Resin concrete-based mechanical part and preparation method thereof

A technology for resin concrete and mechanical parts, applied in the field of machine tool parts, can solve the problems of prolonged production cycle, complicated equipment installation and debugging, large thermal expansion coefficient of metal materials, etc., to improve impact toughness and split resistance, and easy installation and debugging process. Easy to do, effect of high heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] The preparation method of the above-mentioned resin concrete-based mechanical parts includes the following steps:

[0056] S1. Weigh seven kinds of granite or marble particles according to the proportion by weight, mix them evenly and dry the moisture, and use them as aggregate for later use;

[0057] S2. Weigh fly ash, quartz powder, talc powder, granite powder or marble powder according to the proportion of parts by weight, and use them as fillers for later use;

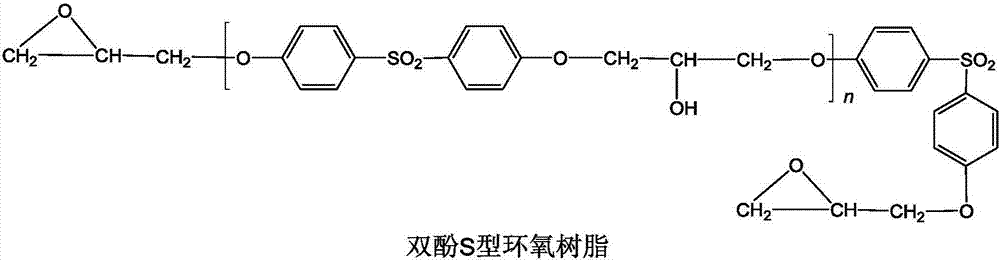

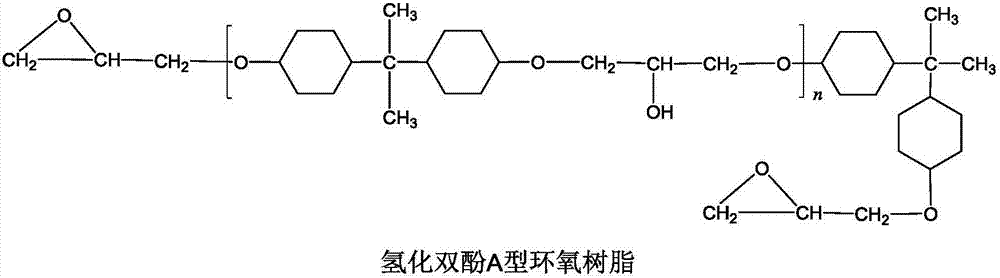

[0058] S3. Weigh bisphenol S type epoxy resin, hydrogenated bisphenol A type epoxy resin and alicyclic epoxy resin according to the proportion of parts by weight, stir evenly at room temperature, and use it as the epoxy resin component for later use;

[0059] S4. Weigh the aliphatic polyamine curing agent, tertiary amine curing agent and imidazole curing agent according to the proportion by weight, stir evenly at room temperature, and use it as the curing agent component for later use;

[0060] S5. Mix the epoxy resin...

Embodiment 1

[0065] Example 1: Preparation of mechanical parts based on resin concrete.

[0066] Prepare materials according to the following table:

[0067]

[0068] Preparation:

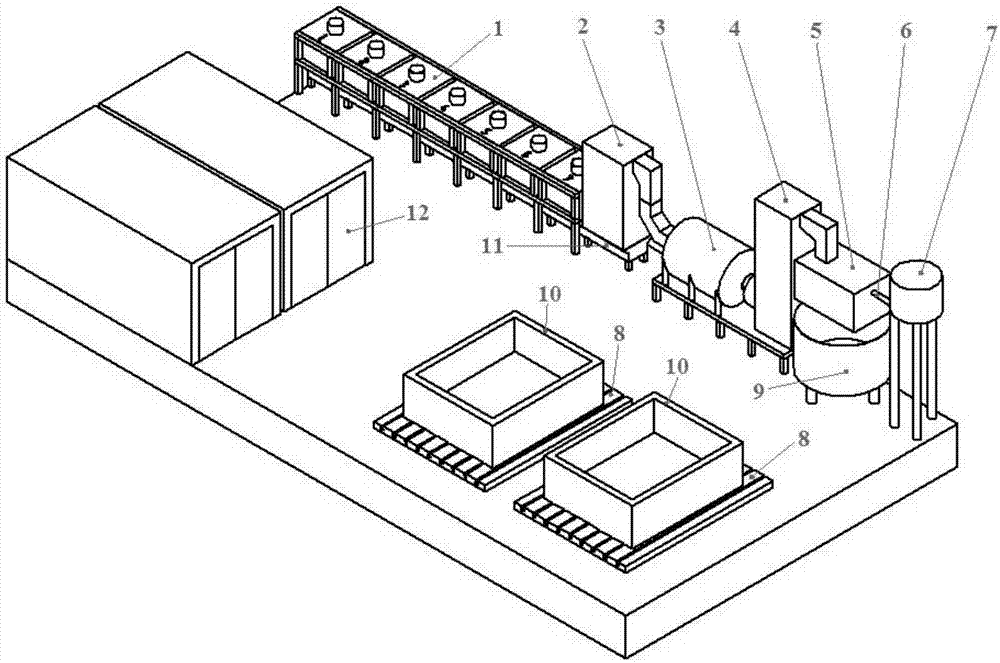

[0069] S1. Put seven kinds of granite particles with different sizes in seven hoppers 1, and weigh them by the precision electronic scale in hopper 1 according to the dosage in the above table. After weighing, the seven kinds of particles will fall into The mixing conveyor belt 11 is transported to the mixing box 2 for mixing. The uniformly stirred mixture is transported to the drying box 3 for drying, and the dried mixture is transported to the aggregate storage box. 4, as an aggregate spare;

[0070] S2. Weigh fly ash according to the amount in the above table and use it as a filler for later use;

[0071] S3. Weigh bisphenol S type epoxy resin, hydrogenated bisphenol A type epoxy resin and bis(2,3-epoxycyclopentyl) ether according to the amount in the above table, and stir it evenly at room temperature as epoxy resi...

Embodiment 2

[0076] Example 2: Preparation of mechanical parts based on resin concrete.

[0077] Prepare materials according to the following table:

[0078]

[0079] Preparation:

[0080] S1. Put seven kinds of granite particles with different sizes in seven hoppers 1, and weigh them by the precision electronic scale in hopper 1 according to the dosage in the above table. After weighing, the seven kinds of particles will fall into The mixing conveyor belt 11 is transported to the mixing box 2 for mixing. The uniformly stirred mixture is transported to the drying box 3 for drying, and the dried mixture is transported to the aggregate storage box. 4, as an aggregate spare;

[0081] S2. Weigh talcum powder according to the amount in the above table, as a filler for later use;

[0082] S3. Weigh bisphenol S type epoxy resin, hydrogenated bisphenol A type epoxy resin and 2,3-epoxycyclopentylcyclopentyl ether according to the amount in the above table, and stir it evenly at room temperature as epoxy re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com