Exterior wall insulation waterproof crack-resistant putty powder

A technology of anti-cracking putty and external wall insulation, applied in the direction of filling slurry, etc., can solve the problems of insufficient waterproof performance, crack resistance and thermal insulation performance, inability to play auxiliary heat insulation, and inability to meet market demand, etc., to achieve Increase whiteness and anti-freeze performance and anti-carbonization performance, improve sterilization and anti-corrosion performance, and long-term scraping time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

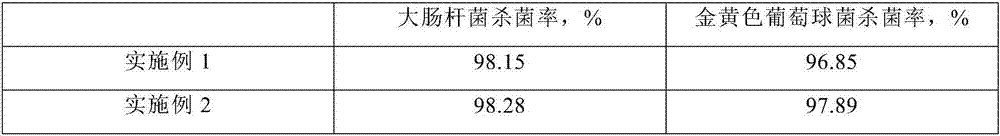

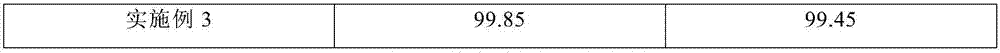

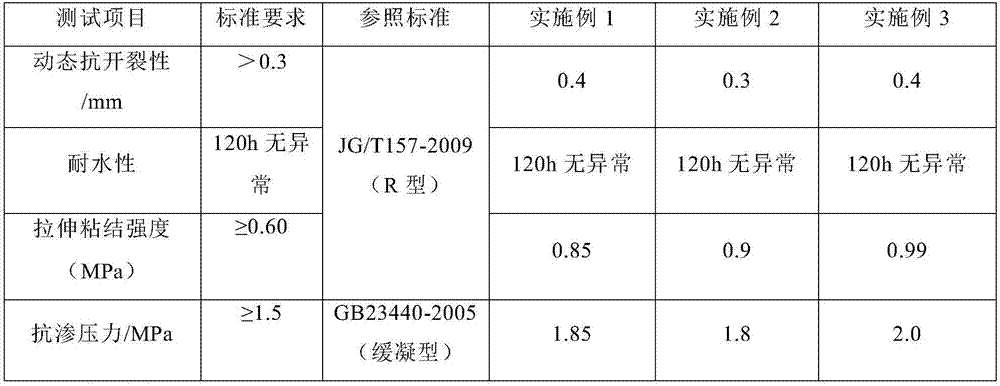

Embodiment 1

[0025] The invention relates to an external wall thermal insulation, waterproof and anti-cracking putty powder. The preparation method of the ultraviolet absorber is to mix extracts of polygonatum polygonatum and sophora japonica.

[0026] The preparation method of the polygonatum polygonatum and pagoda japonica mixed extract is as follows: drying equal weight polygonatum polygonatum and pagoda japonica to constant weight, crushing them through 40 meshes, adding 70% ethanol to the polygonatum polygonatum and pagoda japonica mixed powder, and ultrasonically extracting at 60°C 20min, ultrasonically filtered and ultrasonically extracted twice, and the two filtrates were combined to obtain the product.

[0027] In the method for preparing the mixed extract of Polygonatum polygonatum and Sophora japonica, the solid-to-liquid ratio of Polygonatum polygonatum and Sophora japonica mixed powder to ethanol is 1:20.

[0028] In the method for preparing the mixed extract of polygonatum po...

Embodiment 2

[0032] The invention relates to an external wall thermal insulation, waterproof and anti-cracking putty powder. The preparation method of the ultraviolet absorber is to mix extracts of polygonatum polygonatum and sophora japonica.

[0033] The preparation method of the polygonatum polygonatum and pagoda japonica mixed extract is as follows: drying equal weight polygonatum polygonatum and pagoda japonica to constant weight, crushing them through 40 meshes, adding 70% ethanol to the polygonatum polygonatum and pagoda japonica mixed powder, and ultrasonically extracting at 60°C 30min, ultrasonically filtered and ultrasonically extracted twice, and the two filtrates were combined to obtain the product.

[0034] In the method for preparing the mixed extract of Polygonatum Polygonatum and Sophora japonica, the solid-liquid ratio of Polygonatum polygonatum and Sophora japonica mixed powder to ethanol is 1:30.

[0035] In the method for preparing the mixed extract of polygonatum polyg...

Embodiment 3

[0039] The invention relates to an external wall thermal insulation, waterproof and anti-cracking putty powder. The preparation method of the ultraviolet absorber is to mix extracts of polygonatum polygonatum and sophora japonica.

[0040] The preparation method of the polygonatum polygonatum and pagoda japonica mixed extract is as follows: drying equal weight polygonatum polygonatum and pagoda japonica to constant weight, crushing them through 40 meshes, adding 70% ethanol to the polygonatum polygonatum and pagoda japonica mixed powder, and ultrasonically extracting at 60°C 25min, ultrasonically filtered and ultrasonically extracted twice, and the two filtrates were combined to obtain the product.

[0041] In the method for preparing the mixed extract of Polygonatum Polygonatum and Sophora japonica, the solid-liquid ratio of Polygonatum polygonatum and Sophora japonica mixed powder to ethanol is 1:25.

[0042] In the method for preparing the mixed extract of polygonatum polyg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com