Dry method automobile acoustic absorption roof and preparation method thereof

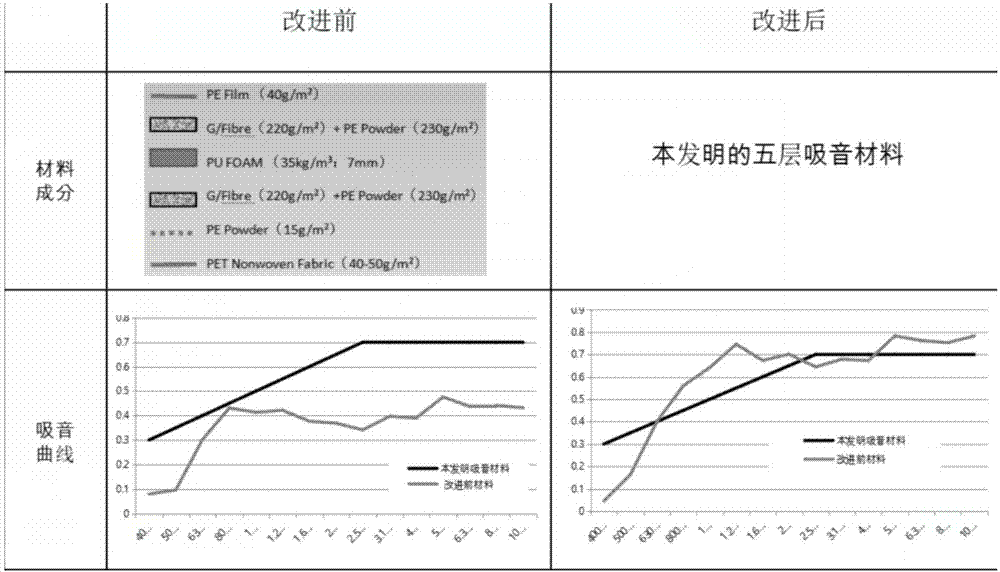

A ceiling and automobile technology, applied in the field of car interior materials, can solve the problems of reducing the mechanical properties of ceiling materials, different lengths of glass fibers, low modulus and areal density, etc., so as to improve the stability, strength and mechanical properties, improve the package Covering effect, the effect of enhancing bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

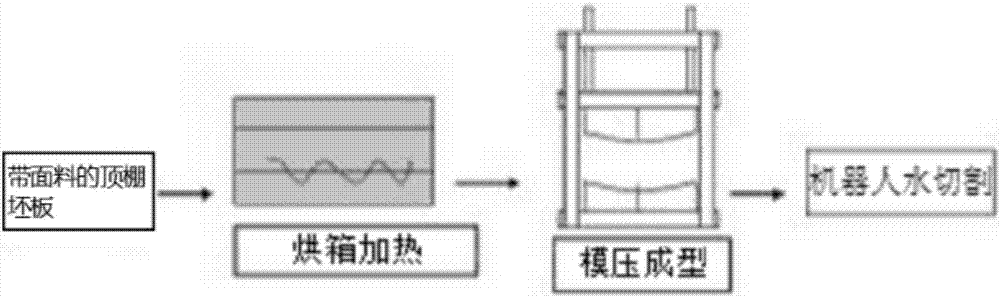

Method used

Image

Examples

Embodiment 1

[0045] A dry-process sound-absorbing ceiling for automobiles, which is formed by post-processing the ceiling blank. The ceiling blank is composed of 5-layer board structure, wherein the first layer is made of 2.5:1 weight ratio. Made of glass fiber and polyethylene rubber powder; the second layer is made of modified expanded polystyrene; the third layer is made of glass fiber modified polyethylene rubber powder; the fourth layer is Made of modified expanded polystyrene; the fifth layer is made of glass fiber and polyethylene rubber powder with a weight ratio of 2.5:1;

[0046] The polyethylene rubber powder modified by glass fiber is composed of the following raw materials in parts by weight:

[0047] Polyethylene rubber powder 80, glass fiber 90, γ-aminopropyltriethoxysilane 5, ricinoleic acid 2, calcium zeolite 20, tetraethyl silicate 70, activator 0.02, natural rubber 20, azodisiso Nitrile 0.5, carnauba wax 7, sulfur 0.2;

[0048] The preparation method of the polyethylen...

Embodiment 2

[0076] A dry-process sound-absorbing ceiling for automobiles, which is formed by post-processing the ceiling slabs. The ceiling slabs are composed of 5-layer board structures, wherein the first layer is made of Made of glass fiber and polyethylene rubber powder; the second layer is made of modified expanded polystyrene; the third layer is made of glass fiber modified polyethylene rubber powder; the fourth layer is Made of modified expanded polystyrene; the fifth layer is made of glass fiber and polyethylene rubber powder with a weight ratio of 2:1;

[0077] The polyethylene rubber powder modified by glass fiber is composed of the following raw materials in parts by weight:

[0078] Polyethylene rubber powder 60, glass fiber 70, γ-aminopropyltriethoxysilane 3, ricinoleic acid 1, calcium zeolite 10, tetraethyl silicate 60, activator 0.01, natural rubber 13, azodisiso Nitrile 0.4, carnauba wax 5, sulfur 0.1;

[0079] The preparation method of the polyethylene rubber powder of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com