Polyurethane paint used on windward sides of wind power blade machines, and preparation method thereof

A polyurethane coating and wind blade technology, applied in anti-corrosion coatings, fire-resistant coatings, anti-fouling/underwater coatings, etc., can solve problems such as erosion and wear on the windward side of blades, achieve good salt spray resistance, reduce production costs, and strong use. Effects on longevity and safety of use

Inactive Publication Date: 2017-12-08

INNER MONGOLIA AGRICULTURAL UNIVERSITY

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The invention provides a polyurethane coating for the windward side of a wind blade machine and a preparation method thereof, which can solve the problem in the prior art that the windward side of the blade in the wind blade machine is squeezed, deformed, eroded and worn

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0020] A specific embodiment of the present invention will be described in detail below, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

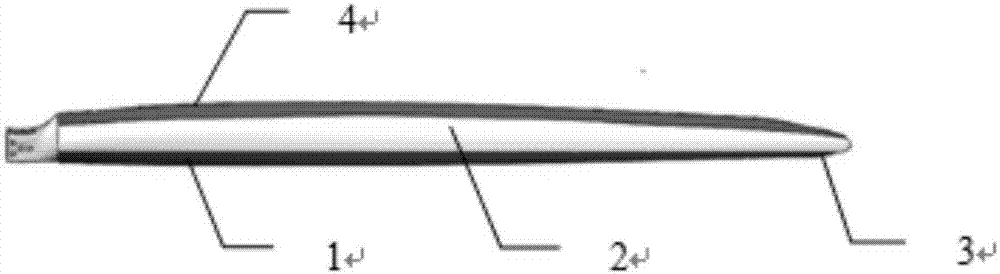

The invention discloses a polyurethane paint used on windward sides of wind power blade machines, and a preparation method thereof. The polyurethane paint comprises modified phenolic resin reinforced polyurethane, urea-formaldehyde resin, ethylene-vinyl acetate copolymer, an anti-settling agent, rutile titanium dioxide, flake graphite powder, methyl methacrylate, coumarone, zinc oxide, kaolin, diethylene glycol, an aromatic hydrocarbon oil, a stabilizing agent, silicon dioxide, an antifoaming agent, a dispersant, a base material wetting agent, and a bactericide. The polyurethane paint is long in service life, and high in using safety, is capable of reducing blade production cost and maintenance cost in operation process. It is confirmed by a plurality of performance tests that the polyurethane paint is excellent in adhesive force, wear resistance, weatherability, salt spray resistance, damp heat resistance, and flexibility, can be used on wind driven generator blades, and is capable of protecting operation of wind driven generator blades for a long term.

Description

technical field [0001] The invention relates to the technical field of coating chemicals, in particular to a polyurethane coating for the windward side of a wind blade machine and a preparation method thereof. Background technique [0002] With the development and application of renewable energy, wind energy has become one of the main energy sources in the world due to its rich resources, wide distribution, and cleanliness. The development of wind power and wind power industry has also attracted much attention. The blade is an important part of the wind turbine, and it is a device for capturing and converting wind energy. Its performance and service life directly affect the normal operation of the wind turbine and the efficiency of the system. Therefore, the reliability and safety of blades are particularly important, which is the key to ensure the normal operation of wind turbines. [0003] Due to the complex and changeable environment and climate of the wind field, when t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D4/06C09D4/02C09D5/08C09D5/14C09D7/12

CPCC09D4/06C09D5/08C09D5/14C09D5/18

Inventor 张永高津

Owner INNER MONGOLIA AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com