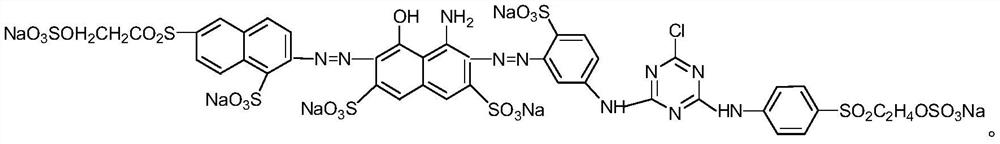

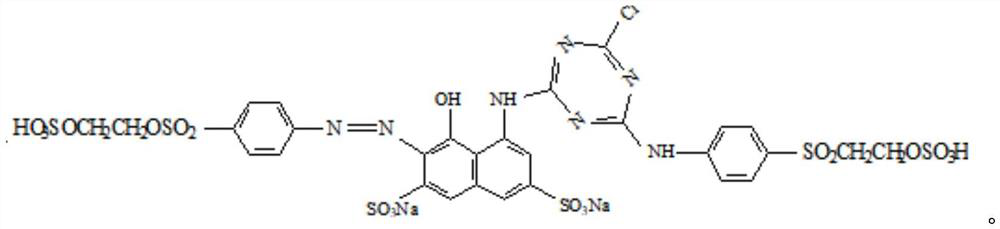

A kind of preparation method and application of three reactive group blue dyes

A technology of blue dye and three reactive groups, applied in the field of reactive dye preparation and application, can solve the problems of low diazonium salt conversion rate, low acid azo liquid phase value, affecting dye quality and application performance, etc., and achieve dye yield And the effect of quality improvement, high color fastness, dye uptake and color fastness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

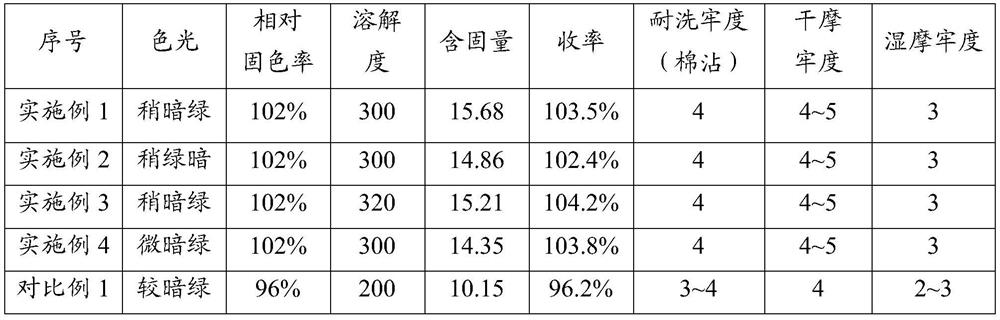

Examples

Embodiment 1

[0040] (1) One condensation

[0041] Weigh 20g of cyanuric chloride and 0.3g of dispersant MF in a 1000mL beaker, beat in an ice bath for 0.5h, add 30.45g of para-ester dry powder in percent, add a small amount of dispersant MF and crushed ice, continue mixing and beating for 1 hour, After the beating is completed, the pH is about 1.0, and the pH of the material is adjusted to 2.8-3.2 with a mixed alkali for about 1 hour, and the temperature is kept at 4-9°C, and the pH is 2.8-3.2 to react to the end.

[0042] (2) Secondary condensation

[0043] Once the end point is reached, add 22.3% solid bismuth and sodium bicarbonate to adjust the pH to 5-5.5, raise the temperature to 20-25°C, and keep the pH at 5-5.5 for 3-4 hours until the end point is reached.

[0044] (3) Diazotization reaction of dicondensates

[0045] After the end point of the second shrinkage is reached, cool down in an ice bath to below 5°C, add 1 gram of dispersant NNO, stir for 5 minutes, add hydrochloric aci...

Embodiment 2

[0053] (1) One condensation

[0054] Weigh 20g of cyanuric chloride and 0.3g of dispersant MF in a 1000mL beaker, beat in an ice bath for 0.5h, add 30.6g of para-ester dry powder in percent, add a small amount of dispersant MF and crushed ice, continue mixing and beating for 1 hour, After the beating is completed, the pH is about 1.0, and the pH of the material is adjusted to 2.8-3.2 with a mixed alkali for about 1 hour, and the temperature is kept at 4-9°C, and the pH is 2.8-3.2 to react to the end.

[0055] (2) Secondary condensation

[0056] Once the end point is reached, add 22.3% solid bismuth and sodium bicarbonate to adjust the pH to 5-5.5, raise the temperature to 20-25°C, and keep the pH at 5-5.5 for 3-4 hours until the end point is reached.

[0057] (3) Diazotization reaction of dicondensates

[0058] After the end point of the second shrinkage is reached, cool down in an ice bath to below 5°C, add 1 gram of dispersant NNO, stir for 5 minutes, add hydrochloric acid...

Embodiment 3

[0066] (1) One condensation

[0067] Weigh 20g of cyanuric chloride and 0.3g of dispersant MF in a 1000mL beaker, beat in an ice bath for 0.5h, add 30.45g of para-ester dry powder in percent, add a small amount of dispersant MF and crushed ice, continue mixing and beating for 1 hour, After the beating is completed, the pH is about 1.0, and the pH of the material is adjusted to 2.8-3.2 with a mixed alkali for about 1 hour, and the temperature is kept at 4-9°C, and the pH is 2.8-3.2 to react to the end.

[0068] (2) Secondary condensation

[0069] Once the end point is reached, add 22.3% solid bismuth and sodium bicarbonate to adjust the pH to 5-5.5, raise the temperature to 20-25°C, and keep the pH 5-5.5 for 3-4 hours until the end point is reached.

[0070] (3) Diazotization reaction of dicondensates

[0071] After the end point of the second shrinkage is reached, cool down in an ice bath to below 5°C, add 1.4 g of dispersant NNO, stir for 5 minutes, add hydrochloric acid an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com