Method for slowing membrane pollution in membrane capacitance deionization system

A membrane capacitive deionization and membrane fouling technology, which is applied in separation methods, chemical instruments and methods, water/sewage treatment, etc., can solve problems such as membrane fouling, clogging, and membrane performance deterioration, so as to overcome serious membrane fouling and improve desalination Efficiency, the effect of inhibiting the growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

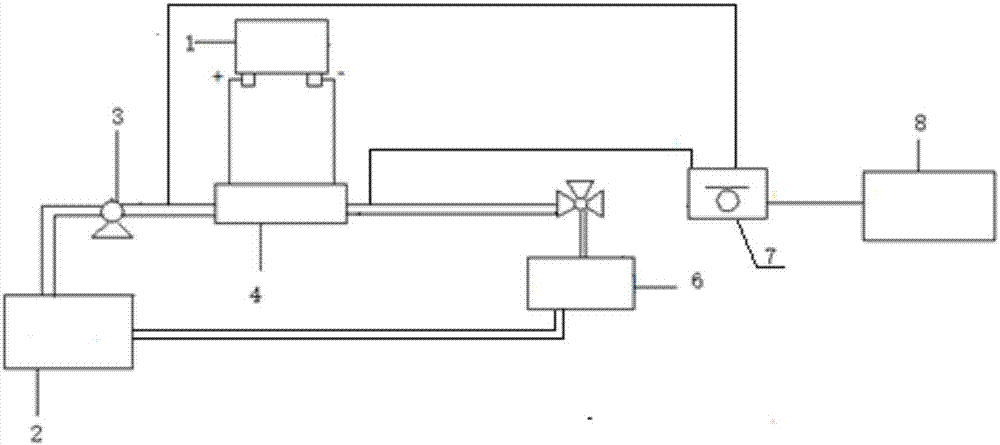

Image

Examples

Embodiment 1

[0022] The influent water contains microbial carriers, and the microbial carriers are loaded with facultative anaerobic microorganisms. The concentration of fixed microorganisms on the microbial carriers is 15g / L (dry weight). The influent also contains bovine albumin (BSA), ammonium chloride, Calcium chloride and sodium chloride, the concentration of ammonium chloride is 4mg / L, the concentration of calcium chloride is 180mg / L, the concentration of sodium chloride is 140mg / L, the concentration of BSA is 40mg / L, and the concentration of EDTA is 50mg / L. The initial conductivity of the influent water is maintained at 800 μS / cm; the influent water enters the membrane capacitor module under the action of the water pump for desalination treatment, and the DC power supply provides a stable voltage, and the voltage is maintained at 1.2V; after 55 minutes of desalination treatment, the electrode adsorption reaches saturation, and the effluent The conductivity is stable at 480μS / cm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com