Single oriented iridium oxide nano array preparation and membrane electrode construction method

A nano-array and nano-tube array technology, which is applied in the field of single-orientation iridium oxide nano-array preparation and membrane electrode construction, can solve the problems of cumbersome operation and achieve the effect of reducing ring damage and retaining the shape of nano-array

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

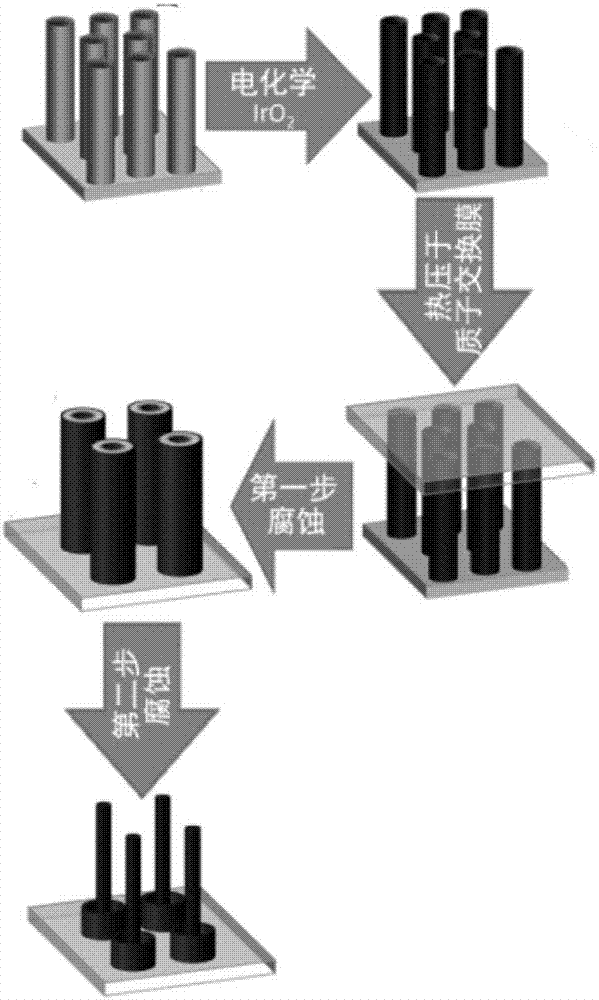

[0040] A method for preparing an iridium oxide nano-array and a membrane electrode, comprising the steps of:

[0041] Step (1): Preparation of titanium dioxide nanotube arrays by anodic corrosion method

[0042] A titanium sheet with a size of 35mm*10mm and a thickness of 0.1mm was pickled in hydrochloric acid with a mass fraction of 10% at 80°C for 10 minutes, and then rinsed several times with deionized water. The titanium sheets after pickling were polished with No. 600, No. 1000, No. 2000 and No. 3000 metallographic sandpaper in sequence, and ultrasonically cleaned in absolute ethanol and deionized water for 10 minutes in sequence.

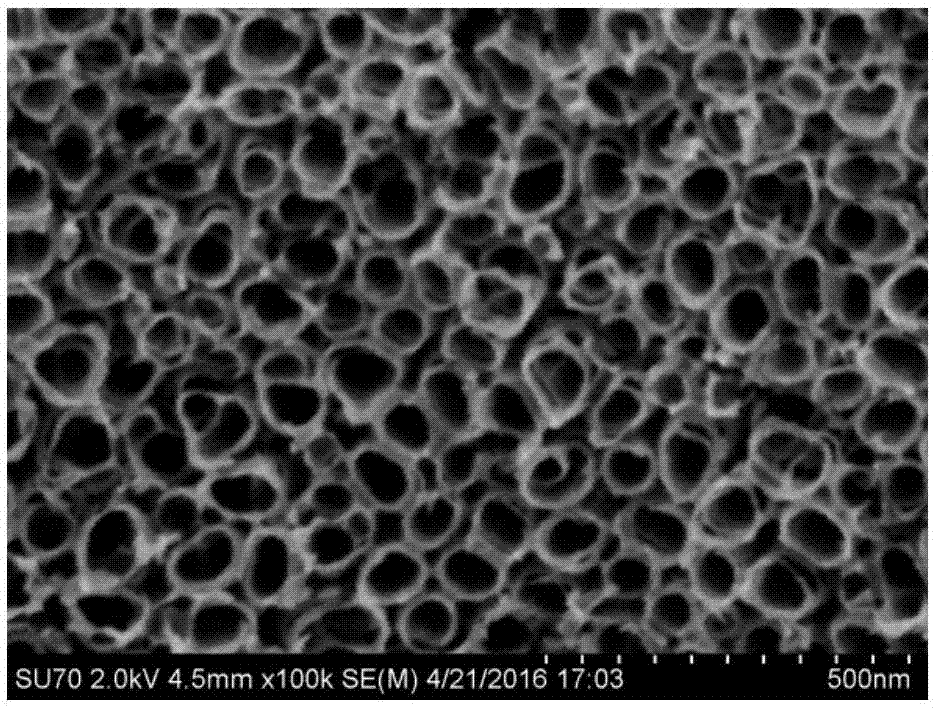

[0043] The polished and cleaned titanium sheet is used as the positive electrode, the platinum sheet is used as the negative electrode, and 25ml of hydrofluoric acid aqueous solution with a mass fraction of 0.3% is used as the electrolyte, and a voltage of 10V is applied to electrochemically oxidize for 1 hour to obtain a titanium dioxide nano...

Embodiment 2

[0054] A method for preparing an iridium oxide nano-array and a membrane electrode, comprising the steps of:

[0055] Step (1) Preparation of titanium dioxide nanotube arrays by anodic corrosion method

[0056] A titanium sheet with a size of 35mm*10mm and a thickness of 0.2mm was pickled in hydrochloric acid with a mass fraction of 10% at 80°C for 10 minutes, and then rinsed several times with deionized water. The titanium sheets after pickling were polished with No. 600, No. 1000, No. 2000 and No. 3000 metallographic sandpaper in sequence, and ultrasonically cleaned in absolute ethanol and deionized water for 10 minutes in sequence.

[0057] The polished and cleaned titanium sheet is used as the positive electrode, the platinum sheet is used as the negative electrode, and 25ml of hydrofluoric acid aqueous solution with a mass fraction of 0.1% is used as the electrolyte, and a voltage of 20V is applied to electrochemically oxidize for 1 hour to obtain a titanium dioxide nanot...

Embodiment 3

[0066]A method for preparing an iridium oxide nano-array and a membrane electrode, comprising the steps of:

[0067] Step (1) Preparation of titanium dioxide nanotube arrays by anodic corrosion method

[0068] A titanium sheet with a size of 35mm*10mm and a thickness of 0.5mm was pickled in hydrochloric acid with a mass fraction of 10% at 80°C for 10 minutes, and then rinsed several times with deionized water. The titanium sheets after pickling were polished with No. 600, No. 1000, No. 2000 and No. 3000 metallographic sandpaper in sequence, and ultrasonically cleaned in absolute ethanol and deionized water for 10 minutes in sequence.

[0069] The polished and cleaned titanium sheet was used as the positive electrode, the platinum sheet was used as the negative electrode, and 25ml of hydrofluoric acid aqueous solution with a mass fraction of 0.5% was used as the electrolyte, and a voltage of 30V was applied to electrochemically oxidize for 1 hour to obtain a titanium dioxide na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com