Automotive aqueous polyurethane coating and preparation method thereof

A technology of water-based polyurethane and solvent-free polyurethane, which is applied in the direction of anti-fouling/underwater coatings, paints containing biocide, etc., can solve problems such as difficult access, no attention to product environmental protection issues, difficult emulsification, etc., and achieve improved hydrophilicity , good emulsifying effect, excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

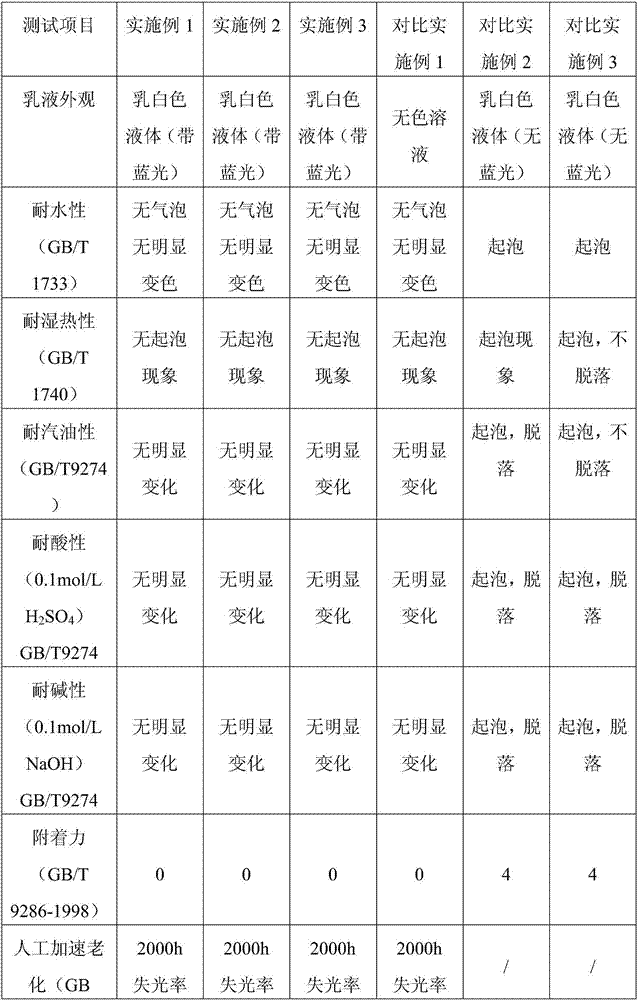

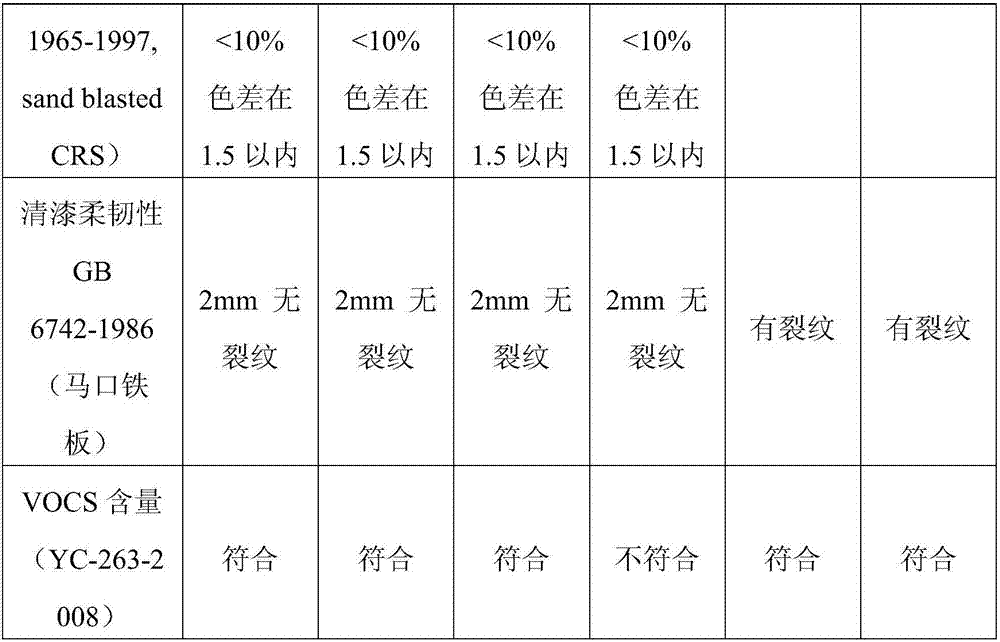

Embodiment 1

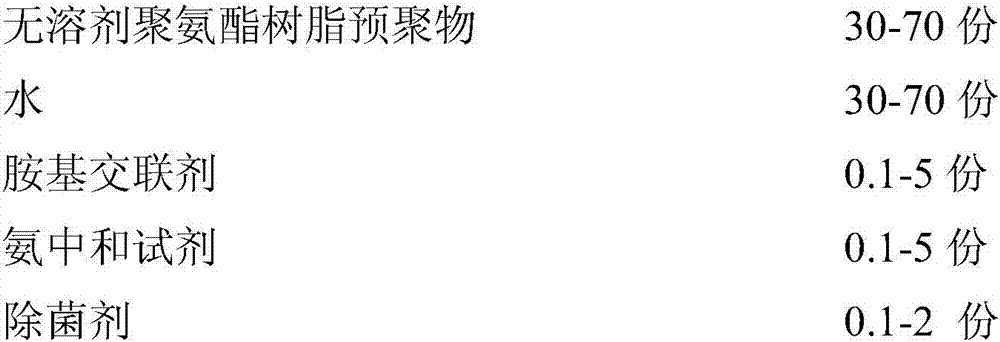

[0032] A water-based polyurethane coating for vehicles, comprising the following components: a solvent-free polyurethane resin prepolymer as a main body; water as a dispersion medium; an amine-based crosslinking agent for crosslinking water-based polyurethane, which is used in this embodiment Aliphatic amine crosslinker.

[0033] Among them, the solvent-free polyurethane resin prepolymer is obtained by prepolymerizing isophorone diisocyanate, linear aliphatic polycarbonate polyester polyol and dihydroxymethylpropionic acid as raw materials.

[0034] In the present embodiment, the preparation method of water-based polyurethane paint for vehicles specifically includes the following steps:

[0035] (1) Weigh 20 parts of linear aliphatic polycarbonate polyester polyols through dehydration and drop into a reaction kettle with a thermometer, a condensation device and a mechanical stirring device, and dropwise add 3 parts of bishydroxymethyl propionic acid Solvent and 10 parts of is...

Embodiment 2

[0040] The preparation method of water-based polyurethane paint for automobiles specifically comprises the steps:

