Preparation method for vacuum sintering of YAG-based crystalline ceramic under existence of non-silicon additive

A technology for transparent ceramics and vacuum sintering, which is applied in the field of vacuum sintered yttrium aluminum garnet-based transparent ceramics, achieving obvious effects, solving the effects of large grain size and reasonable grain size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

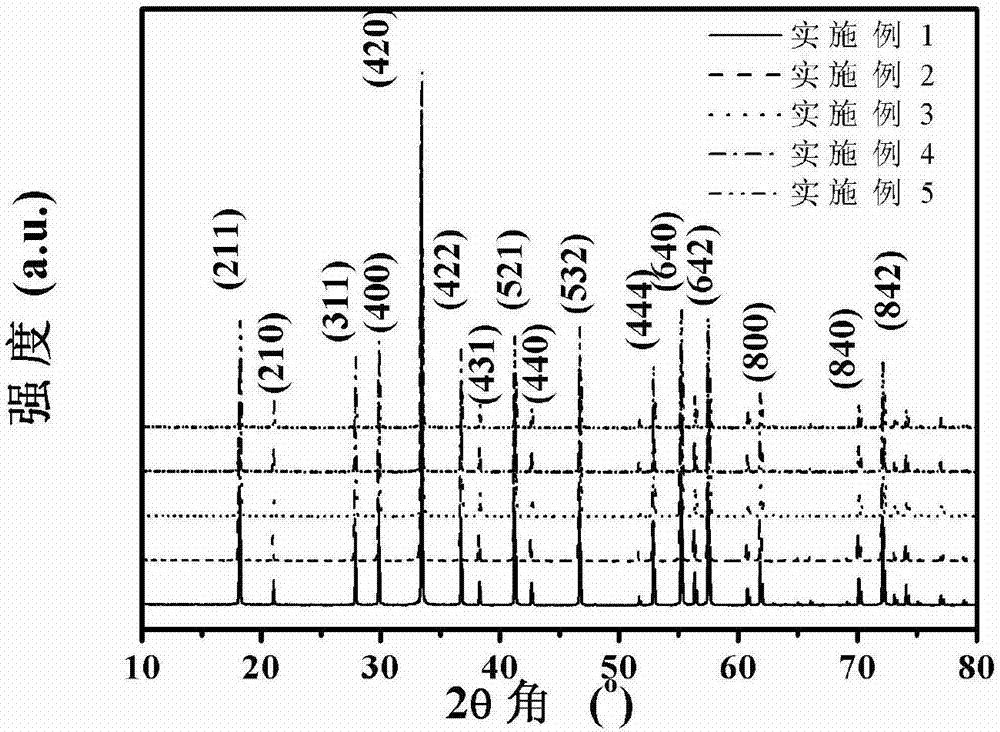

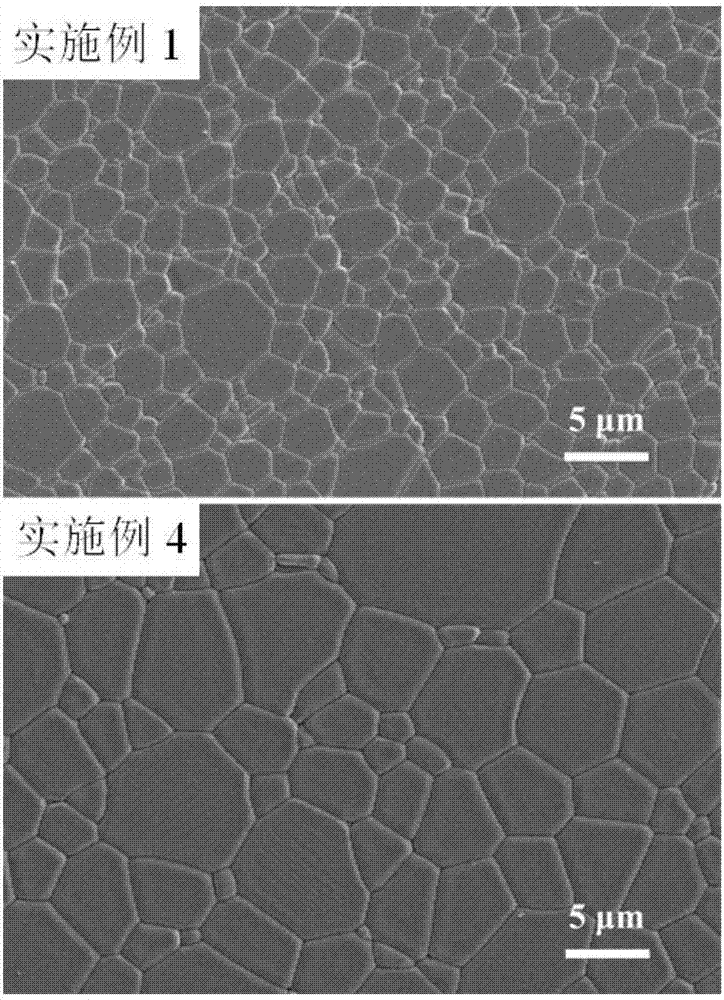

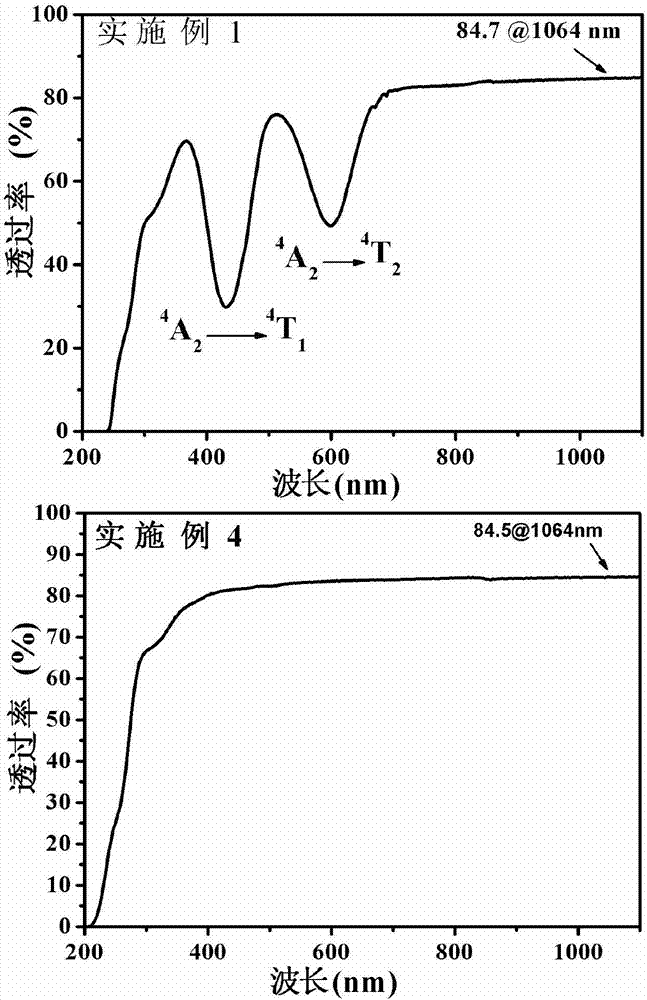

Embodiment 1

[0037] ①The commercially available concentration of 99.999% Y 2 o 3 ,99.999% Al 2 o 3 and 99.999% Cr 2 o 3 press Y 3 (Cr 0.003 Al 0.997 ) 5 o 12 After weighing the stoichiometric ratio, place it in a ball mill jar, then add 0.20mol% La 2 o 3 and 0.20mol% MgO as a sintering aid, 0.3wt% DS005 as a dispersant, adding absolute ethanol to configure a slurry with a solid content of 40%.

[0038] ②Put the slurry obtained in step ① on a planetary ball mill and mix for 10 hours at a speed of 220r / min. Dry the slurry after ball milling at 50°C for 36h, and sieve the dried precursor with 80 Sieve through a mesh sieve 3 times.

[0039] ③The sieved powder obtained in step ② was placed in a stainless steel mold, and pressed into a disc by 60 MPa dry pressing, and then subjected to 180 MPa cold isostatic pressing to obtain a biscuit, and the holding time was 15 minutes. The green body was calcined at 700°C in an air atmosphere, kept for 6 hours, and cooled to 20°C. The heating ...

Embodiment 2

[0042] ①The commercially available concentration of 99.99% Y 2 o 3 ,99.99% Al 2 o 3 ,99.99% Nd 2 o 3 and 99.99 Cr 2 o 3 Press (Nd 0.01 Y 0.99 ) 3 (Cr 0.001 Al 0.999 ) 5 o 12 After the stoichiometric ratio was weighed, it was placed in a ball mill jar, and then 0.02mol% La was added 2 o 3 and 0.03mol MgO as a sintering aid, 1wt% DS005 as a dispersant, adding absolute ethanol to configure a slurry with a solid content of 30%.

