Method for preparing graphene glass

A graphene, graphene film technology, applied in graphene, nano-carbon, coating and other directions, can solve problems such as safety hazards, and achieve the effects of uniform thickness, high quality and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

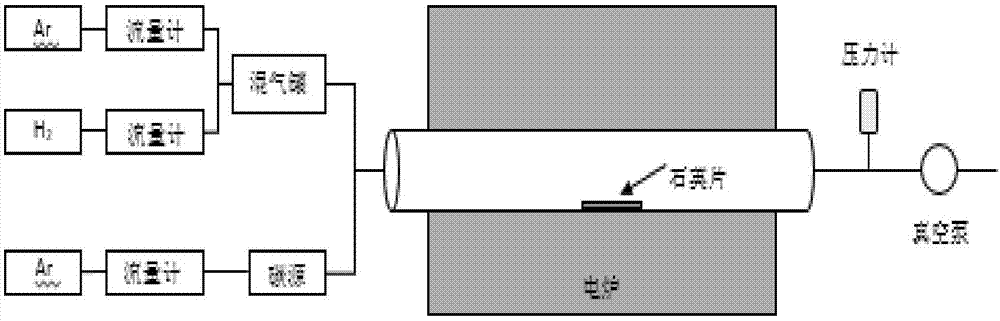

[0033] The method for preparing graphene glass of the present invention comprises:

[0034] Step 1, glass cleaning, ultrasonically clean the glass with water, ethanol, acetone, water, isopropanol, and water respectively, for 3-5 minutes each time (that is, a total time-consuming of 18-30 minutes), and blow dry with nitrogen;

[0035] Step 2. Using the glass as the substrate, in a low-pressure environment, the ambient temperature is raised to 900°C-1100°C, a reducing atmosphere gas is introduced, and then a carbon source gas is introduced according to a flow rate of 10-200 sccm to grow the graphene film. After a period of time, stop feeding the carbon source gas and the reducing atmosphere gas, and the ambient temperature naturally drops to room temperature to obtain a graphene film on the quartz glass. The carbon source gas is at least one of methanol gas and ethanol gas.

[0036] In the method for preparing graphene glass of the present invention, the reducing atmosphere gas ...

