An ultra-high temperature organic cross-linked fracturing fluid system

A fracturing fluid and ultra-high temperature technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of short cross-linking time, unfavorable control of fracture height, difficulty in on-site fluid dispensing, etc., and achieve long cross-linking time. , reduce the risk of hydrolysis, and facilitate the effect of on-site preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

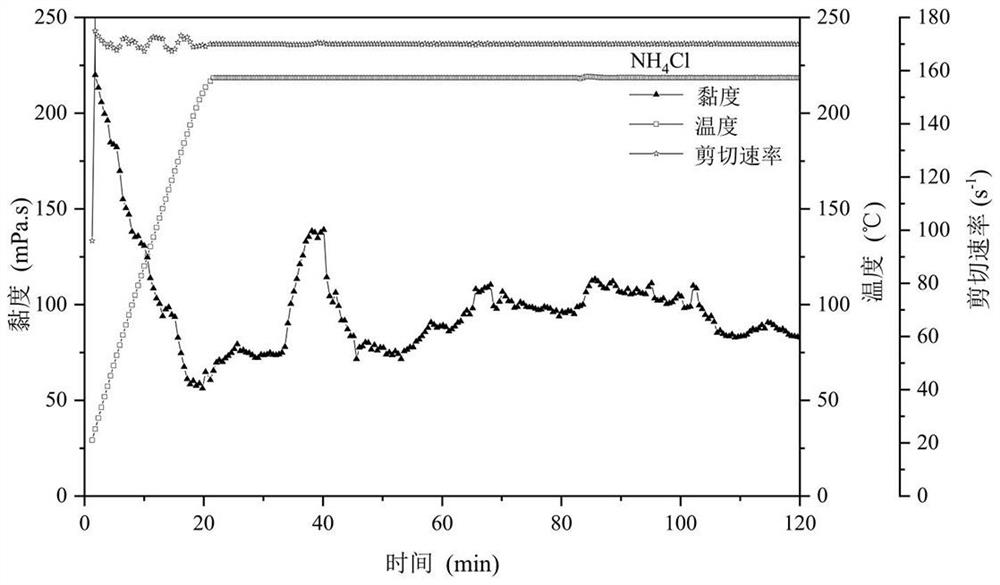

Embodiment 1

[0045] The preparation process of supramolecular star polymers is as follows:

[0046] Step S1: Preparation of β-cyclodextrin modified branched monomer F-β-CD:

[0047] S11: Add freshly dried β-CD (14.0 g, 12.3 mmol) into a three-necked flask, add 100 mL of dry pyridine at room temperature, stir magnetically, and dissolve uniformly. After it was completely dissolved, a pyridine solution of p-toluenesulfonyl chloride (16.9 g, 88.6 mmol) was added under an ice-water bath. After the dropwise addition, the reaction system was warmed to room temperature and reacted for 24 hours. The solvent pyridine was recovered by rotary evaporation, the crude product was poured into a large amount of cold water, and the white precipitate was obtained by suction filtration, which was washed with 100 mL of water and 100 mL of ether respectively; at 62-65 °C, the crude product was stirred in methanol for 30 min, and suction filtered; at 40 °C Vacuum drying to obtain a white solid all 6-position p...

Embodiment 2

[0056] The preparation of the supramolecular star polymer is the same as in Example 1.

