Water quality improver for aquaculture and preparation method of water quality improver

A water quality improver, aquaculture technology, applied in water/sewage treatment, water treatment parameter control, chemical instruments and methods, etc., can solve problems such as incomplete ammonia nitrogen, hydrogen sulfide, nitrite, etc., and reduce water eutrophication. transformation, high efficiency, and the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

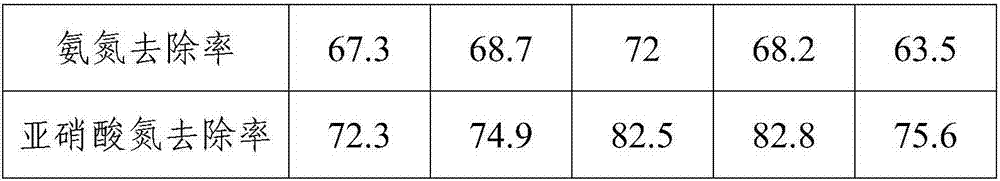

Embodiment 1

[0021] A water quality improver for aquaculture, made of the following raw materials in parts by weight: 20 parts of Bacillus subtilis, 20 parts of Rhodobacter sphaeroides, 4 parts of liquid ozone, 3 parts of titanium dioxide powder, 5 parts of phosphoric acid, and magnesium oxide powder 1 part, 2 parts of potassium chloride powder, 1 part of vitamin, 3 parts of oyster shell powder.

[0022] A water quality improver for aquaculture, the preparation method of which comprises the following steps:

[0023] (1) Bacillus subtilis and Rhodobacter sphaeroides were inoculated into potato dextrose agar medium, and cultured in a constant temperature light incubator at 25°C for 4 days, then cultured for 4 days under dark conditions, and the culture solution was taken for subsequent use;

[0024] (2) Put liquid ozone and titanium dioxide powder in the reaction kettle, add water equal to the sum of the two masses, ultrasonically disperse it for 10 minutes, put it into a laser cladding mach...

Embodiment 2

[0028] A water quality improver for aquaculture, made of the following raw materials in parts by weight: 30 parts of Bacillus subtilis, 30 parts of Rhodobacter sphaeroides, 8 parts of liquid ozone, 7 parts of titanium dioxide powder, 9 parts of phosphoric acid, and magnesium oxide powder 5 parts, 6 parts potassium chloride powder, 4 parts vitamins, 7 parts oyster shell powder.

[0029] A water quality improver for aquaculture, the preparation method of which comprises the following steps:

[0030] (1) Bacillus subtilis and Rhodobacter sphaeroides were inoculated into potato dextrose agar medium, and cultured in a constant temperature light incubator at 30°C for 4 days, then cultured for 4 days under dark conditions, and the culture solution was taken for subsequent use;

[0031] (2) Put liquid ozone and titanium dioxide powder in the reaction kettle, add water equal to the sum of the two masses, ultrasonically disperse it for 20 minutes, put it into a laser cladding machine, a...

Embodiment 3

[0035] A water quality improver for aquaculture, made of the following raw materials in parts by weight: 25 parts of Bacillus subtilis, 25 parts of Rhodobacter sphaeroides, 5 parts of liquid ozone, 4 parts of titanium dioxide powder, 6 parts of phosphoric acid, and magnesium oxide powder 2 parts, 3 parts potassium chloride powder, 2 parts vitamins, 4 parts oyster shell powder.

[0036] A water quality improver for aquaculture, the preparation method of which comprises the following steps:

[0037] (1) Bacillus subtilis and Rhodobacter sphaeroides were inoculated into potato dextrose agar medium, and cultured in a constant temperature light incubator at 26°C for 4 days, then cultured for 4 days under dark conditions, and the culture solution was taken for subsequent use;

[0038] (2) Put liquid ozone and titanium dioxide powder in the reaction kettle, add water equal to the sum of the two masses, ultrasonically disperse it for 12 minutes, put it into a laser cladding machine, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com