Clean production method of nitrochlorobenzene

A technology for nitrochlorobenzene and a production method, which is applied in chemical instruments and methods, nitro compound preparation, chemical recovery and other directions, can solve the problems of long production cycle, difficult implementation, insufficient purity, etc., and achieves saving synthesis costs and optimizing processes. Design, improve the effect of economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

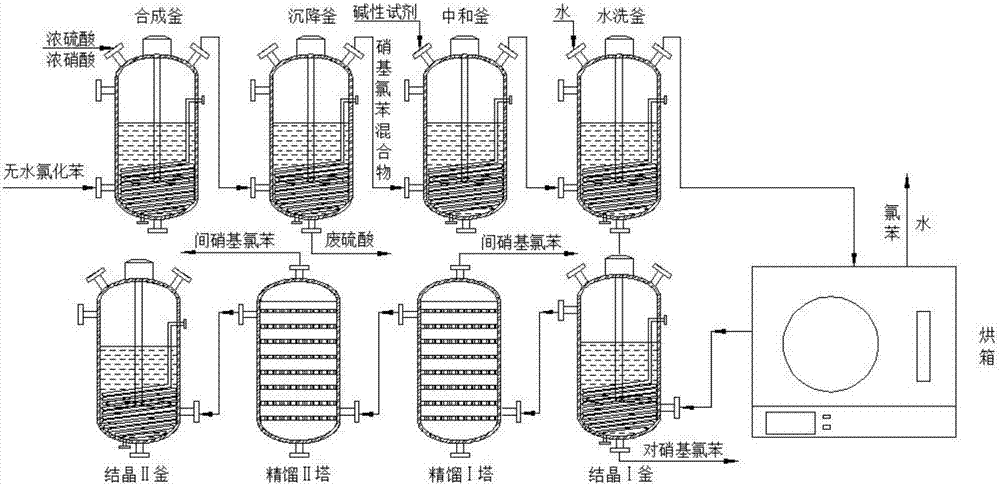

[0028] see figure 1 Shown, the technical scheme that the present invention adopts is: a kind of clean production method of nitrochlorobenzene, the concrete of described production method comprises the following steps:

[0029] (1).Nitration: Add anhydrous chlorinated benzene, sulfuric acid solution and nitric acid solution to the interior of the synthesis kettle, set the reaction temperature, stirring rate and reaction pressure inside the synthesis kettle, start the agitator to react, and the reaction generates nitro Chlorobenzene mixture;

[0030] (2). Sedimentation and separation: Add the nitrochlorobenzene mixture after the reaction in the synthesis tank and the waste sulfuric acid produced by nitration to the inside of the settling tank, and after settling in the settling tank for a period of time, separate the waste sulfuric acid and the nitrochlorobenzene mixture ;

[0031] (3). Neutralization: Add the acidic nitrochlorobenzene mixture separated from the settling tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com