Liquid metal-macromolecule printable ink and preparation and printing methods thereof

A liquid metal and printing ink technology, which is applied in metal pattern materials, printed circuit manufacturing, printed circuits, etc., can solve the problems of restricting the popularization and application of liquid metal, poor wettability of flexible substrates, and difficulty in pure liquid metal, and achieves a simple activation method. Convenience, reduced surface tension, improved printability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

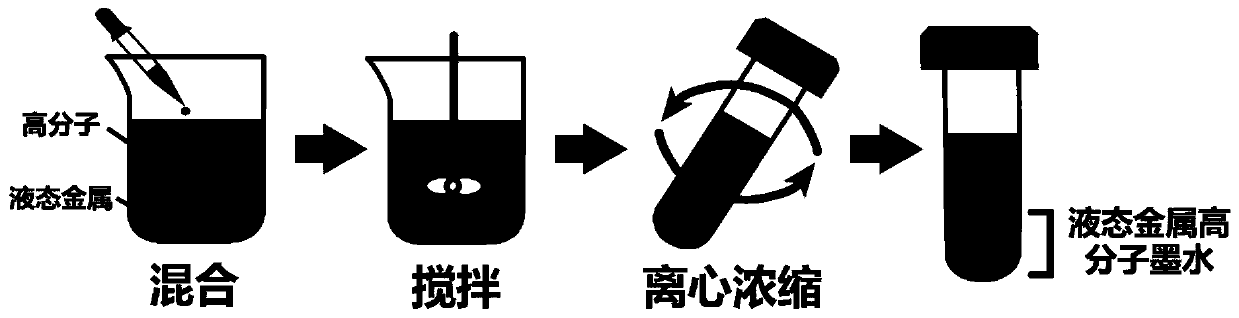

[0039] A magnetic liquid metal printing ink provided by the present invention is formed by mixing and concentrating liquid metal and polymer; wherein the liquid metal is gallium and gallium binary, ternary, or quaternary alloys, preferably gallium-indium binary alloys , by weight, the content of gallium is 35-90 parts, the rest is indium; or gallium indium tin ternary alloy, by weight, the content of gallium is 35-80 parts, the content of indium is 10-20 parts , and the rest is tin (this embodiment adopts gallium-indium binary alloy, the content of gallium is 50%, and the rest is indium). Among them, the polymer is preferably PDMS, and the PDMS precursor has a low viscosity, which is convenient for stirring and concentrating. as attached figure 1 As shown, the ink can be obtained after mixing liquid metal with polymer, stirring and concentrating. When liquid metal is mixed with macromolecule, by weight, liquid metal content is preferably 20-70 parts, and all the other are ma...

Embodiment 2

[0041] A magnetic liquid metal printing ink provided by the present invention is formed by mixing and concentrating liquid metal and polymer; wherein the liquid metal is gallium and gallium binary, ternary, or quaternary alloys, preferably gallium-indium binary alloys , by weight, the content of gallium is 35-90 parts, the rest is indium; or gallium indium tin ternary alloy, by weight, the content of gallium is 35-80 parts, the content of indium is 10-20 parts , and the rest is tin (in this embodiment, the gallium indium tin ternary alloy is selected, the content of gallium is 50 parts by weight, the content of indium is 20%, and the rest is tin). Among them, the polymer is preferably PDMS, and the PDMS precursor has a low viscosity, which is convenient for stirring and concentrating. as attached figure 1 As shown, the ink can be obtained after mixing liquid metal with polymer, stirring and concentrating. When liquid metal is mixed with macromolecule, by weight, liquid metal...

Embodiment 3

[0043] A magnetic liquid metal printing ink provided by the present invention is formed by mixing and concentrating liquid metal and polymer; wherein the liquid metal is gallium and gallium binary, ternary, or quaternary alloys, preferably gallium-indium binary alloys , by weight, the content of gallium is 35-90 parts, the rest is indium; or gallium indium tin ternary alloy, by weight, the content of gallium is 35-80 parts, the content of indium is 10-20 parts , and the rest is tin (this embodiment adopts gallium-indium binary alloy, the content of gallium is 70%, and the rest is indium). Among them, the polymer is preferably PDMS, and the PDMS precursor has a low viscosity, which is convenient for stirring and concentrating. as attached figure 1 As shown, the ink can be obtained after mixing liquid metal with polymer, stirring and concentrating. When mixing the liquid metal with the polymer, the content of the liquid metal is preferably 20-70 parts by weight, and the rest i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com