Preparing method and application of corrosion inhibitor restraining carbon steel acid corrosion

A corrosion inhibitor and carbon steel technology, applied in the field of imidazoline corrosion inhibitors, can solve the problems of being unable to meet the requirements of corrosion inhibition in strong acid environments, poor water solubility of corrosion inhibitors, etc., and achieve the effects of easy promotion, low toxicity, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

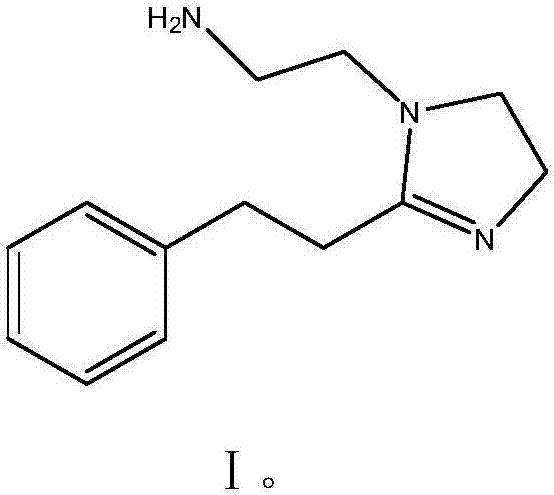

[0033] The preparation method of phenylpropyl imidazoline:

[0034] Mix 15g of 3-phenylpropionic acid, 15mL of diethylenetriamine, and 7mL of xylene, stir magnetically and start heating; heat up to 170°C for amidation reaction for 5 hours, then heat up to 220°C for cyclization React for 3 hours; after the reaction is completed, transfer it to a rotary evaporator for vacuum distillation to evaporate excess diethylenetriamine and xylene, then place it in a vacuum drying oven to dry at room temperature, and finally obtain dark brown viscous styrene-acrylic acid imidazoline derivatives.

[0035] The invention uses quantum chemical calculation to study the adsorption performance of phenylpropyl imidazoline and uses a weight loss method to test the corrosion inhibition performance of phenylpropyl imidazoline in acidic environment. Quantum chemical calculations were used to study the adsorption properties of different imidazoline molecules; the weight loss experiment was carried out...

Embodiment 1

[0037] Quantum chemistry calculations:

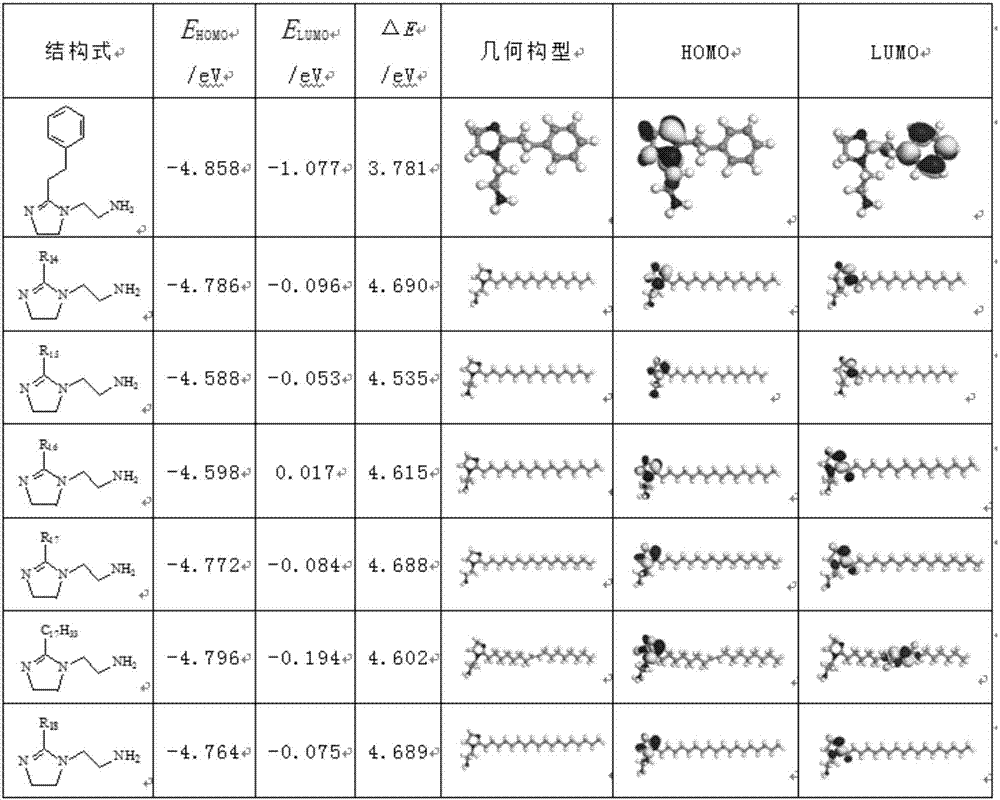

[0038] The seven kinds of imidazoline molecules obtained by the reaction of carboxylic acids such as 3-phenylpropanoic acid, pentadecanoic acid, palmitic acid, heptadecanoic acid, stearic acid, oleic acid and nonadecanoic acid with diethylenetriamine were calculated respectively. The energy of the frontier orbit, the result is as follows figure 1 shown.

[0039] The ΔE of phenylpropylimidazoline obtained from 3-phenylpropionic acid and diethylenetriamine is significantly smaller than that of other imidazoline molecules, so the adsorption performance is the best.

Embodiment 2

[0041] The preparation method of phenylpropyl imidazoline:

[0042] Mix 15g of 3-phenylpropionic acid, 15mL of diethylenetriamine, and 7mL of xylene, stir magnetically and start heating; heat up to 170°C for amidation reaction for 5 hours, then heat up to 220°C for cyclization React for 3 hours; after the reaction is completed, transfer it to a rotary evaporator for vacuum distillation to evaporate excess diethylenetriamine and xylene, then place it in a vacuum drying oven to dry at room temperature, and finally obtain dark brown viscous styrene-acrylic acid Based imidazoline derivatives, the yield of the product can reach 85.1%.

[0043] The infrared spectrogram data of product are as follows:

[0044] 3287cm -1 It is the stretching vibration peak of -N-H, 3026cm -1 The =C-H stretching vibration peak of the benzene ring appeared at 1604cm -1 The -C=N double bond absorption peak is the characteristic absorption peak of imidazoline at 1650cm -1 and 1555cm -1The absorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com