Delivery device of embolic protection device in blood vessel

A delivery device and protector technology, which is applied in the field of medical devices, can solve the problems of blocking blood flow, difficult surgical operation, scratching the blood vessel wall, etc., achieve rapid delivery and recovery, ensure remote blood flow, and ensure stable blood flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

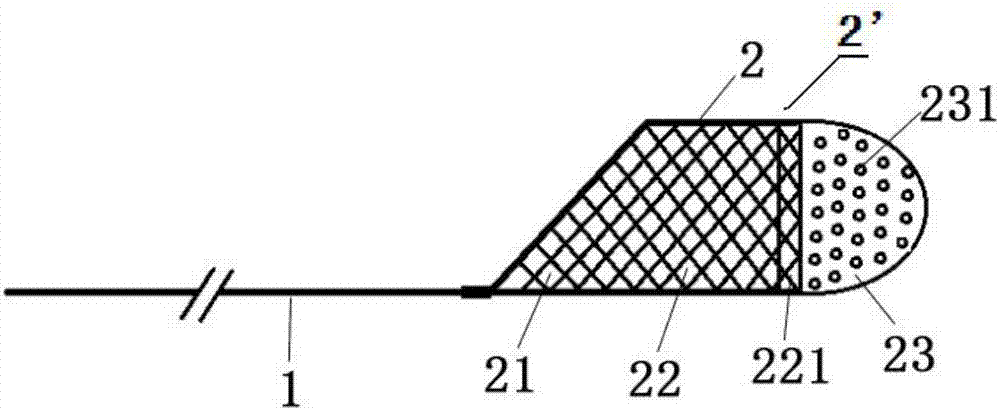

[0069] The mesh diameter on the metal mesh basket body is 700 μm.

[0070] (1) Dissolve Pellethane2363 series 80AE aromatic polyurethane in tetrahydrofuran, add 60 μm ammonium carbonate pore-forming agent, and stir well to form a pre-coating solution; the mass-volume ratio of Pellethane2363 series 80AE aromatic polyurethane to tetrahydrofuran is 0.02g / mL ; The mass ratio of ammonium carbonate and Pellethane2363 series 80AE aromatic polyurethane is 1:5;

[0071] (2) degassing the pre-coating solution in step (1) under nitrogen conditions with ultrasonic waves, the frequency of the ultrasonic wave is 80KHz, the temperature of the degassing treatment is 25°C, and the time is 5h to obtain the coating solution;

[0072] (3) Dip-coat the coating solution in step (2) on the entire distal end of the wire mesh basket body by dip-coating method under nitrogen gas, and dry at 25°C for 10 min under nitrogen gas for each dip-coating. After dipping for the first time and drying, the metal ...

Embodiment 2

[0077] The mesh diameter on the metal mesh basket body is 800 μm.

[0078] (1) Dissolve Pellethane2363 series 80AE aromatic polyurethane in chloroform, and add 120 μm of ammonium chloride pore-forming agent, stir well to form a pre-coating solution; the mass-volume ratio of Pellethane2363 series 80AE aromatic polyurethane to chloroform 0.001g / mL; the mass ratio of ammonium chloride to Pellethane2363 series 80AE aromatic polyurethane is 1:10;

[0079] (2) degassing the pre-coating solution in step (1) under nitrogen conditions with ultrasonic waves, the frequency of the ultrasonic wave is 100KHz, the temperature of the degassing treatment is 30°C, and the time is 8h to obtain the coating solution;

[0080] (3) Dip-coat the coating solution in step (2) on the entire distal end of the wire mesh basket body by dip-coating under nitrogen, and dry it at 30°C for 15 min under nitrogen for each dip-coating. After dipping for the first time and drying, the metal net blue body with coa...

Embodiment 3

[0085] The mesh diameter on the metal mesh basket body is 900 μm.

[0086] (1) Dissolve Pellethane2363 series 80AE aromatic polyurethane in methanol, add 70 μm polyethylene glycol pore-forming agent, and stir evenly to form a pre-coating solution; the mass-volume ratio of Pellethane2363 series 80AE aromatic polyurethane to methanol is 0.08g / mL; The mass ratio of polyethylene glycol to Pellethane2363 series 80AE aromatic polyurethane is 1:20;

[0087] (2) Degas the pre-coating liquid in step (1) under nitrogen condition with ultrasonic wave, the frequency of ultrasonic wave is 120KHz, the temperature of degassing treatment is 25°C, and the time is 7h, to obtain the coating liquid;

[0088] (3) Dip-coat the coating solution in step (2) on the entire distal end of the wire mesh basket body by dip-coating under nitrogen, and dry it at 30°C for 15 min under nitrogen for each dip-coating. After dipping for the first time and drying, the metal net blue body with coating is obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com