New energy chemical fiber product raw material storage tank

A raw material storage tank and new energy technology, which is applied in the direction of layered products, metal layered products, synthetic resin layered products, etc., can solve the problem of tank roof damage, need to stop tanks, clean tanks, poor anticorrosion durability of tank roofs, etc. Increase safety hazards and other issues to achieve good construction environment, improve photoelectric replacement efficiency, and reliable principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

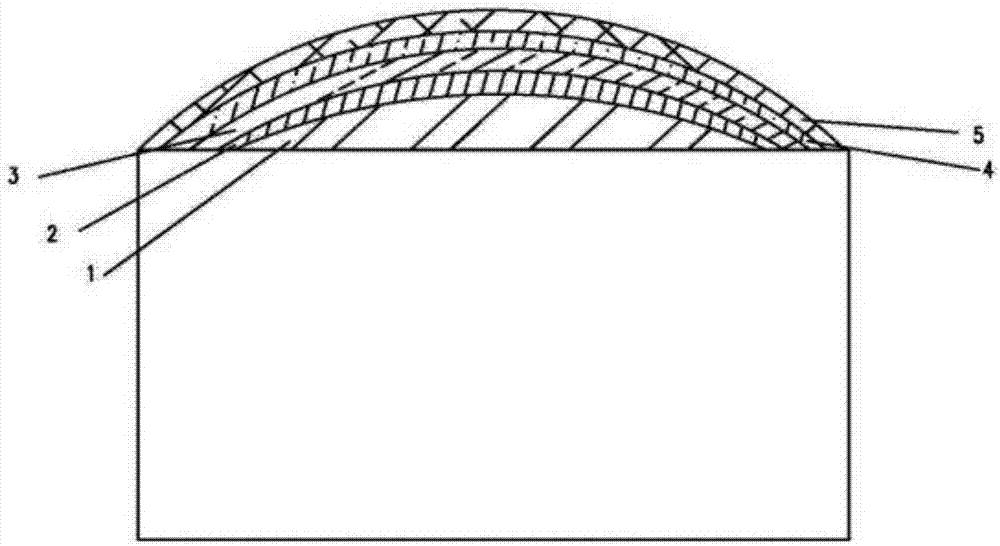

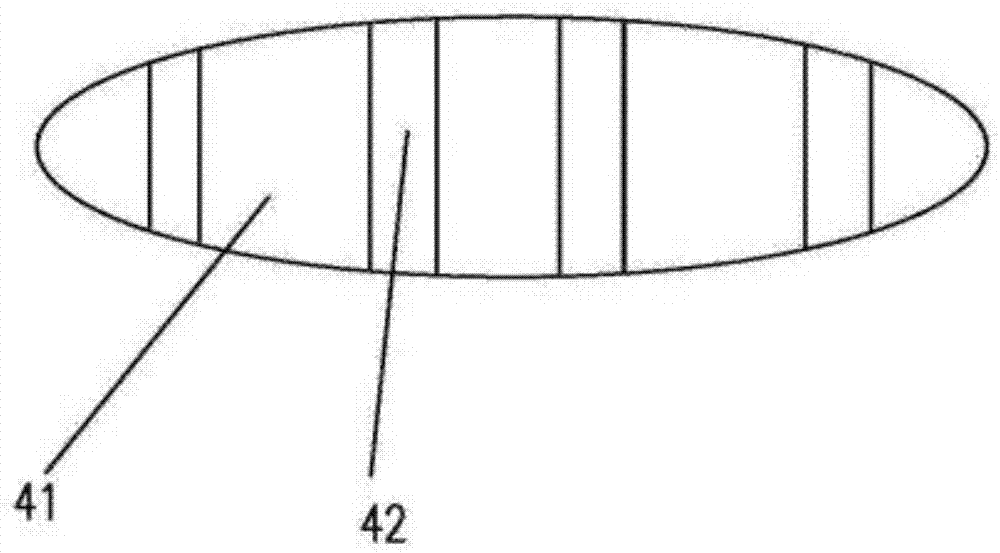

[0022] refer to Figure 1 to Figure 3 As shown, the roof of an oil and gas storage tank for raw material storage tanks of new energy chemical fiber products includes an arc-shaped inner lining layer 1, a surface coating layer 2, a putty layer 3, and a light-cured coating layer arranged in sequence from the inner lining layer 1 to the outside. Fiber reinforced composite sheet layer 4, sealing coating 5;

[0023] The inner lining layer 1 is coated with a polyethylene resin layer, the surface coating 2 and the sealing coating 5 are nano-composite emulsions, and the putty layer 3 is prepared by adding a certain proportion of curing agent to the nano-composite emulsion and then adding quartz sand. The number of cladding layers shall be at least one layer, and the thickness of a single layer shall not exceed 10mm;

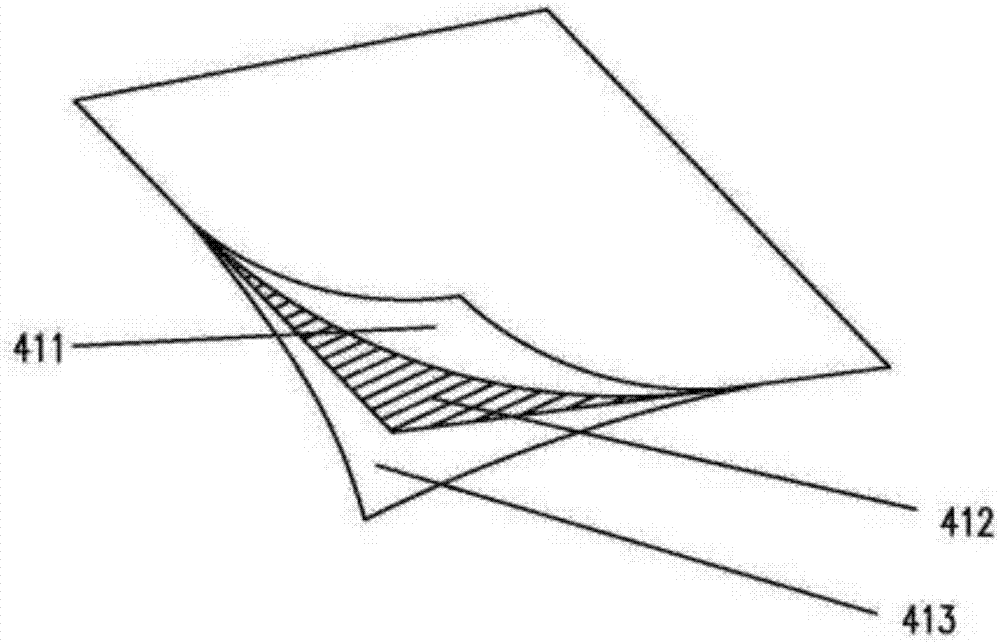

[0024] The light-cured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com