Preparation method and application of stepped hole Beta molecular sieve

A molecular sieve and stepped pore technology, used in molecular sieve catalysts, preparation of organic compounds, molecular sieves and alkali exchange compounds, etc., can solve the problems of waste liquid discharge, destruction of molecular sieve crystal framework, and difficulty in controlling mesopore pore size, to avoid pollution, High BET specific surface area and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

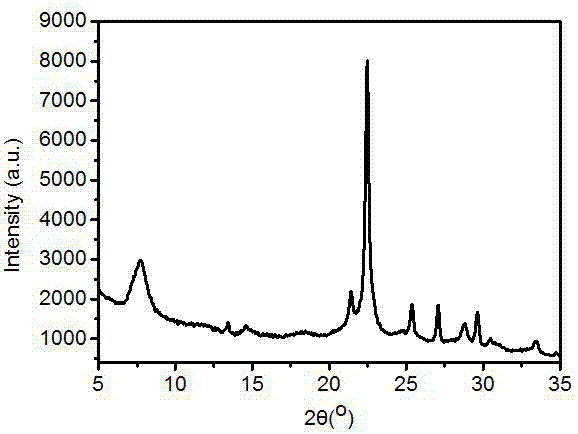

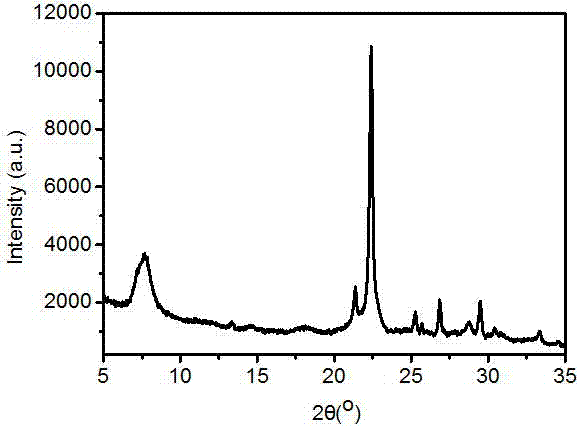

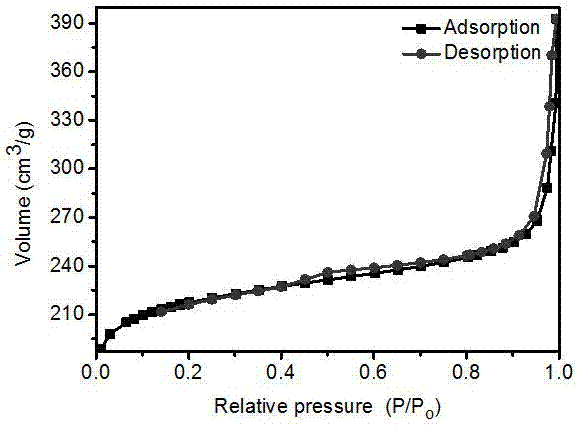

[0038] Dissolve 0.8 g of NaOH solid in 16.6 g of deionized water and stir well. Then add 0.65 g of kaolin activated by sub-molten salt, and stir in a water bath at 70°C for 4 hours; then slowly add 3.3 g of white carbon black and 0.3 g of Beta molecular sieve seeds into the above solution, and stir for 30 minutes; the molar ratio in terms of oxide For: 40SiO 2 :Al 2 o 3 :10Na 2 O:660H 2 O. The above mixture was charged into a stainless steel reaction kettle lined with polytetrafluoroethylene, and statically crystallized at 140° C. for 18 hours. After cooling, the solid product was filtered, washed, and dried at 120°C for 12 hours to obtain the original Beta molecular sieve powder. After powder X-ray diffraction analysis, it is determined that the product is a pure-phase BEA molecular sieve with a relative crystallinity of 110%. The BET specific surface area of the product is 666m 2 / g.

[0039] The Beta molecular sieve is used in the reaction of synthesizing ethyl ac...

Embodiment 2

[0041] Same as embodiment 1, only silicon source white carbon black is replaced by silica sol (SiO 2 Content is 30 wt%), keep the raw material molar ratio as 40SiO 2 :Al 2 o 3 :10Na 2 O:660H 2 O. After powder X-ray diffraction analysis, it is determined that the product is a pure-phase BEA molecular sieve with a relative crystallinity of 102%, and the BET specific surface area of the product is 605 m 2 / g.

[0042] The Beta molecular sieve is used in the reaction of synthesizing ethyl acetate from acetic acid and ethanol, and the reaction is continuously reacted in a fixed-bed reactor.

Embodiment 3

[0044] Same as Example 1, only the ratio of water to silicon is changed to 20 (that is, the amount of water added becomes 20.2 g), and the molar ratio in terms of oxides is: 40SiO 2 :Al 2 o 3 :10Na 2 O:800H 2 O. Static crystallization at 140°C for 18 hours. After powder X-ray diffraction analysis, it is determined that the product is a pure-phase BEA molecular sieve with a relative crystallinity of 105%, and the BET specific surface area of the product is 625 m 2 / g.

[0045] The Beta molecular sieve is used in the reaction of synthesizing ethyl acetate from acetic acid and ethanol, and the reaction is continuously reacted in a fixed-bed reactor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com