Graphene/sodium alga acid/carbon nano tube compound elastic aerogel applied in strain sensor and preparation method of graphene/sodium alga acid/carbon nano tube compound elastic aerogel

A carbon nanotube composite and strain sensor technology, which is applied in the direction of airgel preparation, chemical instruments and methods, instruments, etc., can solve the problems of complex preparation process, limit the practical application of mixed airgel, and unstable resistance, and achieve the goal of preparing The method is simple and practical, the effect of excellent strain sensing performance and sensitive resistance change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

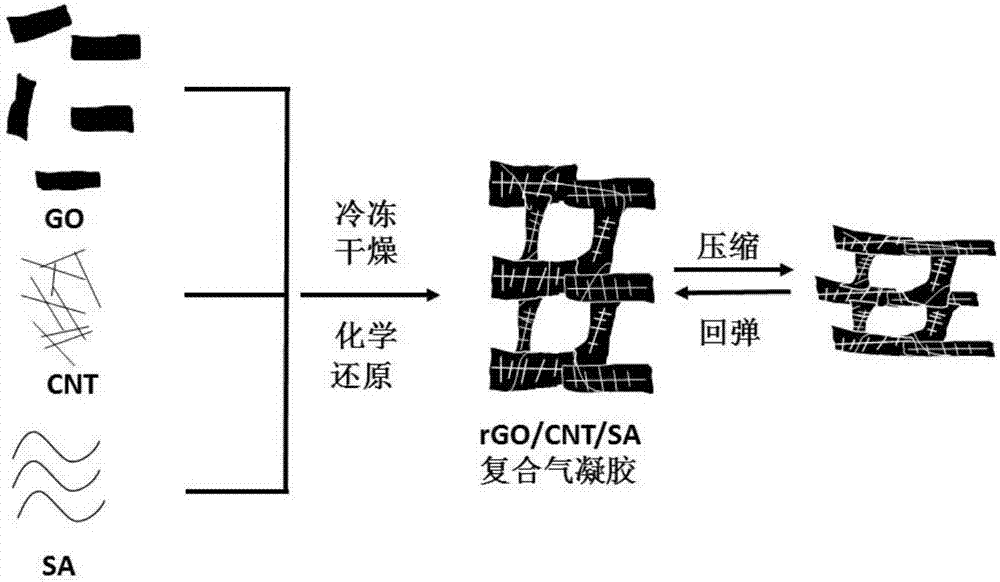

[0051] The preparation of the graphene / sodium alginate / carbon nanotube composite elastic airgel for strain sensor specifically includes the following steps:

[0052] (1) Place the prepared graphene oxide in deionized water, and adjust the concentration of the graphene oxide aqueous solution to 5 mg·mL -1 , sonicate for 2.5 h to disperse evenly; then sodium alginate (SA) solution (1 mg·mL -1 ), graphene oxide (GO) solution (1 mg·mL -1 ) and carbon nanotubes (CNTs) suspension (1 mg·mL -1 ) was mixed according to the mass ratio GO:SA:CNTs=GO:SA:CNTs=20:7:3, and the mixture was stirred continuously at 140rpm for 3.5 hours, then put into a freeze dryer, and freeze-dried at -58°C for 48 hours. Obtain composite airgel;

