Water-soluble external composition with fullerene

An external composition, fullerene technology, applied in the field of daily chemicals, to achieve the effect of stable properties, easy absorption and utilization, and easy efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

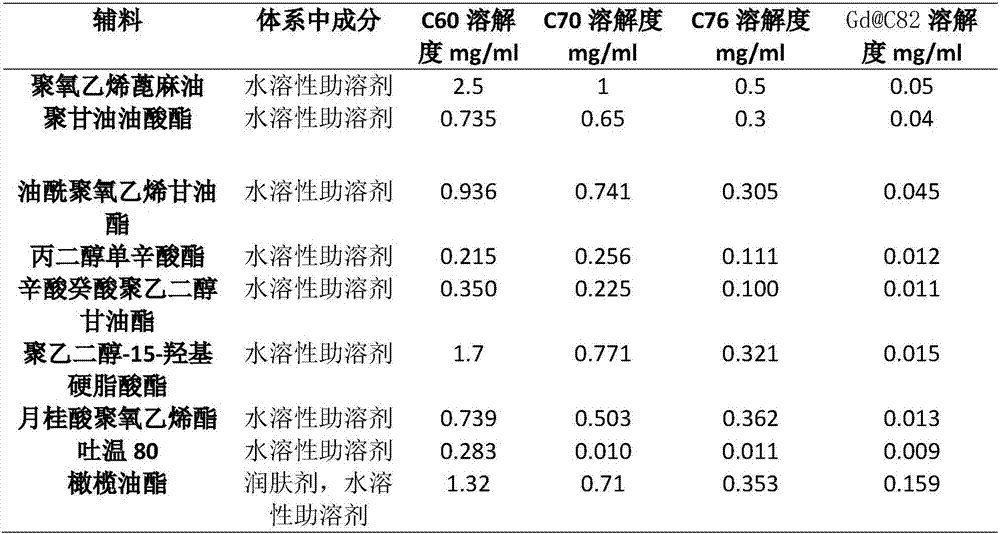

[0072] 15-hydroxystearic acid polyethylene glycol ester, caprylic capric acid polyethylene glycol glyceride, polyoxyethylene castor oil, olive oil ester in a weight ratio of 2:2:5:1-fullerene (QXBG-C60 ).

