Method for preparing ethylbenzene by utilizing light alkanes

A technology for low-carbon alkanes and ethylbenzene, which is applied in the field of preparing ethylbenzene, can solve the problems of difficulty in ethylene transportation, improve the entry threshold of the ethylbenzene market, etc., and achieve the effects of flexible device design scale, compact production space design, and efficient utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

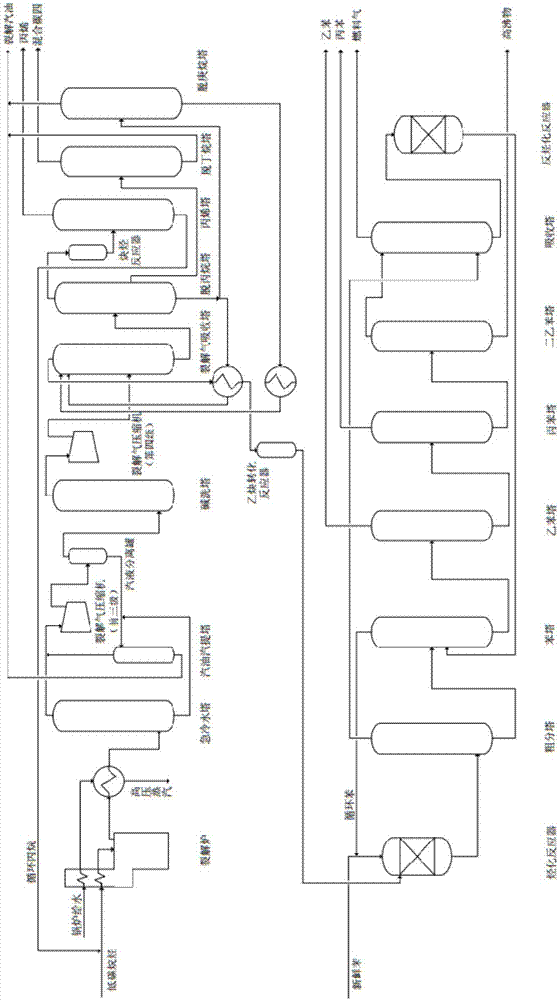

Image

Examples

Embodiment 1

[0045] Using the low-value product saturated liquefied gas LPG in the refinery as raw material to produce 100,000 tons / year of ethylbenzene.

[0046] The composition of the raw materials used in this embodiment is shown in Table 1 below:

[0047] Table 1

[0048] composition

[0049] The raw material consumption of present embodiment is as shown in table 2 below:

[0050] Table 2

[0051] raw material

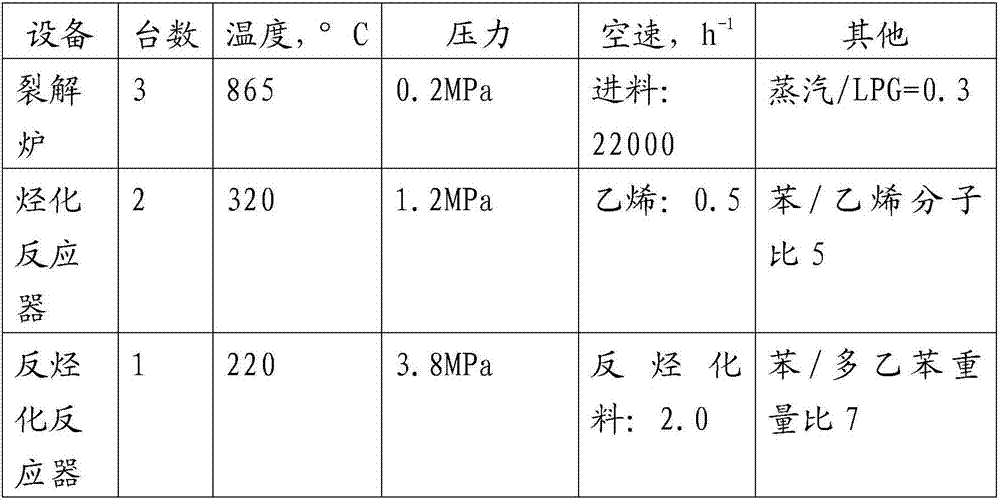

[0052] The main processing conditions of the present embodiment are shown in table 3 below:

[0053] table 3

[0054]

[0055] The technology that present embodiment produces ethylbenzene is as follows:

[0056] (1) cracking unit:

[0057] The normal temperature saturated liquefied gas with a pressure of about 1.5MPa (in the continuous production process, the saturated liquefied gas can be combined with the circulating propane produced in the subsequent steps) is preheated by quenching water and then enters the vaporizer, and is fully vaporized befor...

Embodiment 2

[0088] In this embodiment, n-butane is selected as raw material to produce 300,000 tons / year of ethylbenzene. For the process of this embodiment, refer to Embodiment 1, and details are not repeated here.

[0089] The composition of the raw materials used in this embodiment is shown in Table 5:

[0090] table 5

[0091] composition

wt%

n-butane

100

total

100

[0092] The raw material consumption of this embodiment is shown in Table 6.

[0093] Table 6

[0094] raw material

KTA

kg / hr

n-butane

195

24392

219

27381

total

414

51772

[0095] The product distribution of this embodiment is shown in Table 7.

[0096] Table 7

[0097] product

KTA

kg / hr

58

7227

Propylene

36

4442

mixed carbon tetraolefins

11

1323

of which butadiene

7

866

6

768

300...

Embodiment 3

[0104] In this embodiment, ethane is selected as a raw material to produce 600,000 tons / year of ethylbenzene. For the process of this embodiment, refer to Embodiment 1, and details are not repeated here.

[0105] The composition of raw materials in this example is shown in Table 9.

[0106] Table 9

[0107] composition

wt%

1.26

ethane

93.77

propane

4.97

total

100

[0108] See Table 10 for the consumption of raw materials in this embodiment.

[0109] Table 10

[0110] raw material

KTA

kg / hr

ethane

311

38860

benzene

448

55946

total

758

94806

[0111] The product distribution of this embodiment is shown in Table 11.

[0112] Table 11

[0113]

[0114] Propane / butane recycle, and recovery of benzene from pyrolysis gasoline are considered in Table 11.

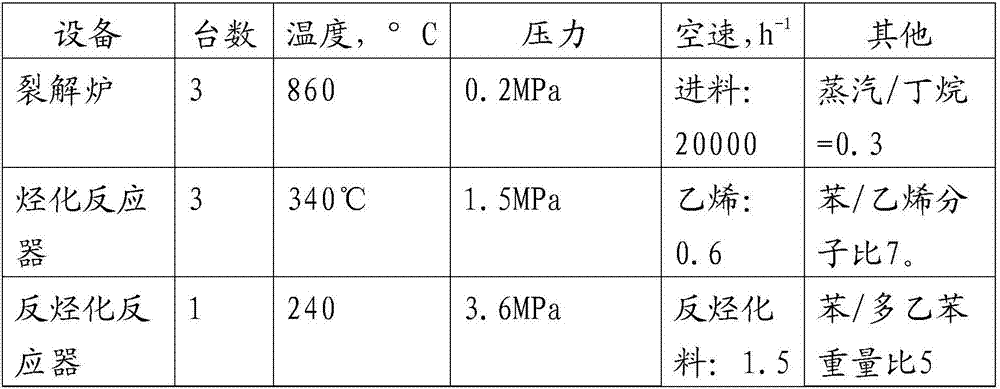

[0115] The main process conditions of this embodiment are shown in Table 12.

[0116] Table 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com