Method for preparing microporous polysaccharide drug-carrying microspheres

A technology of drug-loading microspheres and polysaccharides, which is applied in microcapsules, nanocapsules, drug combinations, etc., to achieve the effects of good biocompatibility, reduction of environmental pollution, and enhancement of transmembrane ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

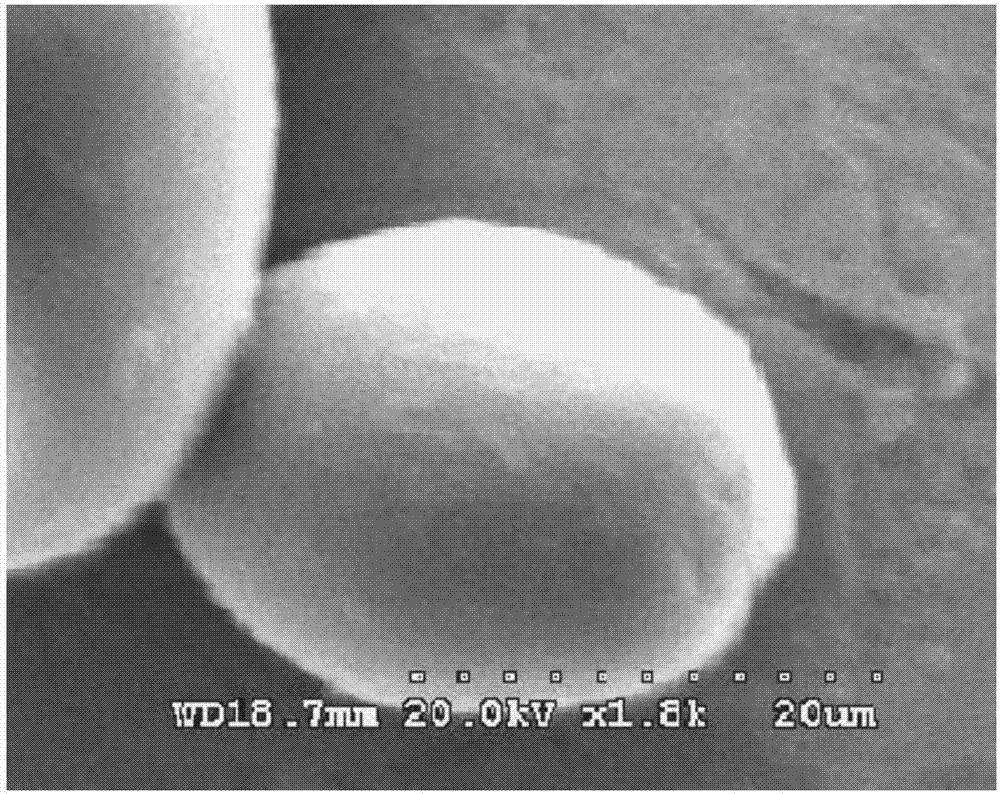

Image

Examples

Embodiment 1

[0031] 1. Select high-quality potato starch: mix the potato plant starch with 75% ethanol in a ratio of 1:2-5 times after removing the vegetable protein, and fully stir at 50-100 rpm for 30-60 minutes to form an emulsion, and let it stand After 24 hours, ethanol was removed, and then washed with water. Add 3-5 times of purified water, keep stirring, let stand to separate layers, discard the supernatant, and then repeatedly wash the lower emulsion 3-5 times.

[0032] 2. Emulsification: The inactivated and virus-removed starch emulsion is prepared into 12-20% wet starch and added to the extrusion extruder. The starch is rubbed and extruded by the screw shaft to generate heat and gelatinized, and then passed through the pore size 3- High-pressure extrusion with small holes of 8 mm, repeated 2-10 times, to obtain pasty primary emulsified starch, emulsification temperature 120-160 ° C.

[0033] 3. Enzymatic hydrolysis and cross-linking: Cool the above-mentioned preliminary emulsif...

Embodiment 2

[0041] 1. Select high-quality potato starch: mix the potato plant starch with 75% ethanol in a ratio of 1:2-5 times after removing the vegetable protein, and fully stir at 50-100 rpm for 30-60 minutes to form an emulsion, and let it stand After 24 hours, ethanol was removed, and then washed with water. Add 3-5 times of purified water, keep stirring, let stand to separate layers, discard the supernatant, and then repeatedly wash the lower emulsion 3-5 times.

[0042] 2. Emulsification: The inactivated and virus-removed starch emulsion is prepared into 12-20% wet starch and added to the extrusion extruder. The starch is rubbed and extruded by the screw shaft to generate heat and gelatinized, and then passed through the pore size 3- High-pressure extrusion with small holes of 8 mm, repeated 2-10 times, to obtain pasty primary emulsified starch, emulsification temperature 120-160 ° C.

[0043] 3. Enzymatic hydrolysis and cross-linking: Cool the above-mentioned preliminary emulsif...

Embodiment 3

[0050] 1. Select high-quality potato starch: mix the potato plant starch with 75% ethanol in a ratio of 1:2-5 times after removing the vegetable protein, and fully stir at 50-100 rpm for 30-60 minutes to form an emulsion, and let it stand After 24 hours, ethanol was removed, and then washed with water. Add 3-5 times of purified water, keep stirring, let stand to separate layers, discard the supernatant, and then repeatedly wash the lower emulsion 3-5 times.

[0051] 2. Emulsification: The inactivated and virus-removed starch emulsion is prepared into 12-20% wet starch and added to the extrusion extruder. The starch is rubbed and extruded by the screw shaft to generate heat and gelatinized, and then passed through the pore size 3- High-pressure extrusion with small holes of 8 mm, repeated 2-10 times, to obtain pasty primary emulsified starch, emulsification temperature 120-160 ° C.

[0052] 3. Enzymatic hydrolysis and cross-linking: Cool the above-mentioned preliminary emulsif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com