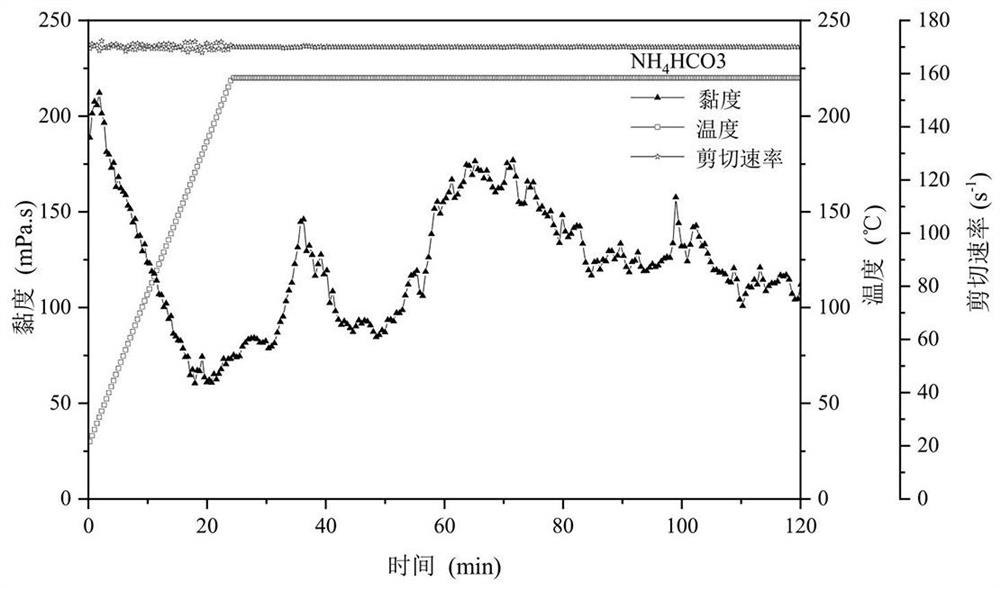

[0057] An ultra-high temperature organic cross-linked fracturing fluid system, the formula of which is calculated in mass percentage as follows: supramolecular star polymer 0.6wt%, formaldehyde solution 0.75wt%, resorcinol 0.025wt%, ammonium bicarbonate 0.1wt% , and the rest is water. The fracturing fluid is obtained after mixing and stirring the components uniformly.

[0058] in the 170s -1 , 220 ℃ to test the apparent viscosity change curve of the fracturing fluid system with time, such as figure 2 shown. from figure 2 It can be seen that the apparent viscosity of the fracturing fluid system first decreased and then increased, and remained stable at the end of the decrease. need.

Embodiment 3

[0060] The preparation of the supramolecular star polymer is the same as in Example 1.

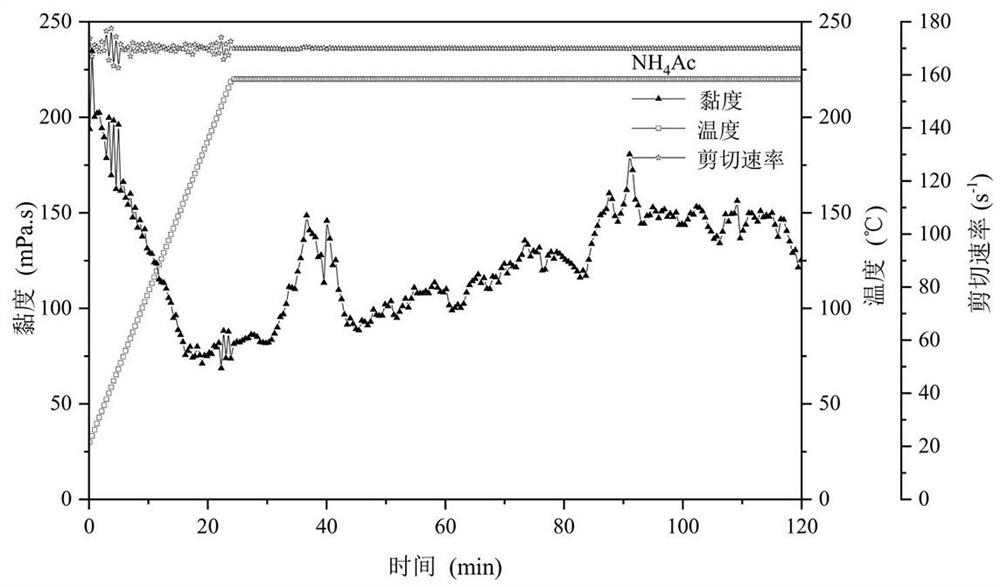

[0061] An ultra-high temperature organic cross-linked fracturing fluid system, the formula of which is calculated in mass percentage as follows: supramolecular star polymer 0.6wt%, formaldehyde solution 0.75wt%, resorcinol 0.025wt%, ammonium acetate 0.1wt%, The rest is water. The fracturing fluid is obtained after mixing and stirring the components uniformly.

[0062] in the 170s -1 , 220 ℃ to test the apparent viscosity change curve of the fracturing fluid system with time, such as image 3 shown. from image 3 It can be seen that the apparent viscosity of the fracturing fluid system first decreased, then increased, and finally remained stable. After 120 min of shearing, the apparent viscosity of the fracturing fluid remained at about 125 mPa·s, which met the needs of ultra-high temperature fracturing. .

[0063] in the 170s -1 , 240 ℃ to test the apparent viscosity change curve o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com