Protein adsorption-resistant capillary column and preparation method thereof

An anti-protein adsorption and capillary column technology, which is applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problems of high toxicity in the production process, complicated preparation process, and low production efficiency, and achieve excellent anti-corrosion Protein adsorption performance, simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

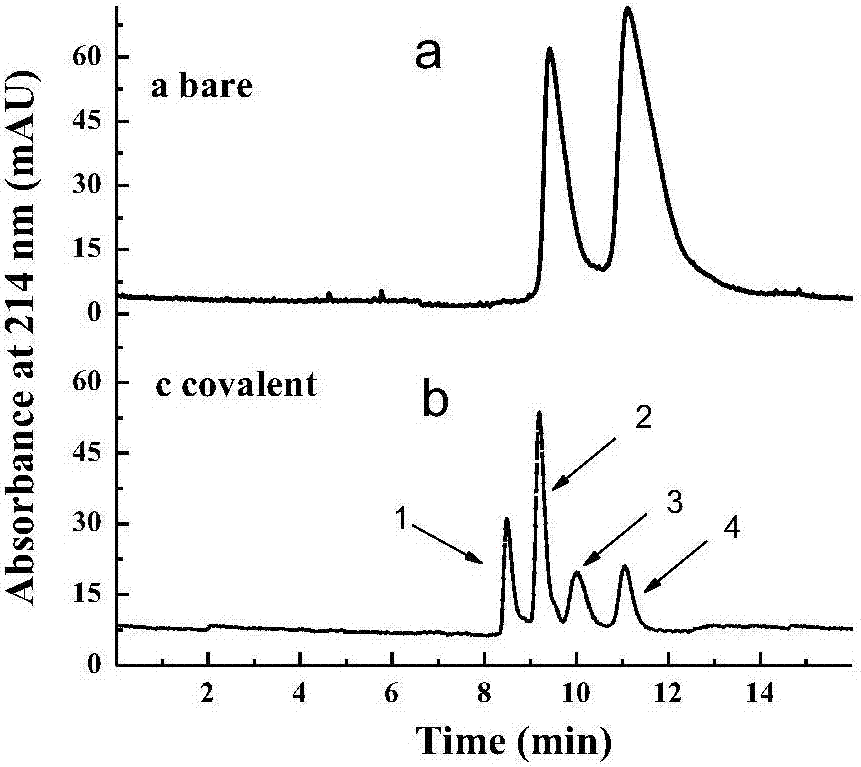

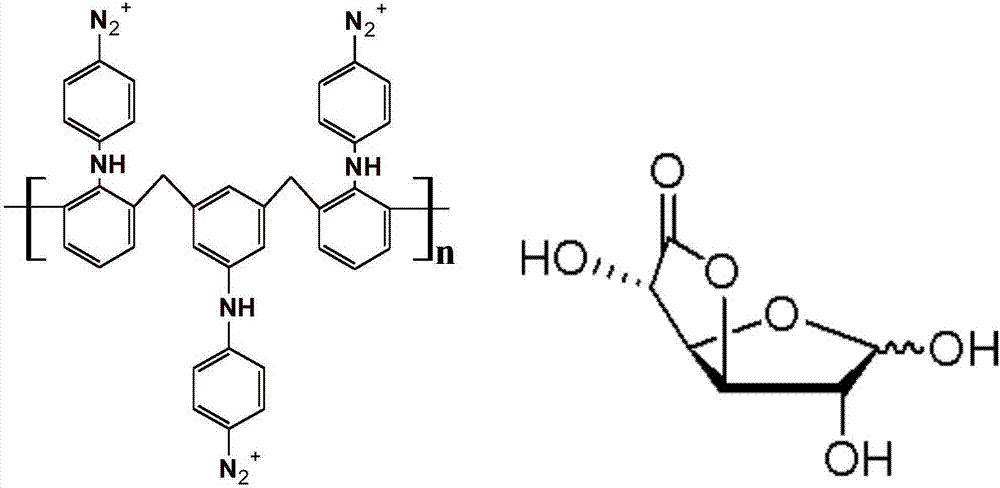

[0029] The preparation method of the above-mentioned capillary column resistant to protein adsorption uses diazo resin and glucuronolactone to self-assemble layer by layer on the inner wall of the quartz capillary column through electrostatic interaction, and undergoes photocuring and cross-linking reaction through ultraviolet light, so that the original The hydrogen bonds are converted to covalent bonds, resulting in a stable covalently bonded coating on the inner wall of the quartz capillary. Specifically, the preparation method comprises the following steps:

[0030] S1, the concentration is 0.1-100mg·ml -1 Photosensitive diazo resin solution, water, concentration 0.1-100mg·ml -1 The glucuronolactone aqueous solution and water are slowly injected into the capillary successively; the mass ratio of the photosensitive diazo resin and the glucuronolactone is 1:(1-1.5);

[0031] The concentration of the above-mentioned diazo resin and glucuronolactone aqueous solution is 0.1mg...

Embodiment 1

[0043] This embodiment provides an anti-protein adsorption capillary column, the inner wall of the capillary is modified with an anti-protein covalent bonding coating, and the anti-protein covalent bonding coating is composed of photosensitive diazo resin and glucosaldehyde Acid lactone is formed by photocuring and crosslinking reaction by ultraviolet light irradiation, and the anti-protein covalent bonding coating includes a layer of photosensitive diazo resin and a layer of glucuronolactone layer, and the anti-protein covalent bonding The coating is approximately 1.8 nm thick.

[0044] The preparation method of the above-mentioned anti-protein adsorption capillary column comprises the following steps:

[0045] S0, capillary internal activation pretreatment

[0046] successively with a concentration of 0.1mol·L -1 Sodium hydroxide solution, distilled water, the concentration is 0.1mol L -1 Flush the capillary with hydrochloric acid solution, distilled water and methanol fo...

Embodiment 2

[0051] This embodiment provides an anti-protein adsorption capillary column, the inner wall of the capillary is modified with 7 layers of anti-protein adsorption covalent bonding coating, and the anti-protein covalent bonding coating is composed of photosensitive diazo resin and Glucuronolactone is formed by photocuring and crosslinking reaction by ultraviolet light irradiation, the photosensitive diazo resin and the glucuronolactone layers are alternately arranged, and each layer of the anti-protein covalent bonding coating A layer of anti-protein covalently bonded coating with a thickness of 1.1-1.8nm.

[0052] The preparation method of the above-mentioned anti-protein adsorption capillary column comprises the following steps:

[0053] S0, capillary internal activation pretreatment

[0054] successively with a concentration of 0.09mol·L -1 Sodium hydroxide solution, distilled water, the concentration is 0.11mol L -1 Flush the capillary with hydrochloric acid solution, dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com