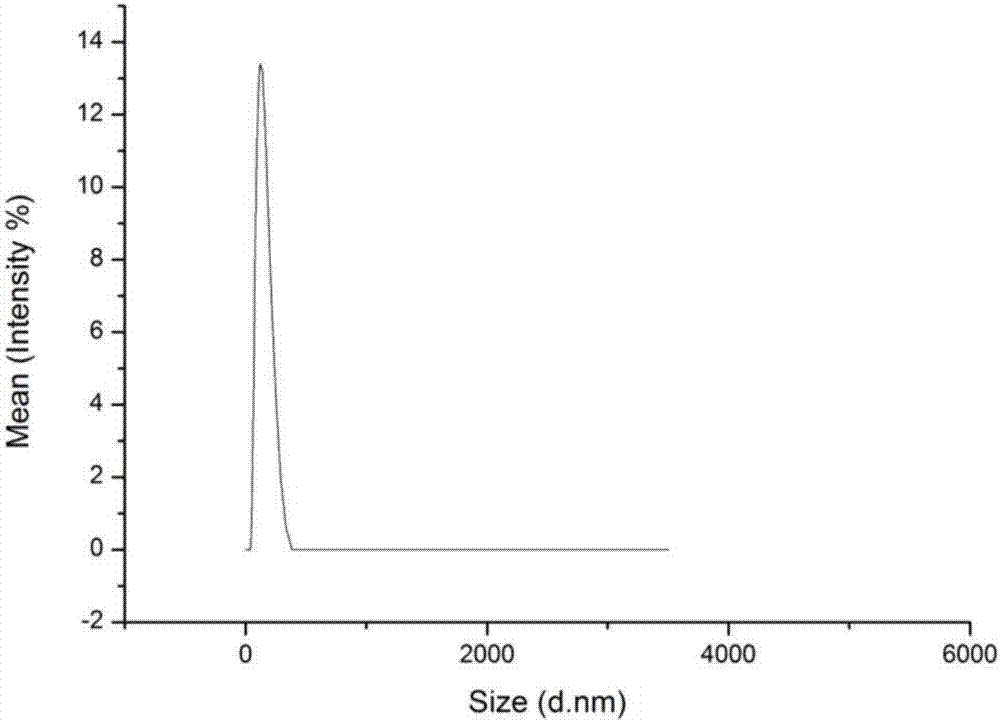

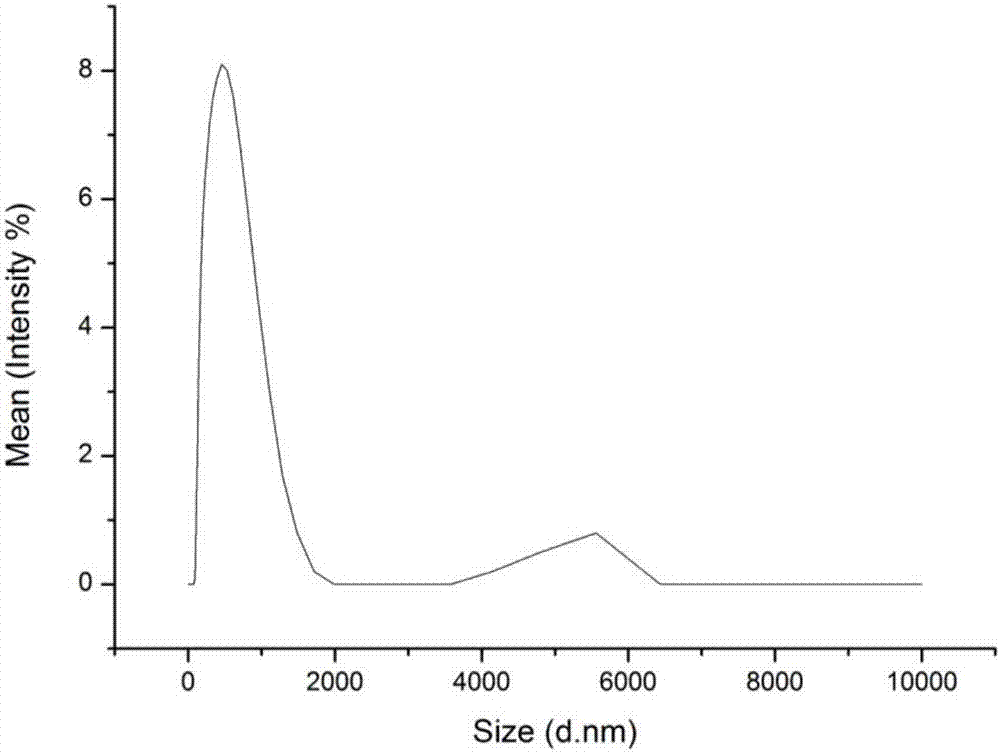

[0073] Firstly, polyethylene glycol 15-hydroxystearate, polyethylene glycol caprylate caprylate, polyoxyethylene castor oil, and olive oil ester were uniformly mixed in proportion to obtain a mixture solvent with a volume of 1 L. Then take 4g of fullerene C60, disperse in the mixed solvent, put the mixture of the two in the ball mill, 700 rpm, the temperature of the ball mill tank is controlled between 20-30 degrees, take it out after ball milling for 7h, put the mixture in Put it in the container, heat the container, control the temperature at 40-50 degrees, turn on the built-in stirring paddle in the container, and continue to stir for 72 hours, then take out the solution, centrifuge and filter to obtain QXBG-FULLERENE, use the fullerene C60 standard curve to calibrate to...

Embodiment 2

[0075] 15-hydroxystearic acid polyethylene glycol ester, caprylic capric acid polyethylene glycol glyceride, polyoxyethylene castor oil, olive oil ester in a weight ratio of 2:2:5:1-fullerene (QXBG-C70 ).

[0076] Firstly, polyethylene glycol 15-hydroxystearate, polyethylene glycol caprylate caprylate, polyoxyethylene castor oil, and olive oil ester were uniformly mixed in proportion to obtain a mixture solvent with a volume of 1 L. Then take 3g of fullerene C70, disperse in the mixed solvent, place the mixture of the two in the ball mill, 700 rpm, the temperature of the ball mill tank is controlled between 20-30 degrees, take it out after ball milling for 7h, and place the mixture Put it in the container, heat the container, control the temperature at 35-45 degrees, turn on the built-in stirring paddle in the container, continue to stir for 72 hours, then take out the solution, centrifuge and filter to obtain QXBG-FULLERENE, use the fullerene C70 standard curve to calibrate t...

Embodiment 3

[0078]15-hydroxystearic acid polyethylene glycol ester, caprylic capric acid polyethylene glycol glyceride, polyoxyethylene castor oil, olive oil ester in a weight ratio of 2:2:5:1-fullerene (QXBG-C76 ).

[0079] Firstly, polyethylene glycol 15-hydroxystearate, polyethylene glycol caprylate caprylate, polyoxyethylene castor oil, and olive oil ester were uniformly mixed in proportion to obtain a mixture solvent with a volume of 1 L. Then take 1g of fullerene C76, disperse it in the mixed solvent, place the mixture of the two in a ball mill, 800 rpm, control the temperature of the ball mill tank between 20-30 degrees, take it out after 7 hours of ball milling, and place the mixture Put it in the container, heat the container, control the temperature at 30-40 degrees, turn on the built-in stirring paddle in the container, continue to stir for 72 hours, then take out the solution, centrifuge and filter to obtain QXBG-FULLERENE, use the fullerene C76 standard curve to calibrate to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com