Method for effectively regulating particle size of ceric oxide mesoporous sphere and application thereof

A technology of ceria and mesoporous spheres, applied in chemical instruments and methods, rare earth metal oxides/hydroxides, inorganic chemistry, etc., can solve the problem of expensive surfactants, inducers, stabilizers or templates, difficult The scale control of ceria mesoporous materials, unfavorable large-scale production and application, etc., achieve the effect of simple and easy follow-up processing, good monodispersity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

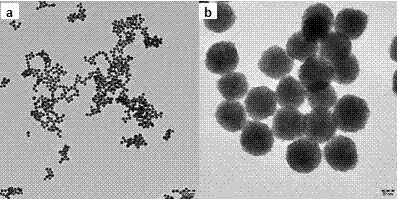

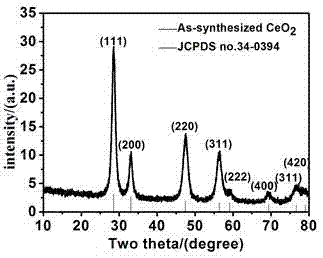

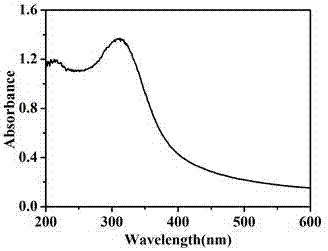

[0023] Preparation of 30nm CeO2 Mesoporous Spheres

[0024] Under stirring conditions, 2.1 milliliters of deionized water were added to 67.9 milliliters of ethylene glycol solution, stirred evenly to obtain a water-containing ethylene glycol solution, then 1.52 g of cerium nitrate hexahydrate was added, and stirred for 30 minutes at 500 rpm to make Cerium nitrate was completely dissolved to obtain a reaction precursor solution for preparing cerium oxide mesoporous spheres, wherein the concentration of cerium nitrate was 0.05 mol / liter, and the volume percentage of water content was 3%. Immediately afterwards, the prepared reaction precursor solution was reacted in an oil bath at 180 degrees for 1 hour to obtain a colloidal solution of ceria mesoporous spheres; After centrifuging at a speed of 14,000 rpm for 30 minutes, remove the colorless solution in the centrifuge tube to obtain a yellow precipitate product; use deionized water or absolute alcohol to ultrasonically clean the...

Embodiment 2

[0026] Preparation of 50nm CeO2 Mesoporous Spheres

[0027] Under stirring conditions, 2.8 milliliters of deionized water were added to 67.2 milliliters of ethylene glycol solution, stirred evenly to obtain aqueous ethylene glycol solution, then added 1.52 g of cerium nitrate hexahydrate, and stirred for 30 minutes at 500 rpm to make Cerium nitrate was completely dissolved to obtain a reaction precursor solution for preparing cerium oxide mesoporous spheres, wherein the concentration of cerium nitrate was 0.05 mol / liter, and the volume percentage of water content was 4%. Immediately afterwards, the prepared reaction precursor solution was reacted in a 180-degree oil bath for 2 hours to obtain a colloidal solution of ceria mesoporous spheres; After centrifuging at 12,000 rpm for 30 minutes, remove the colorless solution in the centrifuge tube to obtain a yellow precipitated product; use deionized water or absolute alcohol to ultrasonically clean the obtained precipitated produc...

Embodiment 3

[0029] Preparation of 100nm CeO2 Mesoporous Spheres

[0030]Under agitation, add 3.5 milliliters of deionized water to 66.5 milliliters of ethylene glycol solution, stir evenly to obtain a water-containing ethylene glycol solution, then add 1.52 g of cerium nitrate hexahydrate, and stir for 30 minutes at 500 rpm to make Cerium nitrate was completely dissolved to obtain a reaction precursor solution for preparing cerium oxide mesoporous spheres, wherein the concentration of cerium nitrate was 0.05 mol / liter, and the volume percentage of water content was 5%. Immediately afterwards, the prepared reaction precursor solution was reacted in a 180-degree oil bath for 4 hours to obtain a colloidal solution of ceria mesoporous spheres; After centrifuging at 10,000 rpm for 30 minutes, remove the colorless solution in the centrifuge tube to obtain a yellow precipitate product; use deionized water or absolute alcohol to ultrasonically clean the obtained precipitate product 5-6 times, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com