Catalyst for tail gas purification

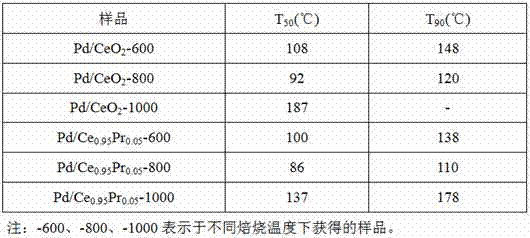

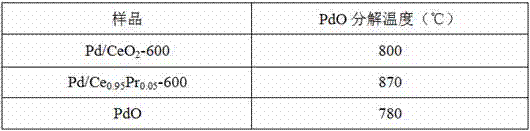

A tail gas purification and catalyst technology, applied in the direction of physical/chemical process catalysts, catalyst activation/preparation, heterogeneous catalyst chemical elements, etc., can solve problems such as weak anti-sintering ability, small specific surface area, poor mechanical stability, etc., and achieve mutual Enhanced action, increased decomposition temperature, improved activity and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) 3.84g Ce(NO 3 ) 3 ·6H 2 O and 0.50g Pr(NO 3 ) 3 ·6H 2 Add 50mL of methanol to dissolve, so that the total concentration of cations is 0.2mol / L, then add 1.58g of n-decyl alcohol, fully stir to dissolve; then add dropwise 50mL, 0.2mol / L methanol solution of tetramethylammonium hydroxide , mixed evenly and left for 24 hours; the resulting precipitate was filtered, washed with methanol, and dispersed in tetrahydrofuran to obtain solution A;

[0023] 2) 0.1g Pd(NO 3 ) 3 2H 2 O was dissolved in 50 mL of deionized water, then 0.5 g of polyvinylpyrrolidone was added, and superfine Pd nanoparticle sol was obtained through ultrasonic reduction; the ultrasonic frequency was 20 kHz, the output power was 200 W, and the ultrasonic time was 90 min;

[0024] 3) At room temperature, add 50mL methanol and 1.21g L-cysteine to the obtained Pd nanoparticle sol, stir and mix to obtain solution B;

[0025] 4) According to the volume ratio of 1:0.1, the obtained solution A was s...

Embodiment 2

[0028] 1) 7.00g Ce(NO 3 ) 3 ·6H 2 O and 1.68g Pr(NO 3 ) 3 ·6H 2 Add 100mL of methanol to dissolve, so that the total concentration of cations is 0.2mol / L, then add 3.16g of n-decyl alcohol, fully stir to dissolve; then add dropwise 100mL, 0.2mol / L methanol solution of tetramethylammonium hydroxide , mixed evenly and left for 24 hours; the resulting precipitate was filtered, washed with methanol, and dispersed in tetrahydrofuran to obtain solution A;

[0029] 2) 0.1g Pd(NO 3 ) 3 2H 2 O was dissolved in 50mL deionized water, then 0.5g polyethylene glycol was added, and superfine Pd nanoparticle sol was obtained by ultrasonic reduction; the ultrasonic frequency was 20kHz, the output power was 500W, and the ultrasonic time was 30min;

[0030] 3) At room temperature, add 50 mL of methanol and 2.18 g of 11-mercaptoundecanoic acid to the obtained Pd nanoparticle sol, and stir to obtain solution B;

[0031] 4) Slowly add the obtained solution A to the obtained solution B unde...

Embodiment 3

[0034] 1) 5.90g Ce(NO 3 ) 3 ·6H 2 O and 2.78g Pr(NO 3 ) 3 ·6H 2 Add 80mL of methanol to dissolve, so that the total concentration of cations is 0.2mol / L, then add 0.912g of ethylene glycol, fully stir to dissolve; then add dropwise 40mL, 0.2mol / L of tetramethylammonium hydroxide in methanol solution, mixed evenly and left for 24 hours; the resulting precipitate was filtered, washed with methanol, and dispersed in tetrahydrofuran to obtain solution A;

[0035] 2) 0.1g Pd(NO 3 ) 3 2H 2 O was dissolved in 50mL deionized water, then 0.5g polyethyleneimine was added, and superfine Pd nanoparticle sol was obtained through ultrasonic reduction; the ultrasonic frequency was 20kHz, the output power was 250W, and the ultrasonic time was 50min;

[0036] 3) At room temperature, add 50 mL of methanol and 2 g of L-arginine to the obtained Pd nanoparticle sol, stir and mix to obtain solution B;

[0037] 4) Slowly add the obtained solution A to the obtained solution B under stirring co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com