Packaging product and packaging method of degradable aliphatic polyester or its medical products

A technology for degrading fat and packaging method, applied in the medical field, can solve problems such as affecting the performance of degradable aliphatic polyester raw materials and their products, large hydrolysis of raw materials in melt processing, difficulty in ensuring the stability of raw materials, etc. Risk, reduce the risk of failure, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

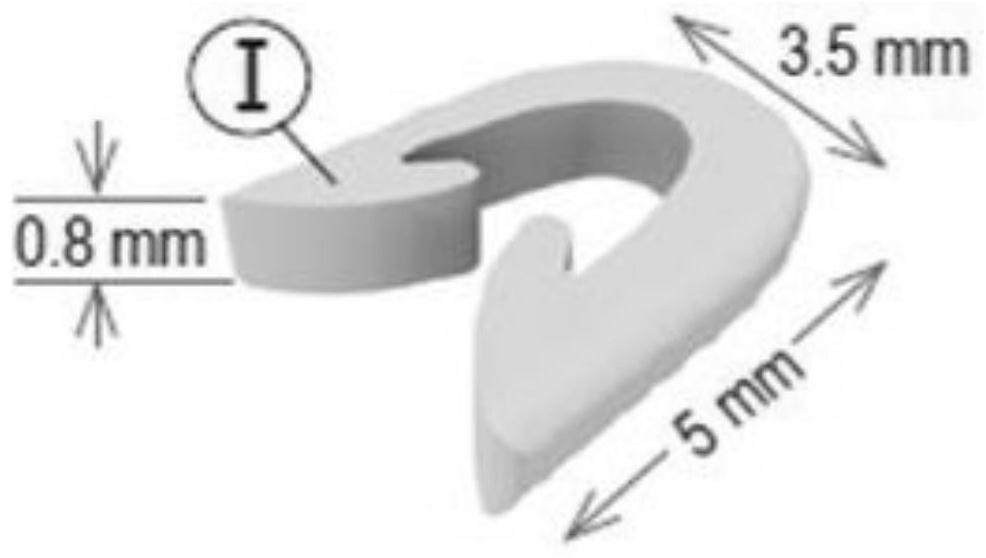

[0026]300g of degradable aliphatic polyester raw material and 4A molecular sieve of a certain quality are placed in a 4-layer composite aluminum foil bag (PET / AL / PA / PE) and packaged under normal pressure, and the thickness of the aluminum foil layer is 20 microns; wherein, in embodiment 1, simultaneously Compare the drying effects of the following five degradable aliphatic polyester raw materials: A, L-lactide, glycolide copolymer 8218 (the molar ratio of L-lactide and glycolide is 82:18, referred to as PLGA8218, below Same); B, L-lactide, glycolide copolymer 6040 (PLGA6040); C, L-lactide, trimethylene carbonate lactone copolymer 7030 (PLTMC7030); D, polyglycolide (PGA ); E, L-polylactide (PLLA); the above five degradable aliphatic polyester raw materials are pellets with a diameter of 3±2mm; the above-mentioned packaged products are placed in a relatively closed plastic box at room temperature (25°C) Preserve; after a period of time, measure the moisture content in the packag...

Embodiment 2

[0028] The difference between Example 2 and Example 1 is that 4A molecular sieve is replaced by 3A molecular sieve.

Embodiment 3

[0030] The difference between Example 3 and Example 1 is that the 4A molecular sieve is replaced by BASF KC Trockenperlen silica gel desiccant.

[0031] The test result of table 2 embodiment 1-3 degradable aliphatic polyester raw material

[0032]

[0033]

[0034] As can be seen from Table 2, compared with no desiccant, the water content in the packaged product after adding a desiccant is low; after packaging the same degradable aliphatic polyester with the same desiccant, The greater the amount or the longer the packaging drying / storage time, the lower the moisture content in the packaging product, that is, the better the drying effect, and after 7 days of packaging drying / storage, the moisture content has met the requirements (less than 500ppm); from degradable Comparing the initial intrinsic viscosity of the aliphatic polyester raw material and the intrinsic viscosity after 180 days, it can be seen that the intrinsic viscosity values of the two are equivalent, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com