Perovskite solar cell and preparation method thereof

A solar cell and perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low photoelectric conversion efficiency and insufficient stability of solar cells, so as to improve hole transport capacity and photoelectric conversion efficiency , the effect of improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

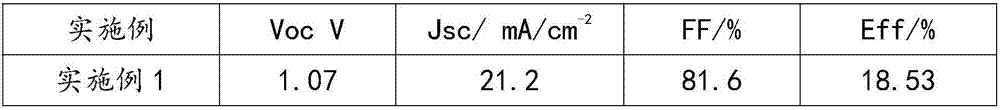

Embodiment 1

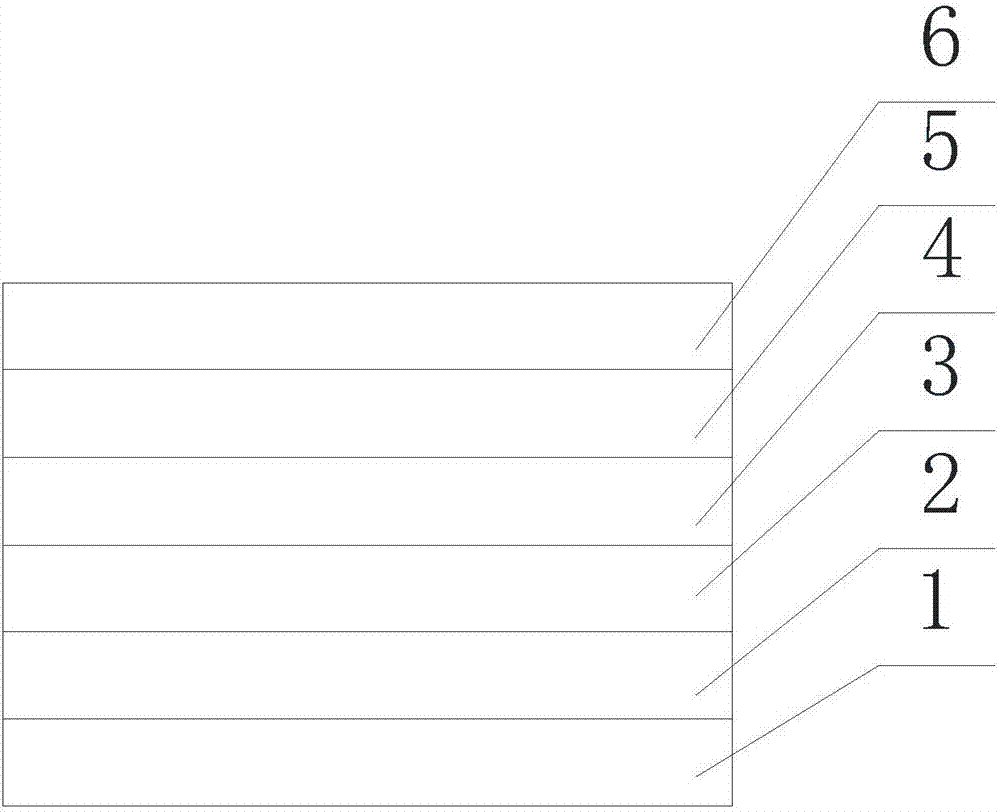

[0039] A perovskite solar cell, such as figure 1 shown, comprising sequentially conductive glass substrate 1, NiO x Hole transport layer 2, perovskite absorption layer 3, electron transport layer 4, buffer layer 5, metal electrode layer 6, conductive glass substrate is selected as FTO conductive glass, and its specific preparation steps are as follows:

[0040] A. Treatment of FTO conductive glass substrate 1: The square resistance of FTO in FTO conductive glass is 14Ω, and the transmittance is 90%. After the substrate is cleaned, put the conductive side up into the UV ozone machine, and set the processing time For 5 minutes, turn on the ultraviolet lamp, carry out ultraviolet and ozone treatment to it, and take it out for later use after completion;

[0041] B. NiO xPreparation of the hole transport layer 2: dissolving yttrium oxide in nitric acid to prepare 0.1mol / L yttrium nitrate solution, dissolving magnesium nitrate and nickel nitrate in deionized water to prepare 0.1m...

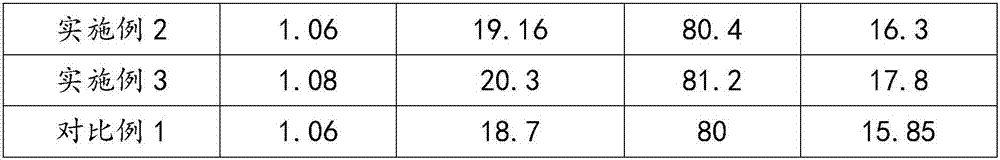

Embodiment 2

[0047] A perovskite solar cell, such as figure 1 As shown, including sequentially 1, conductive glass substrate, 2, NiO x Hole transport layer, 3, perovskite absorption layer, 4, electron transport layer, 5, buffer layer, 6, metal electrode layer, conductive glass substrate is selected as FTO conductive glass and its specific preparation steps are as follows:

[0048] A. Treatment of FTO conductive glass substrate: The square resistance of FTO in the FTO conductive glass substrate is 14Ω, and the transmittance is 90%. After the substrate is cleaned, put the conductive surface upward into the ultraviolet ozone machine, set The treatment time is 5 minutes, turn on the ultraviolet lamp, carry out ultraviolet and ozone treatment on it, and take it out for later use after completion;

[0049] B. NiO x Preparation of the hole transport layer: dissolving yttrium oxide in nitric acid to prepare 0.1mol / L yttrium nitrate solution, dissolving magnesium nitrate and nickel nitrate in dei...

Embodiment 3

[0055] A perovskite solar cell, as shown in the figure, including sequentially 1, a conductive glass substrate, 2, NiO x Hole transport layer, 3, perovskite absorption layer, 4, electron transport layer, 5, buffer layer, 6, metal electrode layer, conductive glass substrate is selected as its specific preparation steps of ITO conductive glass as follows:

[0056] A. Treatment of ITO conductive glass substrate: The square resistance of ITO in the ITO conductive glass substrate is 8Ω, and the transmittance is 86%. The time is 5min, turn on the ultraviolet lamp, carry out ultraviolet ozone treatment to it, take out after completion and set aside; B, NiO x Preparation of the hole transport layer: dissolving yttrium oxide in nitric acid to prepare 0.1mol / L yttrium nitrate solution, dissolving copper nitrate and nickel nitrate in deionized water to prepare 0.1mol / L copper nitrate and nickel nitrate solution , and mixed with yttrium nitrate solution, adding sodium hydroxide solution,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com