Low temperature pyrolysis method for low-rank coal with small particle size

A low-temperature pyrolysis, low-rank coal technology, applied in the field of coal chemical industry, can solve the problems of difficult separation of fine coal powder and coal tar mixture, no industrial application performance, easy to block equipment pipelines, etc., so as to improve the comprehensive efficiency of enterprises and market competition. power, reducing the amount of pyrolysis wastewater, and the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

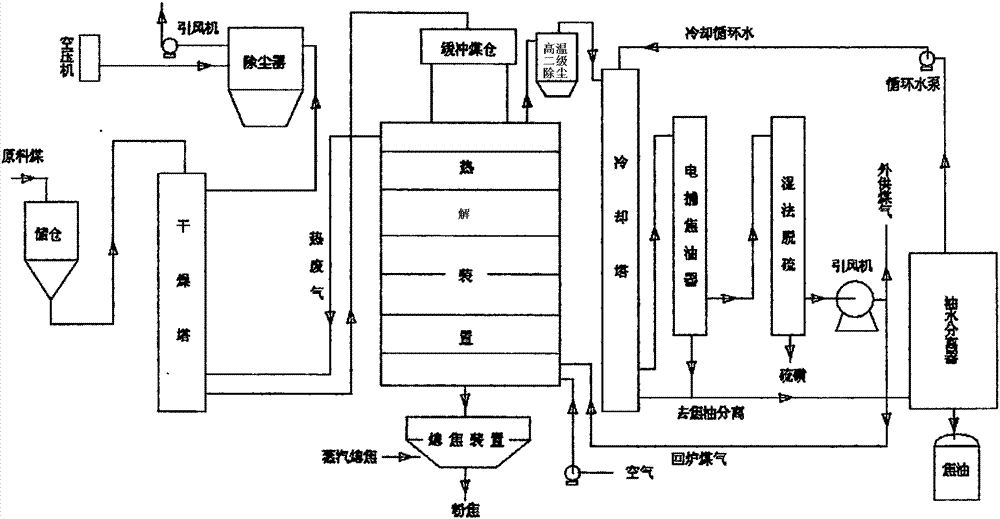

[0027] Such as Figure 1-Figure 3 As shown, a kind of low-rank pulverized coal low-temperature pyrolysis method provided by the present invention mainly includes the following process steps:

[0028] Step 1. Firstly, the raw coal is fed into the dryer from the storage bin through the elevator for preheating and drying. Specifically, the raw coal is transported from the coal storage yard to the storage bin through the belt, and then sent into the drying tower through the bucket elevator. In the drying tower, the pulverized coal moves from top to bottom relying on its own weight, and goes countercurrently with the hot flue gas to exchange heat directly. When the temperature rises to 120°C and the moisture drops below 0.5%, the drying process is completed and discharged from the outlet at the bottom of the tower. The hot flue gas discharged from the pyrolysis furnace is introduced into the bottom of the drying tower through the flue. Under the action of the bottom of the tower a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com