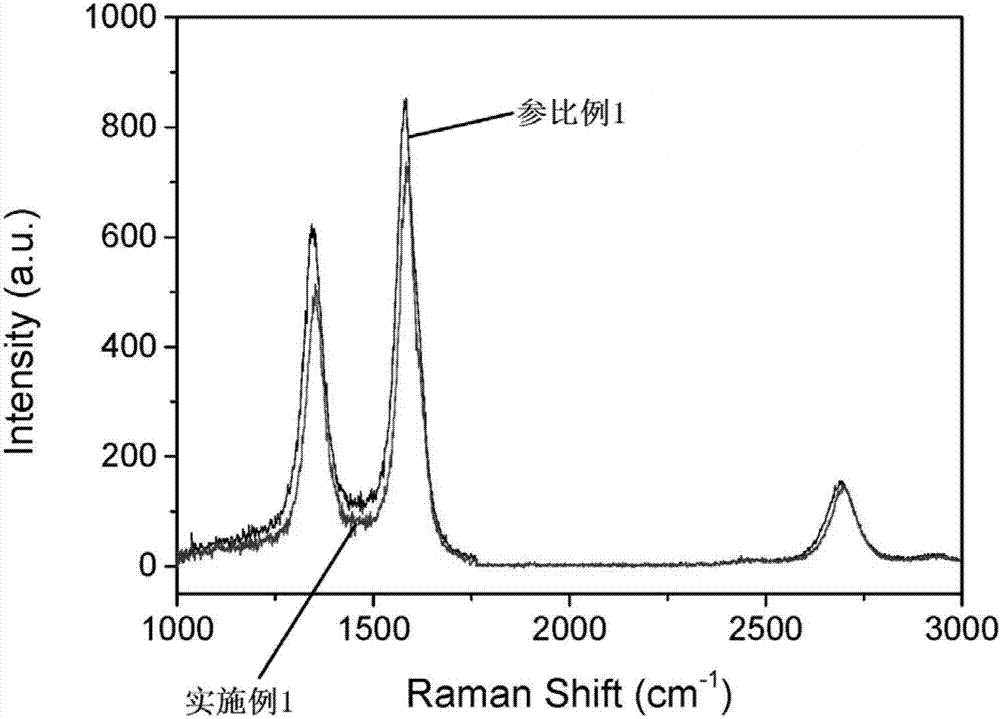

Embodiment 1

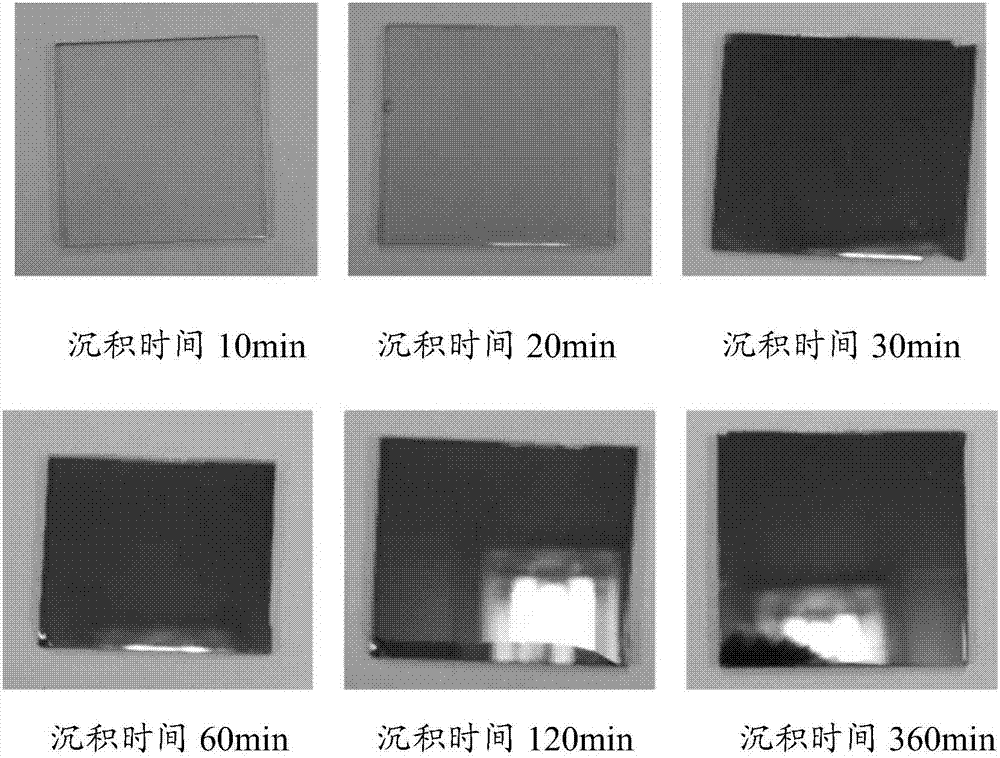

[0055] Example 1: A quartz glass sheet is ultrasonically cleaned with pure water, ethanol, acetone, water, isopropanol, and water for 3 minutes in sequence, and dried with nitrogen; the cleaned quartz glass is placed in a furnace tube of a chemical vapor deposition system, and the tube Set the furnace temperature to 1050°C, and after vacuuming to about 10Pa, clean the entire gas circuit with 500 sccm argon for 5 minutes; turn on the hydrogen, set the argon and flow rate to 475 sccm, the hydrogen flow rate to 25 sccm, and the proportion of hydrogen to argon The volume ratio of the hydrogen mixture is 5%; open the argon gas path loaded with ethanol, adjust the flow rate of the argon gas to 100 sccm, adjust the vacuum pump to make the pressure in the tube furnace about 1000 Pa, keep the growth at a constant temperature for 100 min, and stop feeding the carbon source gas and reducing atmosphere gas, and then naturally cool down to room temperature to obtain the graphene glass provi...

Embodiment 27

[0071] Example 27: According to the process steps of Example 24, after the deposition time is 30 minutes, stop feeding the carbon source gas, keep the reducing gas unobstructed, keep the pressure and temperature constant, and after annealing for 60 minutes, naturally cool down to obtain a quartz glass sheet Graphene with strong adhesion.

[0072] Wipe slowly the graphene glass that embodiment 24 and embodiment 27 obtains with the power of 1N 100 times, the effect that obtains is as follows Figure 5 As shown, obvious friction traces can be observed on the surface of the graphene glass in Example 24, and its absorption has decreased by 21.23%. No obvious friction traces have been observed on the surface of the graphene glass in Example 27, and the absorption has only decreased by 2.15%. Therefore, by increasing the The time in the low-pressure reducing atmosphere can increase the adhesion of graphene to the quartz glass sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com