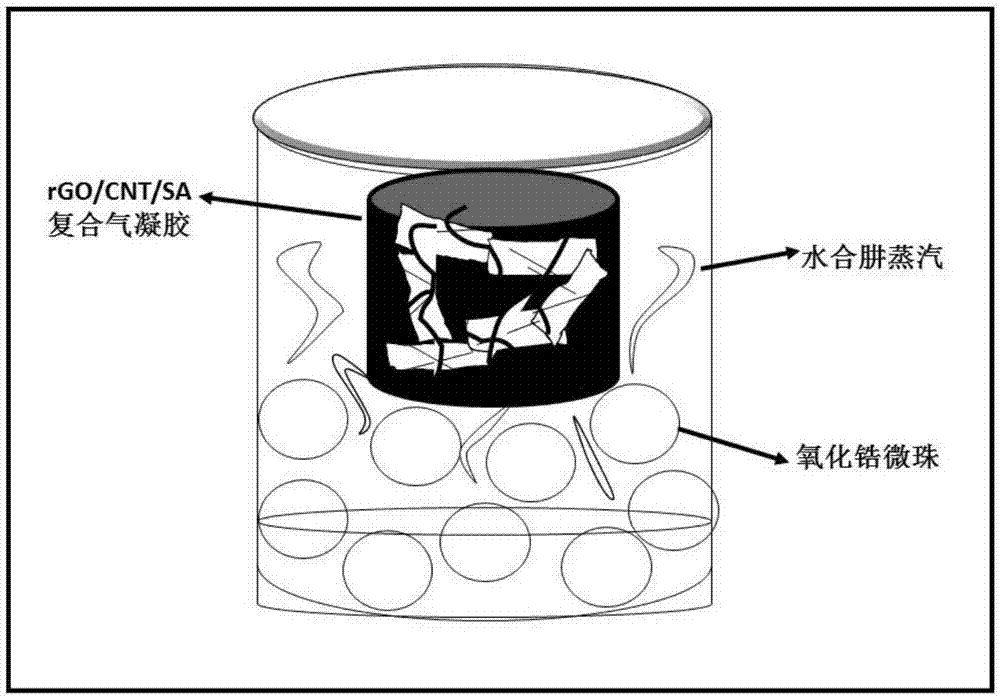

[0053] (2) Then, the obtained composite airgel was placed in a tetrafluoroethylene reactor (ceramic microbeads were silicon nitride), and 4 N 2 ·H 2 Under O steam atmosphere, the reduction reaction was carried out at 100°C for 8 hours; after the reaction, it wa...

Embodiment 2

[0055] The preparation of the graphene / sodium alginate / carbon nanotube composite elastic airgel for strain sensor specifically includes the following steps:

[0056] (1) Place the prepared graphene oxide in deionized water, and adjust the concentration of the graphene oxide aqueous solution to 3 mg•mL -1 , sonicate for 1.5 h to disperse evenly; then sodium alginate (SA) solution (3 mg·mL -1 ), graphene oxide (GO) solution (3mg·mL -1 ) and carbon nanotubes (CNTs) suspension (3mg·mL -1 ) After mixing according to the mass ratio GO:SA:CNTs=20:5:5, the mixture was continuously stirred at 130rpm for 2.5 hours, then put into a freeze dryer, and freeze-dried at -65°C for 48 hours to obtain a composite airgel;

[0057] (2) Then, the obtained composite airgel was placed in a tetrafluoroethylene reactor (ceramic microbeads were silicon nitride), and 4 N 2 ·H 2 Under O steam atmosphere, carry out the reduction reaction at 85°C for 10.5 hours; after the reaction, let it stand and ven...

Embodiment 3

[0059] The preparation of the graphene / sodium alginate / carbon nanotube composite elastic airgel for strain sensor specifically includes the following steps:

[0060] (1) Place the prepared graphene oxide in deionized water, and adjust the concentration of the graphene oxide aqueous solution to 4 mg•mL -1 , sonicated for 1h to disperse evenly; then sodium alginate (SA) solution (4mg·mL -1 ), graphene oxide (GO) solution (4 mg·mL -1 ) and carbon nanotubes (CNTs) suspension (4mg·mL -1 ) After mixing according to the mass ratio GO:SA:CNTs=20:3:7, the mixture was continuously stirred at 150rpm for 2 hours, then put into a freeze dryer, and freeze-dried at -60°C for 48 hours to obtain a composite airgel;

[0061] (2) Then, the obtained composite airgel was placed in a tetrafluoroethylene reactor (ceramic microbeads were zirconia), and 4 N 2 ·H 2 Under O steam atmosphere, carry out reduction reaction at 90 DEG C for 10 hours; After the reaction is over, let it stand for ventilat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com