Polyvinyl butyral synthesizing method

A polyvinyl butyral and synthesis method technology, which is applied in the field of polymer resin synthesis, can solve the problems of complex process and high energy consumption, and achieve the effects of accelerating the reaction rate, reducing energy consumption, and ensuring consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

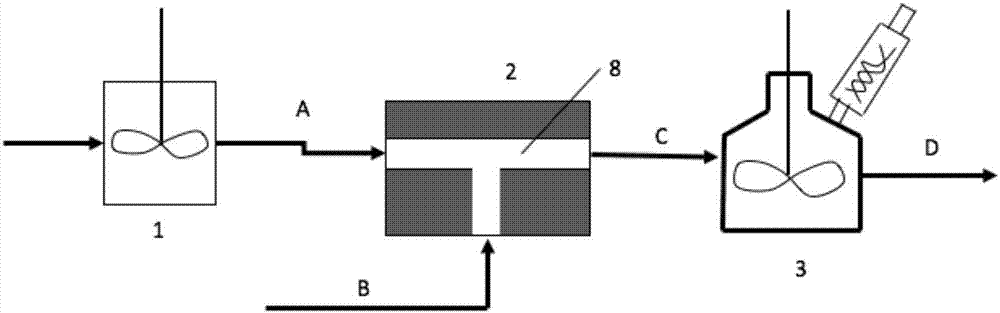

[0033] The synthetic technique of present embodiment polyvinyl butyral is as figure 1 .

[0034] Reaction conditions: the massfraction of polyvinyl alcohol in raw material A is 2%, the mass ratio of hydrogen chloride and polyvinyl alcohol is 0.5:1, and the solvent of raw material A is water; Raw material B is n-butyraldehyde, controls n-butyraldehyde and The mass ratio of polyvinyl alcohol in raw material A is 0.8:1; the temperature of the first-stage high-temperature reaction is 50°C, and the reaction time is 9.8s; the temperature of the second-stage low-temperature aging is 30°C, and the reaction time is 5h.

[0035] Reaction device: there is a T-shaped tiny channel inside the microreactor, the angle between the inlet channel of raw material A and raw material B is 90°, the angle between the outlet channel and the inlet channel of raw material A is 180°; the size of the inlet channel is 1.0mm×0.5mm , the outlet channel size is 1.0mm×1.0mm. The aging reactor is a tank react...

Embodiment 2

[0038] The synthetic technique of present embodiment polyvinyl butyral is as figure 1 .

[0039] Reaction conditions: the massfraction of polyvinyl alcohol in raw material A is 6%, the mass ratio of hydrogen chloride and polyvinyl alcohol is 0.3:1, and the solvent of raw material A is water; Raw material B is n-butyraldehyde, controls n-butyraldehyde and The mass ratio of polyvinyl alcohol in raw material A is 1:1; the temperature of the first-stage high-temperature reaction is 70°C, and the reaction time is 9.8s; the temperature of the second-stage low-temperature aging is 50°C, and the reaction time is 5h.

[0040] Reaction device: there is a T-shaped tiny channel inside the microreactor, the angle between the inlet channel of raw material A and raw material B is 90°, the angle between the outlet channel and the inlet channel of raw material A is 180°; the size of the inlet channel is 1.0mm×0.5mm , the outlet channel size is 1.0mm×1.0mm. The aging reactor is a tank reactor...

Embodiment 3

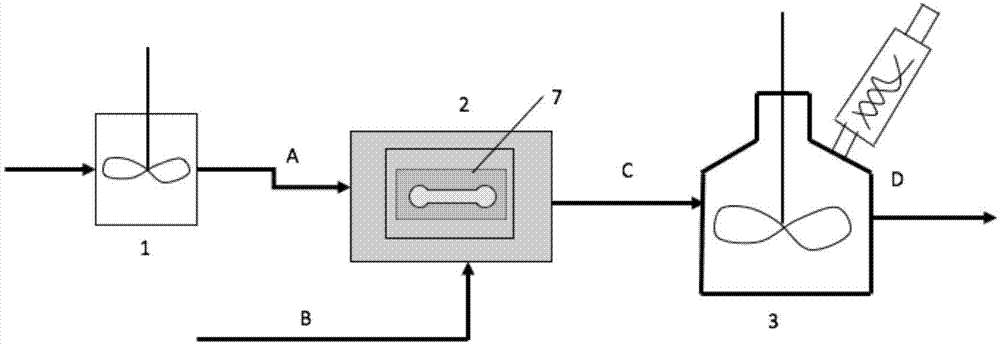

[0043] The synthetic technique of present embodiment polyvinyl butyral is as figure 2 .

[0044] Reaction condition: the massfraction of polyvinyl alcohol in raw material A is 8%, the mass ratio of hydrogen chloride and polyvinyl alcohol is 0.1:1, and the solvent of raw material A is water; Raw material B is n-butyraldehyde, controls n-butyraldehyde and The mass ratio of polyvinyl alcohol in raw material A is 0.6:1; the temperature of the first-stage high-temperature reaction is 60°C, and the reaction time is 9.8s; the temperature of the second-stage low-temperature aging is 45°C, and the reaction time is 5h.

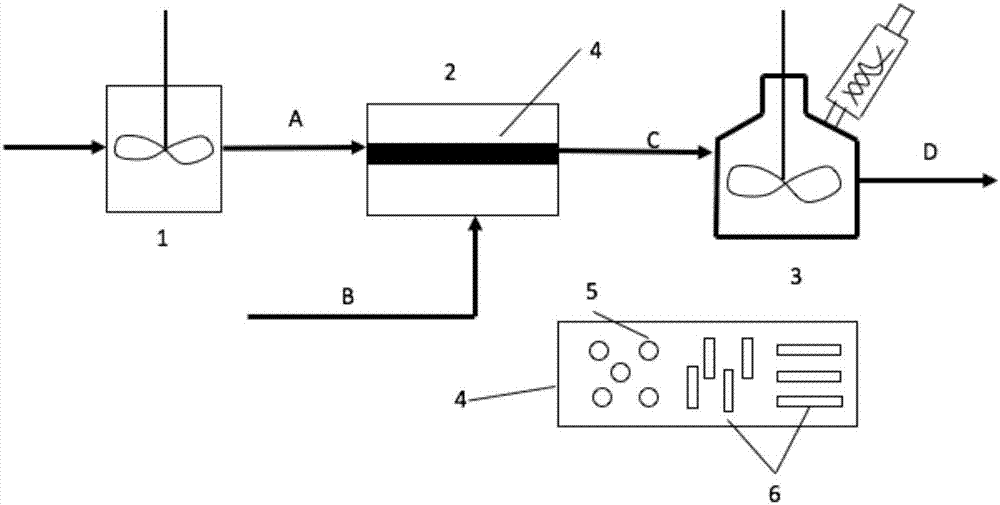

[0045] Reaction device: There is a metal sintered membrane with a pore size of 2 μm inside the microreactor. The aging reactor is a tank reactor with a heat exchange jacket.

[0046] Reaction result: the degree of acetalization of the product polyvinyl butyral is 79.8%, and the macroscopic appearance of the product is white finely dispersed particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com