[0043] ②Put the slurry obtained in step ① on a planetary ball mill for ball milling and mixing for 6 hours at a speed of 280r / min. After the ball milling, dry the slurry at 120°C for 10 hours, and sieve the dried precursor with a 50 Sieve through a mesh sieve 4 times.

[0044] ③The sieved powder obtained in step ② was placed in a stainless steel mold, and pressed into a disc by 100 MPa dry pressing, and then subjected to 100 MPa cold isostatic pressing to obtain a biscuit, and the holding time was 20 minutes. The green body was calcined a...

Embodiment 3

[0047] ①The commercially available concentration of 99.999% Y 2 o 3 ,99.999% Al 2 o 3 and 99.999% Yb 2 o 3 Press (Yb 0.3 Y 0.7 ) 3 Al 5 o 12 After weighing the stoichiometric ratio, place it in a ball mill jar, then add 0.25mol% La 2 o 3 and 0.25mol% MgO as a sintering aid, 0.1wt% DS005 as a dispersant, adding absolute ethanol to configure a slurry with a solid content of 65%.

[0048] ②Put the slurry obtained in step ① on a planetary ball mill and mix for 18 hours at a speed of 120r / min. After the ball milling, dry the slurry at 40°C for 48h, and sieve the dried precursor, using 200 Sieve through a mesh sieve once.

[0049] ③The sieved powder obtained in step ② was placed in a stainless steel mold, pressed into a disc by 40Mpa dry pressing, and then subjected to 250MPa cold isostatic pressing to obtain a biscuit, and the holding time was 5min. The green body is calcined at 1000°C in an air atmosphere, kept for 2 hours, and cooled to 40°C. The heating rate of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com