Method for regenerating carbon fiber ultramicroelectrode

An ultra-fine electrode and carbon regeneration technology, applied in the field of bioelectrochemical analysis, can solve the problems of changing electrode microstructure and surface chemistry, and deterioration of electrode response reproducibility and stability, etc., and achieve stable electrochemical performance. Good electrochemical response, simple and convenient activation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

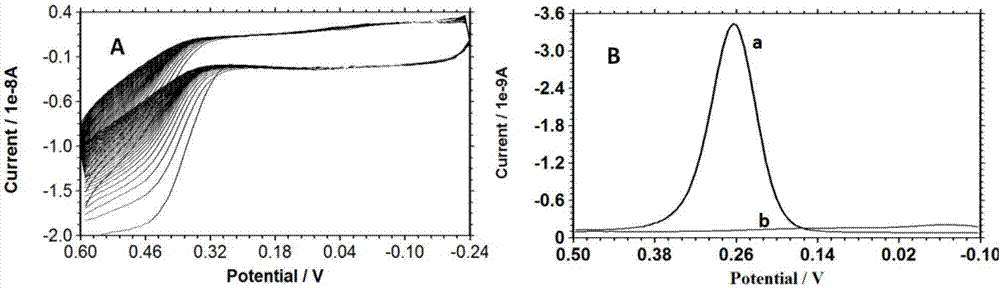

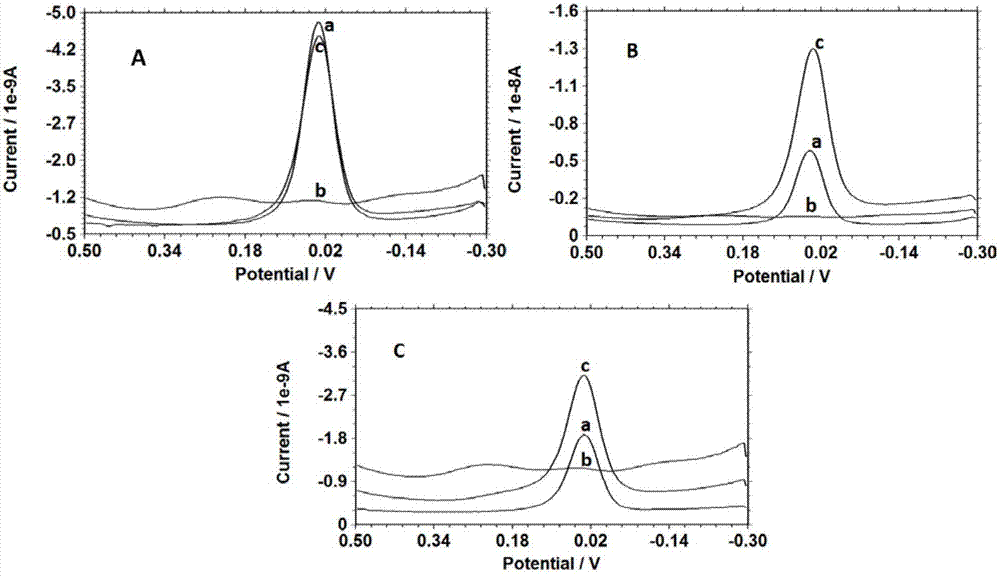

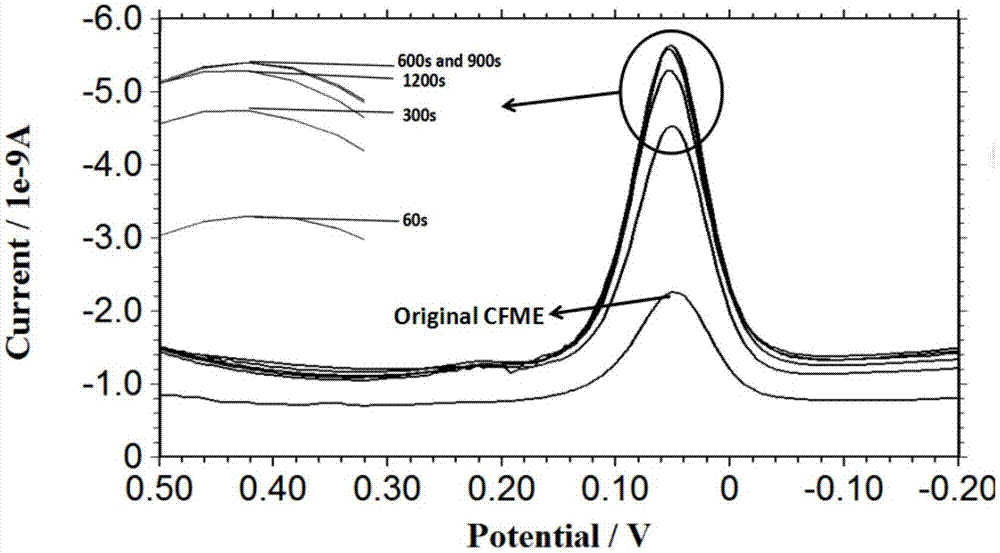

Examples

Embodiment 1

[0029] 1.1 Instruments and reagents

[0030] XD-RFL Laboratory Inverted Microscope (Ningbo Sunny Instrument Co., Ltd.); pHS-3C pH Meter (Shanghai Instrument Scientific Instrument Co., Ltd.); CHI660D Chemical Workstation (Shanghai Chenhua Instrument Company); KQ-400KDE High Power CNC Ultrasonic cleaner; this experiment uses a two-electrode system: a carbon fiber ultra-micro electrode is the working electrode, and an Ag / AgCl electrode is the reference electrode.

[0031] Carbon fiber (6 μm in diameter, Jilin Shenzhou Carbon Fiber Co., Ltd.), absolute ethanol (analytical grade, Tianjin Pharmaceutical Company), dopamine (DA, Sigma), norepinephrine (NE, Sigma), ascorbic acid (AA, analytical grade, Sinopharm Chemical Reagent Co., Ltd.), DA was made into 1.0×10 with absolute ethanol as solvent -2 The mother liquor of mol / L is standby. Five serotonin (5-HT, Sigma), with 0.1mol / L HClO 4 Configured as 1.0×10 -3 mol / L mother solution, stored in a refrigerator at 4°C, and diluted with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com