A preparation method of para-aramid nanofiber composite lithium-ion battery separator

A para-aramid and ion battery technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of increased surface energy of the coating slurry, poor adhesion of the separator, and poor battery performance. Save solvent and energy, improve high temperature resistance, low viscosity and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the p-aramid fiber nanofiber composite lithium-ion battery diaphragm that the present invention proposes comprises the following steps:

[0023] (1) Preparation of para-aramid polymerization slurry:

[0024] Under the protection of nitrogen, add 1.5 to 3 parts of solubilizing salt and 0.5 to 2.5 parts of p-phenylenediamine to 100 parts by weight of N-methyl-2-pyrrolidone with a water content of less than 100 ppm, stir in an ice-water bath until completely dissolved, Then add terephthaloyl dichloride, keep stirring to carry out polymerization, wherein the molar ratio of terephthaloyl dichloride to p-phenylenediamine is: 1.000-1.010, polymerize for 10-30 minutes, stop stirring, and obtain para-aramid polymerization pulp material, wherein the solubilizing salt is calcium chloride or lithium chloride;

[0025] (2) Coating:

[0026] Coating the para-aramid polymerization slurry on the surface of the base film by a coating method to prepare a coati...

Embodiment 1

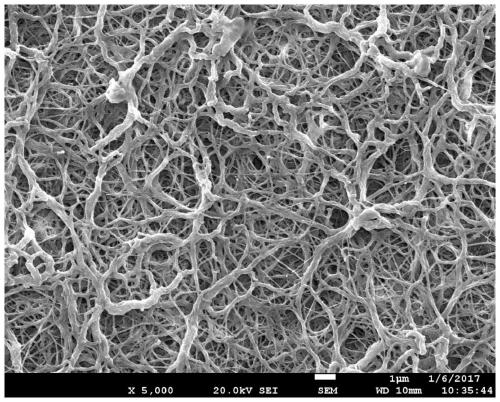

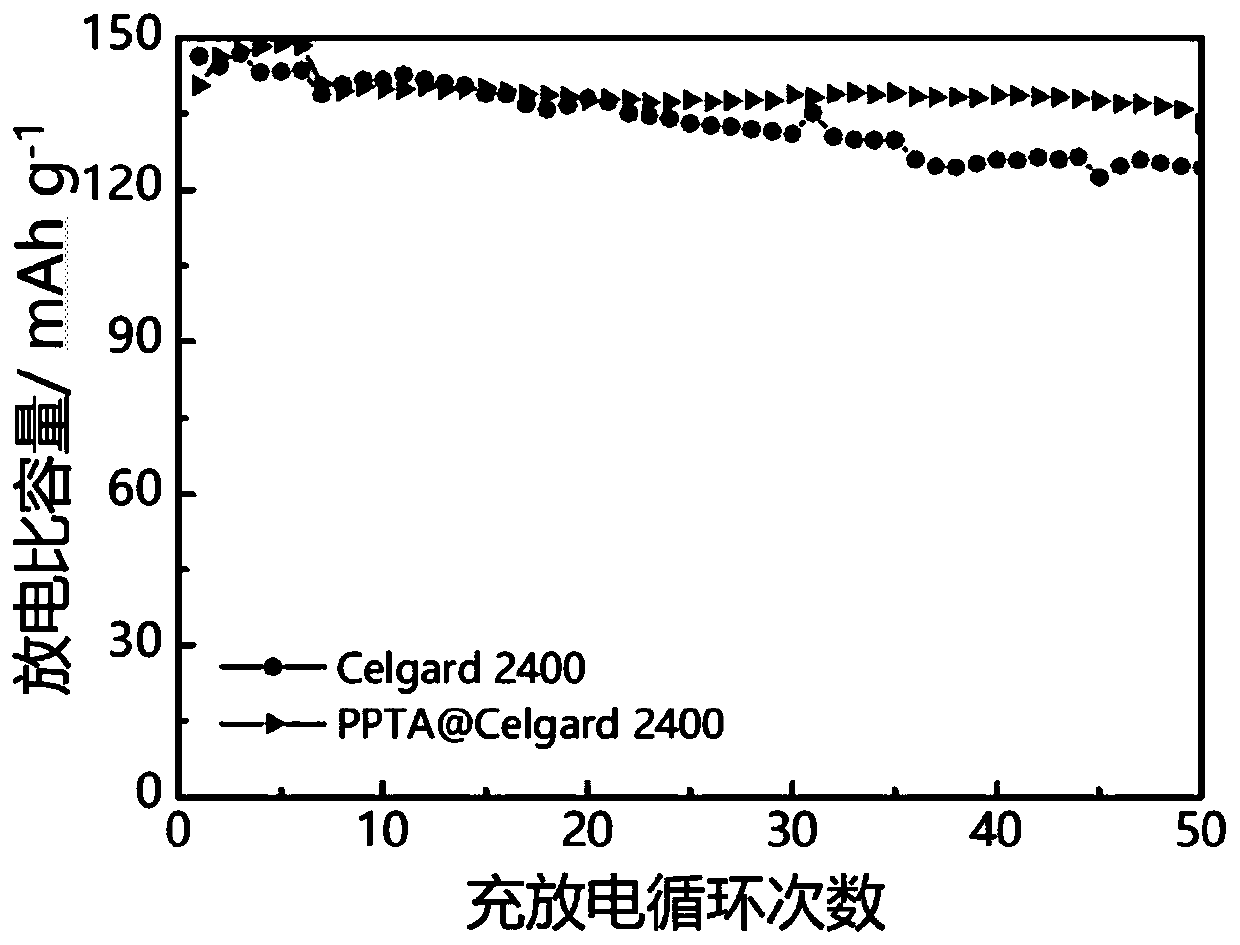

[0034] Measure 1 LN-methyl-2-pyrrolidone, add 20.00g of calcium chloride and 17.30g of p-phenylenediamine in a nitrogen protection and ice-water bath, stir at a speed of 500rpm until completely dissolved, then reduce the stirring speed to Raise to 800rpm and add 32.71g of terephthaloyl