The method of chitosan modified clay and its application of algae removal technology

A technology of chitosan modification and chitosan solution, applied in the field of water treatment, can solve the problems of not considering the composite synergistic effect of micro-bubble modifiers, unsatisfactory algae removal effect, increasing floc density, etc., so as to shorten the coagulation time. time, increase the flocculation effect, reduce the effect of the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

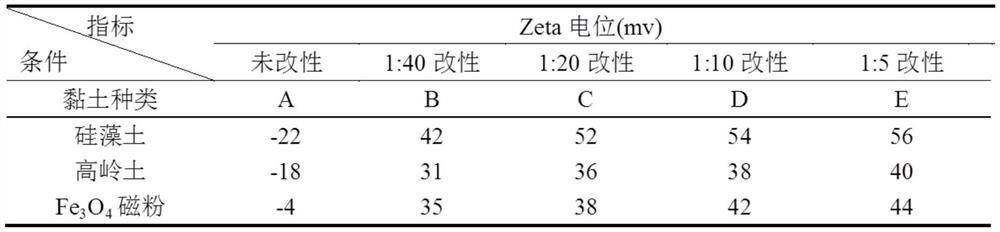

[0038] A modified diatomite and polyaluminum chloride composite coagulant, which is prepared from chitosan solution and diatomite and then compounded with polyaluminum chloride

[0039]The compound method of described chitosan solution is as follows: first measure mass concentration and be 5% hydrochloric acid 10mL, add reactor, under the situation of constantly stirring, add 200mg chitosan again, dissolve and add distilled water and be diluted to 100ml, at temperature The reaction time was stirred at 30°C for 0.5 hour to obtain a dilute chitosan hydrochloric acid solution with a chitosan concentration of 2 mg / mL.

[0040] Chitosan dilute hydrochloric acid solution modified diatomite according to the mass ratio of 1:5. Modified diatomaceous earth and polyaluminum chloride are compounded at a mass ratio of 1:2, with a total dosage of 60mg / L; cetyltrimethylammonium bromide dosage of 1mg / L. The coagulation time is 2min; the reflux ratio of dissolved air and water is 30%; the sep...

Embodiment 2

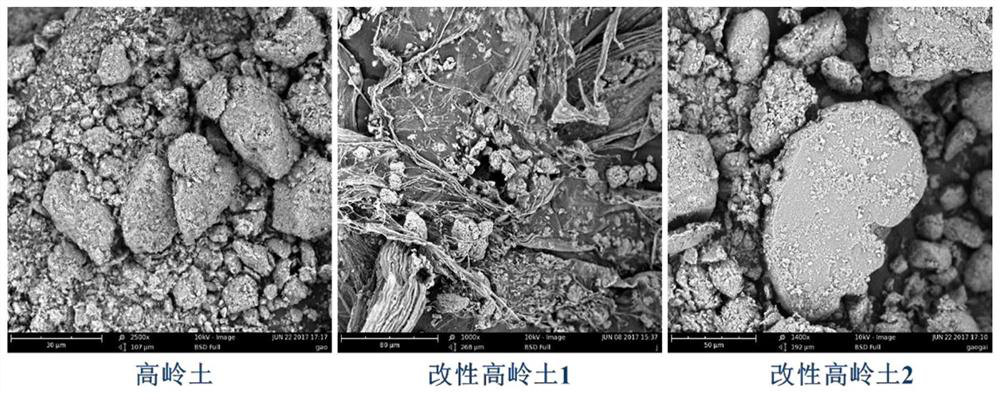

[0045] A modified kaolin and polyferric sulfate composite coagulant, which is prepared from chitosan solution and kaolin and then compounded with polyaluminum sulfate

[0046] The compound method of described chitosan solution is as follows: first measure mass concentration and be 10mL of hydrochloric acid of 1%, add reactor, under the situation of constantly stirring, add 20mg chitosan again, dissolve and add distilled water and dilute to 100ml, at temperature The reaction time was stirred at 15° C. for 1.5 hours to obtain a dilute chitosan hydrochloric acid solution with a chitosan concentration of 0.2 mg / mL.

[0047] Chitosan dilute hydrochloric acid solution modified kaolin at a mass ratio of 1:20. Modified kaolin and polyferric sulfate are compounded at a mass ratio of 1:1, the total dosage is 20mg / L; the dosage of cetyltrimethylammonium bromide is 0.5mg / L. The coagulation time is 4 minutes; the reflux ratio of dissolved air and water is 20%; the separation time in the s...

Embodiment 3

[0052] A modified diatomite and polyferric sulfate composite coagulant, which is prepared from chitosan solution and diatomite and then compounded with polyferric sulfate

[0053] The preparation method of described chitosan solution is as follows: at first measure mass concentration and be 10mL of hydrochloric acid of 2%, add reactor, under the situation of constantly stirring, add 100mg chitosan again, dissolve and add distilled water and be diluted to 100ml, at temperature The reaction time was stirred at 20° C. for 1.0 hour to obtain a dilute chitosan hydrochloric acid solution with a chitosan concentration of 1 mg / mL.

[0054] Diatomite was modified by dilute chitosan hydrochloric acid solution at a mass ratio of 1:40. Modified diatomaceous earth and polyferric sulfate are compounded at a mass ratio of 2:1, with a total dosage of 40mg / L; cetyltrimethylammonium bromide dosage of 1mg / L. The coagulation time is 4 minutes; the reflux ratio of dissolved air and water is 30%; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com