Maintaining device for coating roller of carbon tetrachloride karst water deposit and operating method for maintaining device

A carbon tetrachloride, karst water technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. Problems such as water accumulation and water can not be filtered out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

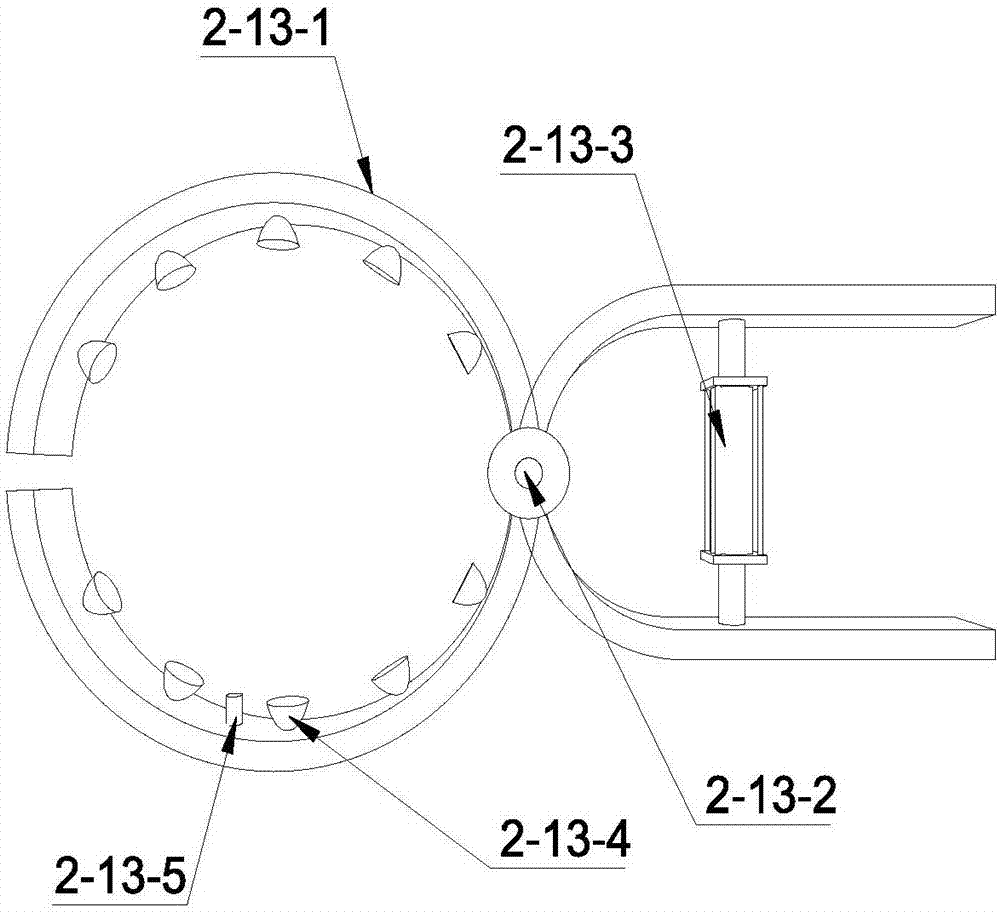

[0074] Manufacture the automatic spray cleaning liquid head 2-13-4 of the present invention according to the following steps, and by weight fraction:

[0075]Step 1: Add 544 parts of ultrapure water with a conductivity of 0.44μS / cm into the reactor, start the stirrer in the reactor at a speed of 94rpm, start the heating pump, and raise the temperature in the reactor to 64°C; add in sequence 64 parts of 1,1,1,2-tetrafluoro-2-chloroethane, 84 parts of tetrachlorodifluoroethane, 144 parts of 1,1-difluoroethane, stirred until completely dissolved, adjusted to pH 4.4, Adjust the rotation speed of the agitator to 144rpm, the temperature is 94°C, and the esterification reaction is carried out for 44 hours;

[0076] Step 2: Take 84 parts of trimethylol melamine resin and 74 parts of magnetic melamine-formaldehyde resin for pulverization, the powder particle size is 414 mesh; 144 parts of ethyl]amino]-3-nitrobenzoate were mixed evenly, spread on the tray with a thickness of 44mm, and ...

Embodiment 2

[0081] Manufacture the automatic spray cleaning liquid head 2-13-4 of the present invention according to the following steps, and by weight fraction:

[0082] Step 1: Add 1404 parts of ultrapure water with a conductivity of 0.74μS / cm into the reactor, start the stirrer in the reactor at a speed of 444rpm, start the heating pump, and raise the temperature in the reactor to 84°C; add in sequence 144 parts of 1,1,1,2-tetrafluoro-2-chloroethane, 44 parts of tetrachlorodifluoroethane, 454 parts of 1,1-difluoroethane, stirred until completely dissolved, adjusted to pH 7.4, Adjust the rotation speed of the agitator to 454rpm, the temperature is 164°C, and the esterification reaction takes 54 hours;

[0083] Step 2: Take 194 parts of trimethylol melamine resin and 154 parts of magnetic melamine-formaldehyde resin for pulverization, the powder particle size is 544 mesh; Base]amino]-3-nitrobenzoic acid ethyl ester 444 parts were mixed evenly, spread in the tray, the thickness of the la...

Embodiment 3

[0088] Manufacture the automatic spray cleaning liquid head 2-13-4 of the present invention according to the following steps, and by weight fraction:

[0089] Step 1: Add 1104 parts of ultrapure water with a conductivity of 0.54μS / cm into the reactor, start the stirrer in the reactor at a speed of 244rpm, start the heating pump, and raise the temperature in the reactor to 74°C; add in sequence 124 parts of 1,1,1,2-tetrafluoro-2-chloroethane, 114 parts of tetrachlorodifluoroethane, 354 parts of 1,1-difluoroethane, stirred until completely dissolved, adjusted to pH 6.4, Adjust the rotation speed of the agitator to 254rpm, the temperature is 134°C, and the esterification reaction is carried out for 48 hours;

[0090] Step 2: Take 124 parts of trimethylol melamine resin and 134 parts of magnetic melamine-formaldehyde resin for pulverization, the powder particle size is 464 mesh; add 2-[[(2'-cyanobiphenyl-4-yl)formaldehyde Base]amino]-3-nitrobenzoic acid ethyl ester 344 parts are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com