[0041] (1) Weigh 25 parts of linear aliphatic polycarbonate polyester polyols through dehydration and drop into a reaction kettle with a thermometer, a condensation device and a mechanical stirring device, and dropwise add 3.5 parts of bishydroxymethyl propionic acid Solvent and 13 parts of isophorone diisocyanate, the mixed solution was reacted within a temperature range of 75°C for 4 hours, and the NCO mass content in the obtained prepolymer was 1.8%;

[0042] (2) Lower the temperature to about 40°C, add 3.5 parts of ammonia neutralizing reagent, stir for 30 minutes, and finally add 50 parts of deionized water under high-speed shear at a speed greater than 2000rpm to emulsify, disperse for 25 minutes, and obtain slightly blue light water-based emulsion;

[0043] (3) remove solvent, add 1.5 parts of amine-based cross-linking agent;

[0044] (4) Add 0.5 part of...

Embodiment 3

[0046] The preparation method of water-based polyurethane paint for automobiles specifically comprises the steps:

[0047](1) Weigh 30 parts of linear aliphatic polycarbonate polyester polyols through dehydration and drop into a reaction kettle with a thermometer, a condensation device and a mechanical stirring device, and dropwise add 4 parts of bishydroxymethyl propionic acid Solvent and 16 parts of isophorone diisocyanate, the mixed solution was reacted within the temperature range of 90° C. for 4 hours, and the NCO mass content in the obtained prepolymer was 2.0%;

[0048] (2) Lower the temperature to about 30°C, add 4 parts of ammonia neutralizing reagent, stir for 40 minutes, and finally add 60 parts of deionized water under high-speed shear at a speed greater than 2000rpm to emulsify, disperse for 30 minutes, and obtain slightly blue light water-based emulsion;

[0049] (3) remove solvent, add 2 parts of amine-based cross-linking agent;

[0050] (4) Finally, add 1 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com