A kind of led-uv ultraviolet light curing wood nano coating and preparation method thereof

A nano-coating and ultraviolet light technology, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., to achieve the effect of low cost, flexible paint film and good sanding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

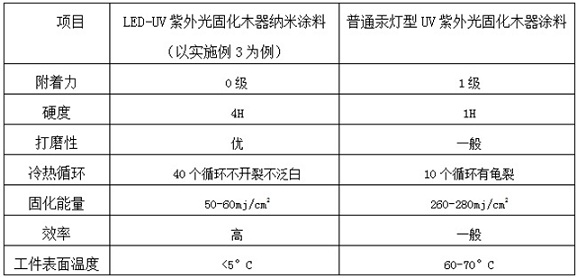

Image

Examples

Embodiment 1

[0052] Polyurethane acrylate cross-linked with pentaerythritol triacrylate and polyisocyanate 30%;

[0053] Fatty acid modified polyester acrylate resin 10%;

[0054] Ethoxylated modified trimethylolpropane triacrylate 20%;

[0055] Dipropylene Glycol Diacrylate 10%;

[0056] UV curable monomer dispersion of nano wear-resistant particles 5%;

[0057] Wetting and dispersing agent 0.2%;

[0058] Nano barium sulfate powder 15%;

[0059] Hydrogen abstraction photoinitiator 4%;

[0060] Active amine 1%;

[0061] Cleavage photoinitiator 4%;

[0062] Leveling agent 0.5%;

[0063] Defoamer 0.2%;

[0064] Inhibitor 0.1%.

[0065] The above-mentioned pentaerythritol triacrylate and polyisocyanate cross-linked urethane acrylate adopts the SM6330 type resin sold by Jiangsu Sanmu Group Company;

[0066] The above-mentioned fatty acid modified polyester acrylate resin adopts 03-849 sold by Swiss RAHN Lahn Company;

[0067] The above-mentioned ethoxylated modified trimethylolpropa...

Embodiment 2

[0076] Polyurethane acrylate cross-linked with pentaerythritol triacrylate and polyisocyanate 30%;

[0077] Fatty acid modified polyester acrylate resin 14%;

[0078] Ethoxylated Trimethylolpropane Triacrylate 22%;

[0079] Dipropylene Glycol Diacrylate 12%;

[0080] UV curable monomer dispersion of nano wear-resistant particles 2%;

[0081] Wetting and dispersing agent 0.2%;

[0082] Nano barium sulfate powder 10%;

[0083] Hydrogen abstraction photoinitiator 4%;

[0084] Active amine 1%;

[0085] Cleavage photoinitiator 4%;

[0086] Leveling agent 0.5%;

[0087] Defoamer 0.2%;

[0088] Inhibitor 0.1%.

[0089] The above-mentioned urethane acrylate resin cross-linked with pentaerythritol triacrylate and polyisocyanate adopts commercially available 6145-100 of Taiwan Changxing Chemical Group Company;

[0090] The polyester acrylate resin modified by the above-mentioned fatty acid adopts YH7297 of Dongguan Haohui Chemical Co., Ltd.;

[0091] The above-mentioned ethox...

Embodiment 3

[0100] Polyurethane acrylate crosslinked with pentaerythritol triacrylate and polyisocyanate 25%;

[0101] Fatty acid modified polyester acrylate resin 15%;

[0102] Ethoxylated modified trimethylolpropane triacrylate 20%;

[0103] Dipropylene Glycol Diacrylate 15%;

[0104] UV curable monomer dispersion of nano wear-resistant particles 5%;

[0105] Wetting and dispersing agent 0.2%;

[0106] Nano barium sulfate powder 10%;

[0107] Hydrogen abstraction photoinitiator 4%;

[0108] Active amine 1%;

[0109] Cleavage photoinitiator 4%;

[0110] Leveling agent 0.4%;

[0111] Defoamer 0.3%;

[0112] Inhibitor 0.1%.

[0113] The urethane acrylate resin formed by the crosslinking of the above-mentioned pentaerythritol triacrylate and polyisocyanate adopts the SM6330 type resin sold by Jiangsu Sanmu Group Company;

[0114] The above-mentioned fatty acid modified polyester acrylate resin adopts resins such as Dongguan Haohui Chemical Co., Ltd. YH7297;

[0115] The above-men...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com