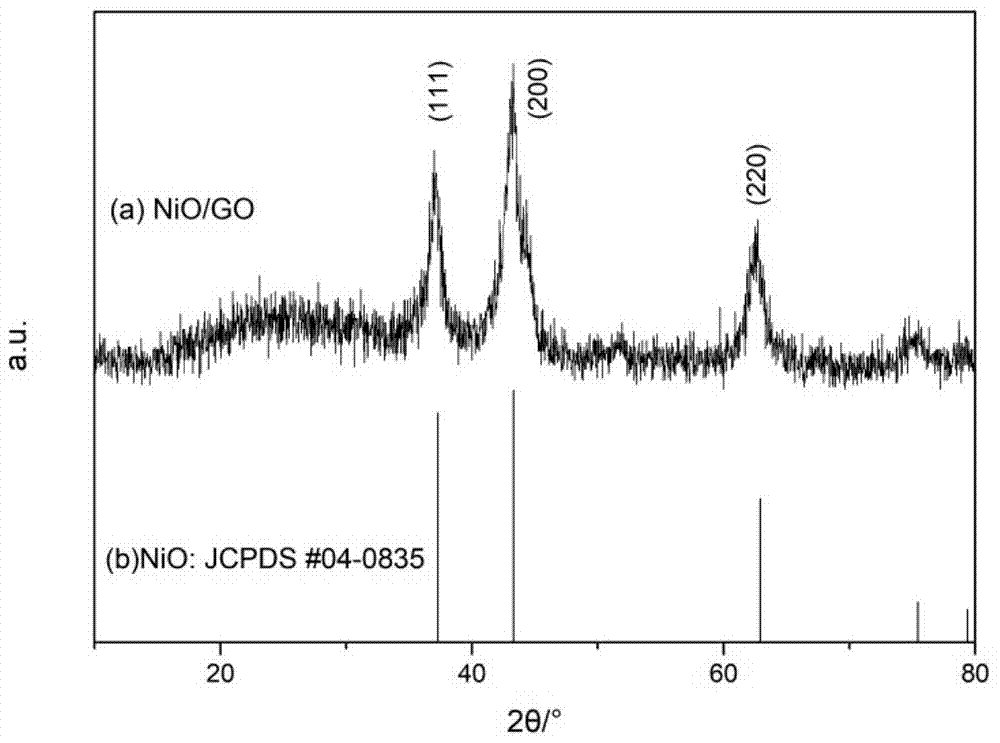

[0044] Weigh 1.45g of nickel nitrate hexahydrate and 0.3g of urea, add 25ml of ethylene glycol, and sonicate for 30min to fully dissolve the solid drug in the solvent. Pipette 5ml of a well-dispersed 20mg / ml graphene oxide (GO) aqueous solution and add it to the above solution, and ultrasonicate for 30min to disperse the graphene oxide evenly. Then the mixed solution was transferred into a 50ml polytetrafluoroethylene-lined stainless steel hydrothermal kettle, and reacted at 180°C for 10h to obtain a catalyst precursor. The obtained product was washed three times with water and three times with alcohol, then suction filtered and dried in an oven at 50°C for 12 hours. The dried precursor was annealed in a box furnace at 350° C. for 2 h to obtain a graphene-nickel oxide composite catalyst A, and the mass ratio of the graphene carrier to porous nickel oxide was 1:3. mentioned. figure 1 The SEM photo of the prepared graphene-nickel oxide composite catalyst shows that the catalys...

Embodiment 2

[0048] Weigh 2.90 g of nickel nitrate hexahydrate and 0.6 g of urea, add 25 ml of ethylene glycol, and sonicate for 30 minutes to fully dissolve the solid drug in the solvent. Pipette 5ml of a well-dispersed 20mg / ml graphene oxide (GO) aqueous solution and add it to the above solution, and ultrasonicate for 30min to disperse the graphene oxide evenly. Then the mixed solution was transferred into a 50ml polytetrafluoroethylene-lined stainless steel hydrothermal kettle, and reacted at 180°C for 10h to obtain a catalyst precursor. The obtained product was washed three times with water and three times with alcohol, then suction filtered and dried in an oven at 50°C for 12 hours. The dried precursor was annealed in a box furnace at 350° C. for 2 h to obtain a graphene-nickel oxide composite catalyst, and the mass ratio of the graphene carrier to porous nickel oxide was 1:6. Figure 5 This is the SEM photo of the prepared graphene-nickel oxide composite catalyst. The catalyst is co...

Embodiment 3

[0052]Weigh 0.725 g of nickel nitrate hexahydrate and 0.15 g of urea, add 25 ml of ethylene glycol, and sonicate for 30 minutes to fully dissolve the solid drug in the solvent. Pipette 5ml of a well-dispersed 20mg / ml graphene oxide (GO) aqueous solution and add it to the above solution, and ultrasonicate for 30min to disperse the graphene oxide evenly. Then the mixed solution was transferred into a 50ml polytetrafluoroethylene-lined stainless steel hydrothermal kettle, and reacted at 180°C for 10h to obtain a catalyst precursor. The obtained product was washed three times with water and three times with alcohol, then suction filtered and dried in an oven at 50°C for 12 hours. The dried precursor was annealed in a box furnace at 350° C. for 2 h to obtain a graphene-nickel oxide composite catalyst, and the mass ratio of the graphene carrier to porous nickel oxide was 2:3.

[0053] Add 0.2 g of the above catalyst powder into 100 ml of methylene blue aqueous solution with a conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com