chloride to it, stop stirring after 12 minutes of reaction; spread a polypropylene porous film with a thickness of 25 μm on an automatic coating machine, adjust the height of the scraper to 150 μm, at a speed of 3m / min Coating; immerse the coated diaphragm in a coagulation bath containing N-methyl-2-pyrrolidone: water = 9:1 (v:v) to solidify, take it out after 30 seconds, wash it with water for 20 seconds, and set it at 100°C and drying for 15 minutes to obtain a lithium-ion battery separator composed of para-aramid fiber nanofibers. The thickness of the lithium-ion battery separator composed of para-aramid nanofibers is 30 μm, and the thickness of the para-aramid nanofiber layer is 5 μm.

[00...

Embodiment 2

[0037]Measure 1 LN-methyl-2-pyrrolidone, add 15.00g of calcium chloride and 5.00g of p-phenylenediamine in a nitrogen protection and ice-water bath, stir at a speed of 500rpm until completely dissolved, then reduce the stirring speed to Increase to 800rpm and add 9.45g terephthaloyl chloride to it, stop stirring after 30 minutes of reaction; spread a polyethylene porous film with a thickness of 20 μm on the automatic coating machine, adjust the height of the scraper to 50 μm, at a speed of 3m / min Coating; immerse the coated diaphragm in a coagulation bath containing N-methyl-2-pyrrolidone: water = 19:1 (v:v) to solidify, take it out after 10 seconds, wash it with water for 8 seconds, and set it at 100°C and dry for 1 min to obtain a lithium-ion battery separator composed of para-aramid fiber nanofibers. The thickness of the lithium-ion battery separator composed of para-aramid nanofibers is 20.5 μm, and the thickness of the para-aramid nanofiber layer is 0.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com