Mildew-proof treatment coating for printed wrapping paper for artistic design and preparation method of mildew-proof treatment coating

A technology for printing, packaging and anti-mildew treatment, which is applied in the direction of pigment-containing coating, paper, and anti-biological agent addition. It can solve the problems of single component and unsatisfactory anti-mildew effect, and achieve low production cost, slow overcoming speed and high efficiency. Anti-mildew effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

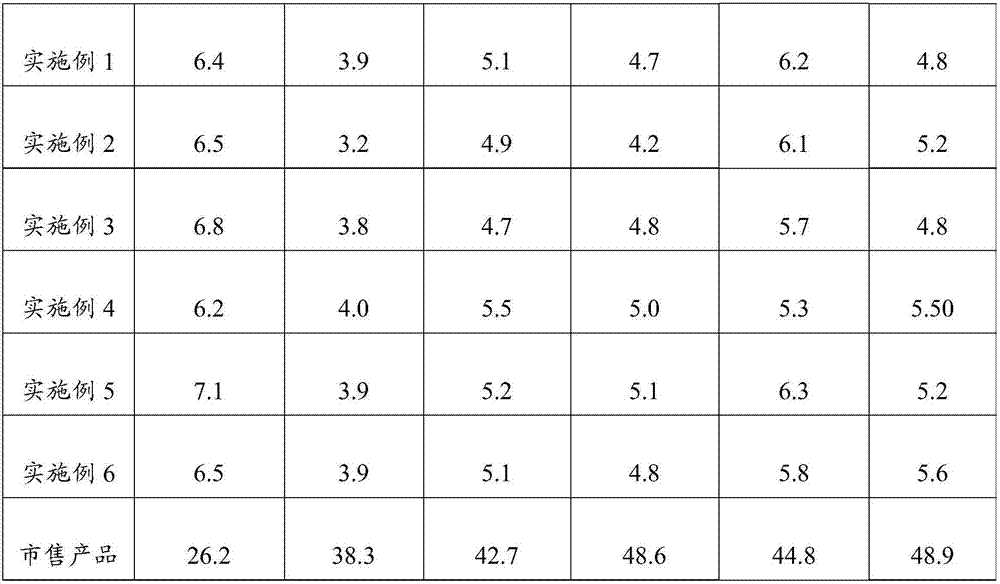

Embodiment 1

[0027] An anti-mildew treatment coating for artistic design printing packaging paper, its raw materials are composed of the following components in parts by weight: 25 parts of water-based acrylic modified polyurethane resin, 20 parts of paraben, 20 parts of silver-loaded zeolite, carbonic acid 1 part of sodium hydrogen, 5 parts of stearamide, 15 parts of plant antibacterial liquid, 3 parts of fennel oil, 3 parts of sodium carboxymethyl cellulose;

[0028] Wherein, the raw material of plant antibacterial liquid is made up of the component of following weight fraction:

[0029] 20 parts of cloves, 20 parts of hibiscus bark, 10 parts of kaempferia, 15 parts of perrin, and 3 parts of nepeta.

[0030] Specifically follow the steps below:

[0031] Step 1, weigh 20 parts of cloves, 20 parts of hibiscus bark, 10 parts of kaempferia, 15 parts of perrin, and 3 parts of nepeta;

[0032] Step 2, mix the components weighed in step 1 to obtain a mixture, add water equivalent to 10 times ...

Embodiment 2

[0038] An anti-mildew treatment coating for artistic design printing wrapping paper, its raw material consists of the following components in parts by weight: 28 parts of water-based acrylic modified polyurethane resin, 15 parts of p-hydroxybenzoic acid ester, 25 parts of silver-loaded zeolite, carbonic acid 2 parts of sodium hydrogen, 8 parts of stearamide, 12 parts of plant antibacterial liquid, 2 parts of fennel oil, 4 parts of polyethylene glycol;

[0039] Wherein, the raw material of plant antibacterial liquid is made up of the component of following weight fraction:

[0040] 25 parts of cloves, 18 parts of hibiscus bark, 12 parts of kaempferia, 12 parts of perrin, 4 parts of nepeta.

[0041] The preparation method is the same as that of Example 1, except that the formula is changed into that of Example 2.

Embodiment 3

[0043] An anti-mildew treatment coating for artistic design printing packaging paper, its raw materials are composed of the following components in parts by weight: 30 parts of water-based acrylic modified polyurethane resin, 10 parts of paraben, 30 parts of silver-loaded zeolite, carbonic acid 3 parts of sodium hydrogen, 5 parts of stearamide, 10 parts of plant antibacterial liquid, 1 part of fennel oil, 5 parts of polyvinyl alcohol;

[0044] Wherein, the raw material of plant antibacterial liquid is made up of the component of following weight fraction:

[0045] 30 parts of clove, 15 parts of hibiscus bark, 15 parts of kaempferen, 10 parts of perrin, and 5 parts of nepeta.

[0046] The preparation method is the same as in Example 1, except that the formula is changed into that of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com